Preparation method of nickel phosphide/foamed nickel electrochemical functional hydrogen evolution material

A technology of nickel phosphide and nickel foam, which is applied in chemical instruments and methods, physical/chemical process catalysts, liquid chemical plating, etc., can solve the problems of high energy consumption and great harm to human body, and achieve excellent performance, high efficiency and stable properties , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

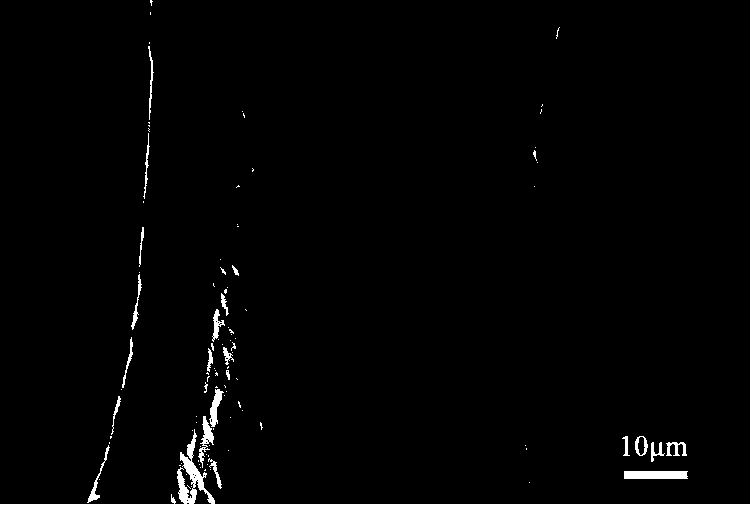

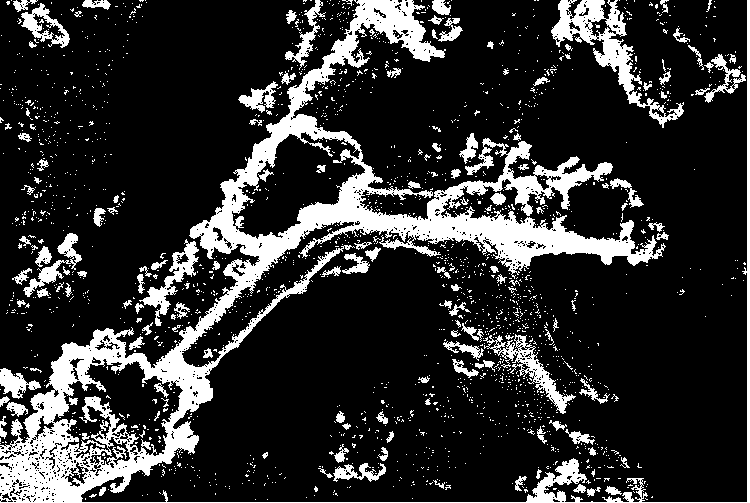

[0034] (1) Pretreatment of nickel foam collector:

[0035] ① Cutting and pre-treatment of nickel foam:

[0036] First, cut the commercially available nickel foam into small pieces with a length and width of 2cm, then place the cut nickel foam in a beaker filled with 50mL of acetone, seal the mouth of the container with plastic wrap, and then place the beaker in ultrasonic cleaning Ultrasonic treatment is carried out in the ultrasonic cleaner, the power of the ultrasonic cleaner is 90W, and the ultrasonic treatment time is 30min, so as to degrease the nickel foam sheet at room temperature; after that, the nickel foam sheet that has been degreased with acetone under ultrasonication is taken out from the beaker , it was cleaned 5 times with deionized water, then the foamed nickel sheet that was treated with acetone and cleaned was placed in a beaker containing 50 mL of 2mol / L hydrochloric acid for etching, and the mouth of the container was sealed with a plastic wrap, and then P...

Embodiment 2

[0073] (1) Pretreatment of nickel foam collector:

[0074] ① Cutting and pre-treatment of nickel foam:

[0075] First, cut the commercially available nickel foam into small pieces with a length and width of 2cm, then place the cut nickel foam in a beaker filled with 50mL of acetone, seal the mouth of the container with plastic wrap, and then place the beaker in ultrasonic cleaning Ultrasonic treatment is carried out in the ultrasonic cleaner, the power of the ultrasonic cleaner is 90W, and the ultrasonic treatment time is 30min, so as to degrease the nickel foam sheet at room temperature; after that, the nickel foam sheet that has been degreased with acetone under ultrasonication is taken out from the beaker , it was cleaned 5 times with deionized water, then the foamed nickel sheet that was treated with acetone and cleaned was placed in a beaker containing 50 mL of 2mol / L hydrochloric acid for etching, and the mouth of the container was sealed with a plastic wrap, and then P...

Embodiment 3

[0108] (1) Pretreatment of nickel foam collector:

[0109] ① Cutting and pre-treatment of nickel foam:

[0110] First, cut the commercially available nickel foam into small pieces with a length and width of 2cm, then place the cut nickel foam in a beaker filled with 50mL of acetone, seal the mouth of the container with plastic wrap, and then place the beaker in ultrasonic cleaning Ultrasonic treatment is carried out in the ultrasonic cleaner, the power of the ultrasonic cleaner is 90W, and the ultrasonic treatment time is 30min, so as to degrease the nickel foam sheet at room temperature; after that, the nickel foam sheet that has been degreased with acetone under ultrasonication is taken out from the beaker , it was cleaned 5 times with deionized water, then the foamed nickel sheet that was treated with acetone and cleaned was placed in a beaker containing 50 mL of 2mol / L hydrochloric acid for etching, and the mouth of the container was sealed with a plastic wrap, and then P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com