LiMnPO4 hollow microsphere with controllable structure and preparation method and application thereof

A hollow microsphere and reaction kettle technology, applied in structural parts, active material electrodes, electrical components, etc., can solve problems such as uneven dispersion, obstruction, and irregular agglomeration, and achieve easy control of reaction conditions, accurate structure regulation, and synthesis. simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

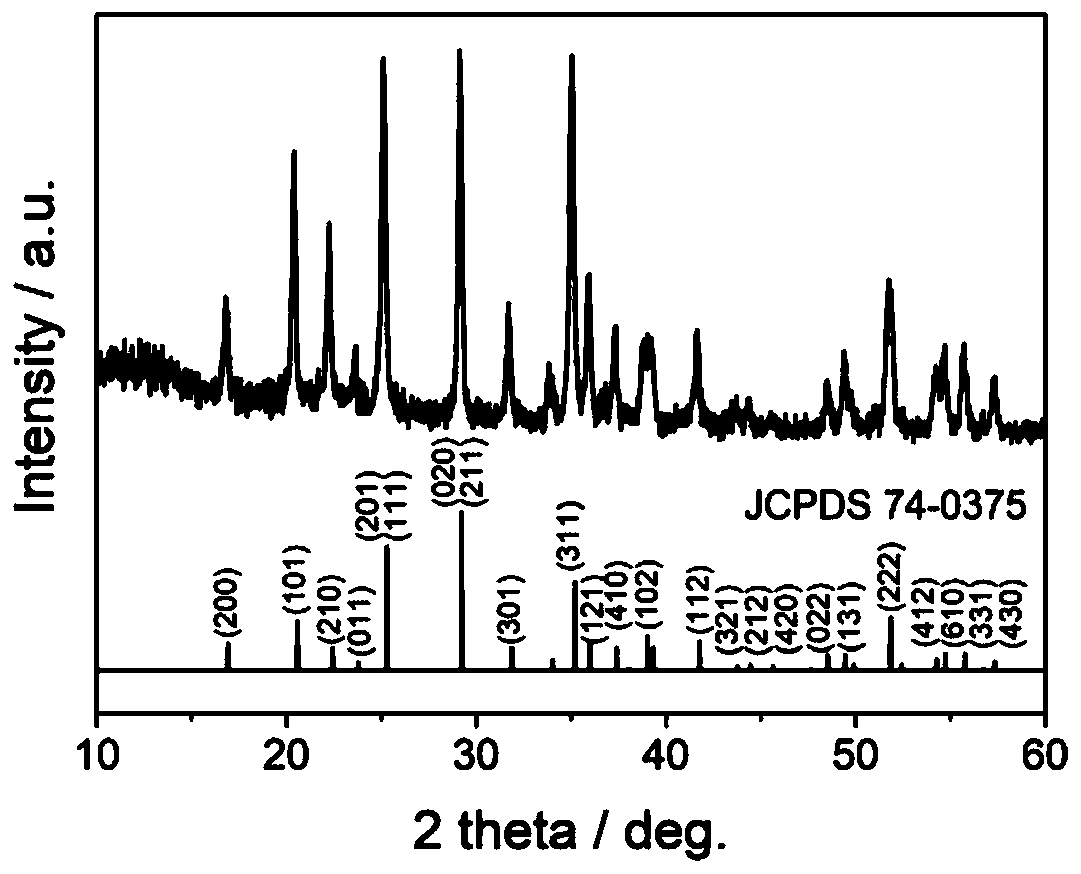

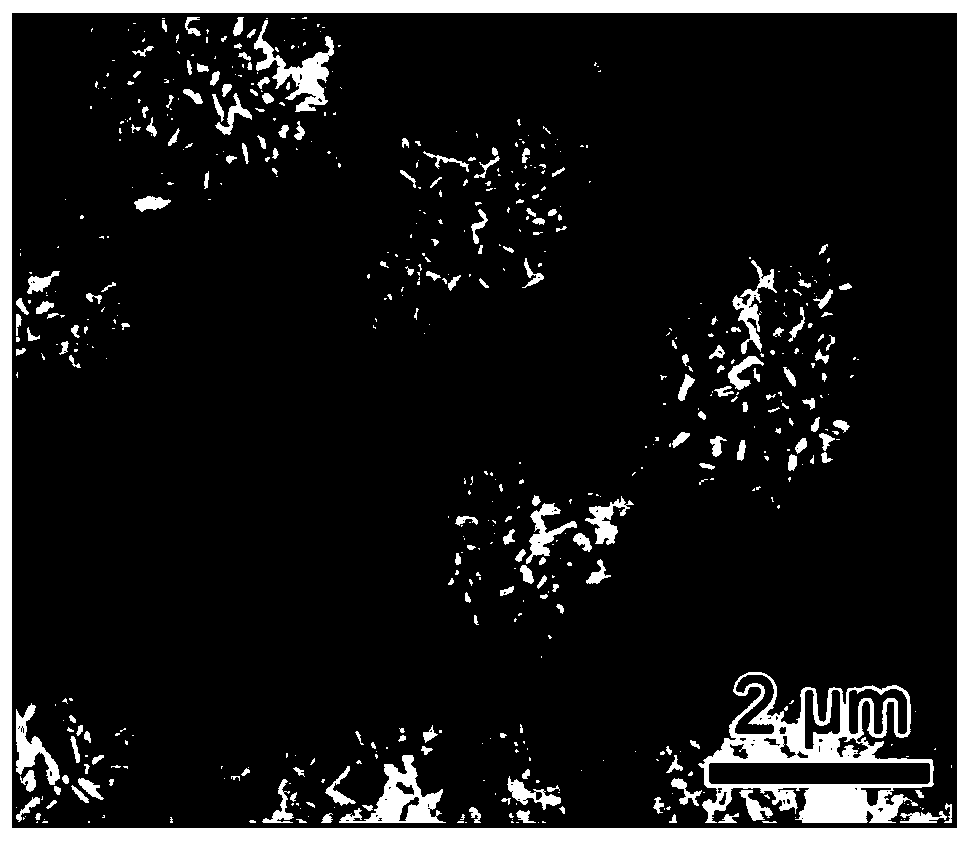

[0033] Embodiment 1: provide a kind of LiMnPO 4 The preparation method of the hollow microspheres with the radially ordered assembly structure of nano-flaky crystal grains is specifically completed according to the following steps:

[0034] step : First, prepare a mixed solvent with 8ml of diethylene glycol and 32ml of deionized water. Then, 80 mmol of sodium hydroxide, 21 mmol of lithium acetate dihydrate and 7 mmol of ammonium dihydrogen phosphate were sequentially added to the mixed solvent at a stirring speed of 1000 rpm. Then, react under stirring state for 30min. Finally, the product was separated by filtration to obtain the solid precipitate in the product, and then the solid precipitate was washed 4 times with deionized water and 1 time with absolute ethanol to obtain the washed solid precipitate and then vacuum-dried at 60°C for 12 hours to obtain Li with a diameter of about 2 μm 3 PO 4 hollow microspheres.

[0035] step : First, prepare a mixed solvent with 2...

Embodiment 2

[0040] Embodiment 2: provide a kind of LiMnPO 4 The preparation method of hollow microspheres with nano-prismatic crystal grain radially ordered assembly structure is specifically completed according to the following steps:

