High-activity high-stability IrFe nano alloy composite material, preparation method thereof, catalyst and application of composite material or preparation method or catalyst

A nano-alloy and composite material technology, which is applied in the field of electrochemical hydrogen evolution nano-alloy catalyst technology, to achieve the effects of convenient operation, long working time and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

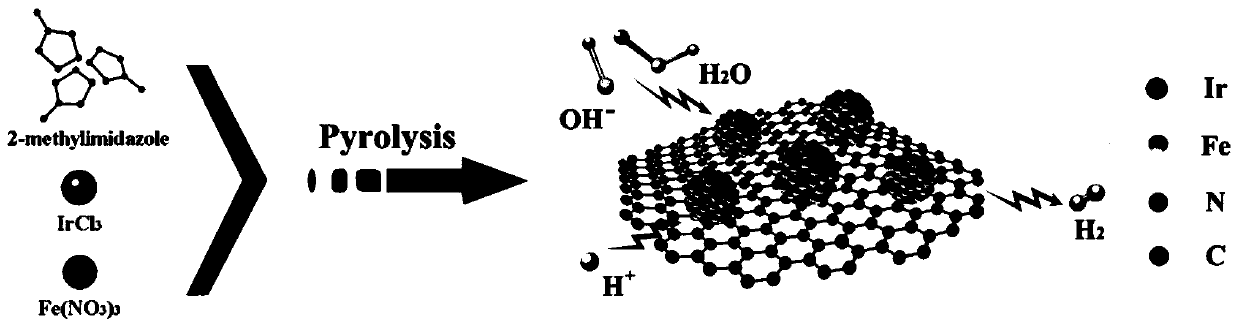

[0081] The present invention also provides a kind of preparation method of IrFe nano-alloy composite material, comprises the following steps:

[0082] 1) After mixing Fe-MOFs, soluble iridium source and solvent, obtain the precursor of Fe-MOFs modified by iridium;

[0083] 2) under a reducing atmosphere, the iridium-modified Fe-MOFs precursor obtained in the above steps is heat-treated to obtain an intermediate;

[0084] 3) After etching the intermediate obtained in the above steps, an IrFe nano-alloy composite material is obtained.

[0085] The selection, composition and structure of the material in the above-mentioned IrFe nano-alloy composite material preparation method of the present invention, and corresponding optimal principle, and the selection, composition and structure of the material in the aforementioned IrFe nano-alloy composite material, and the corresponding optimal principle are all preferred Correspondence can be performed, and details will not be repeated he...

Embodiment 1

[0121] 1. Dissolve 404mg of ferric nitrate nonahydrate in 25mL of methanol to form solution A, dissolve 278mg of dimethylimidazole and 50mg of polyvinylpyrrolidone (PVP) in 25mL of methanol to form solution B, and dissolve B under stirring conditions The solution was added dropwise to the A solution;

[0122] 2. Add 1mL of IrCl under stirring condition 3 aqueous solution (10mg / mL) and stirred for a period of time, centrifuged and vacuum-dried to obtain the iridium-modified Fe-zif precursor;