[0041] step : First, prepare a mixed solvent with 8ml of diethylene glycol and 32ml of deionized water. Then, 80 mmol of sodium hydroxide, 21 mmol of lithium acetate dihydrate and 7 mmol of ammonium dihydrogen phosphate were sequentially added to the mixed solvent at a stirring speed of 1000 rpm. Then, react under stirring state for 30min. Finally, the product was separated by filtration to obtain the solid precipitate in the product, and then the solid precipitate was washed 4 times with deionized water and 1 time with absolute ethanol to obtain the washed solid precipitate and then vacuum-dried at 60°C for 12 hours to obtain Li with a diameter of about 2 μm 3 PO 4 hollow microspheres.

[0042] step : First, prepare a mixed solvent with 20ml eth...

Embodiment 3

[0046] Embodiment 3: provide a kind of LiMnPO 4 The preparation method of hollow microspheres with radially disordered assembly structure of nano-prismatic grains is specifically completed according to the following steps:

[0047] step : First, prepare a mixed solvent with 8ml of diethylene glycol and 32ml of deionized water. Then, 80 mmol of sodium hydroxide, 21 mmol of lithium acetate dihydrate and 7 mmol of ammonium dihydrogen phosphate were sequentially added to the mixed solvent at a stirring speed of 1000 rpm. Then, react under stirring state for 30min. Finally, the product was separated by filtration to obtain the solid precipitate in the product, and then the solid precipitate was washed 4 times with deionized water and 1 time with absolute ethanol to obtain the washed solid precipitate and then vacuum-dried at 60°C for 12 hours to obtain Li with a diameter of about 2 μm 3 PO 4 hollow microspheres.

[0048] step : First, prepare a mixed solvent with 20ml ethy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com