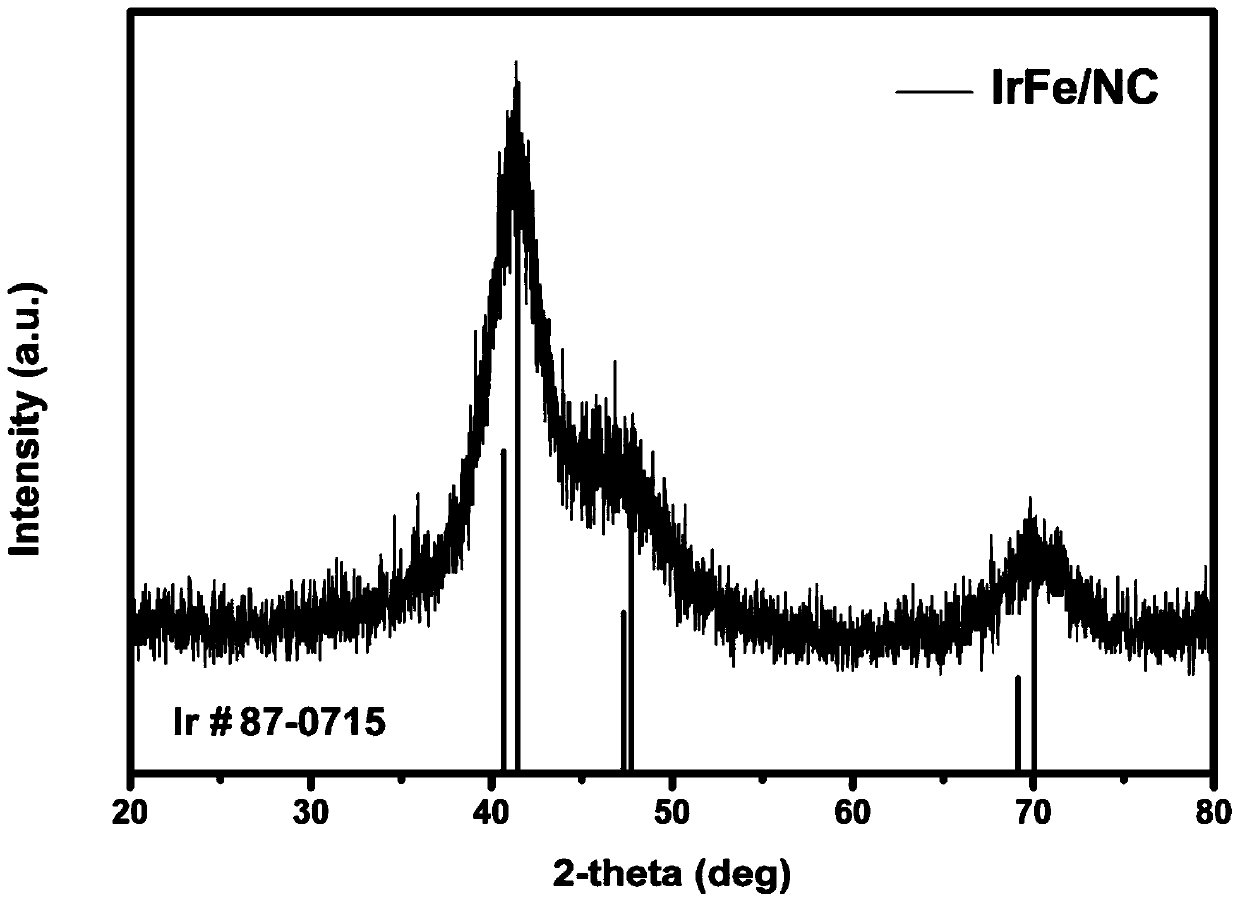

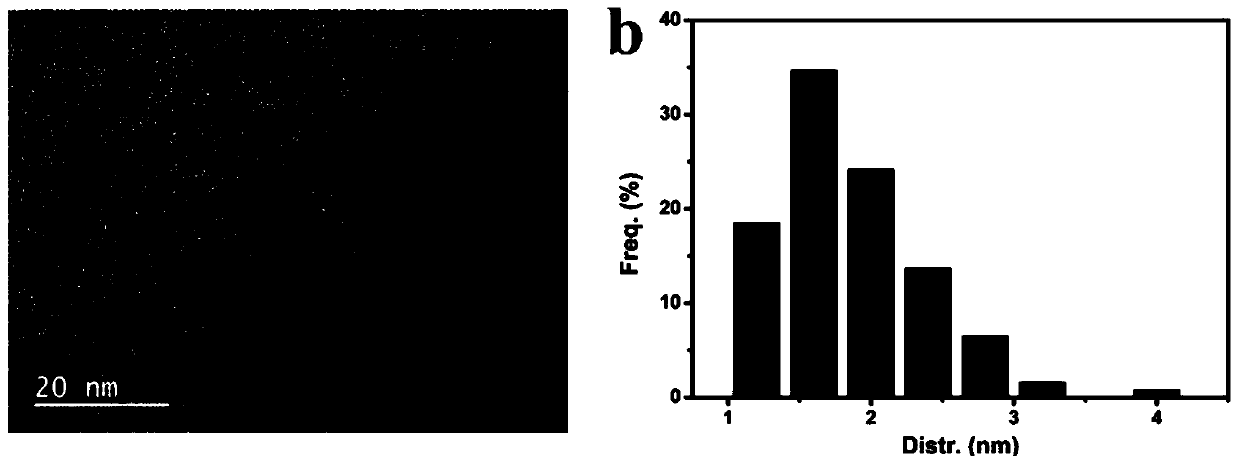

[0123] 3. Place the iridium-modified Fe-zif precursor in a tube furnace under Ar / H 2 In the atmosphere (hydrogen volume ratio 5%), the temperature was raised to 600 ° C and kept for 1 hour, cooled to room temperature, etched with 3M hydrochloric acid solution overnight, centrifugally washed and dried, and the ultra-small IrFe nano-alloy composite material supported by nitrogen-doped carbon layer was obtained ( IrFe / NC).

[0124] see figure 1 , figure 1 It is a schematic flow diagram ...

Embodiment 2

[0145] Electrocatalytic hydrogen evolution

[0146] The IrFe / NC prepared in Example 1 is used to make a three-electrode system, and the electrochemical hydrogen evolution performance test is carried out to the nano-alloy composite in alkaline solution (1MKOH).

[0147] A gold sheet was selected as the counter electrode, Ag / AgCl was used as the reference electrode, a glassy carbon electrode was used as the working electrode, the catalyst was loaded on the glassy carbon electrode, and the loading capacity of the catalyst was 0.285 mg cm -2 . Current density up to 100 mA cm -2 The required overpotential is the criterion for judging the performance of the catalyst.

[0148] see Figure 11 , Figure 11 HER polarization curves of IrFe / NC, 40% Pt / C, 20% Ir / C and Fe / NC samples prepared for the present invention under the same test in 1M KOH electrolyte.

[0149] Depend on Figure 11 It can be seen that the performance of IrFe / NC prepared by the present invention is the best, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com