Process for extracting metallic antimony from antimony soot

A technology for extracting metals and soot, which is applied in the field of extracting metal antimony from antimony soot, can solve the problems of low qualified rate of sodium pyroantimonate products, high operating costs, and high antimony leaching rate, and achieves low production costs and high comprehensive recovery. , the effect of environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

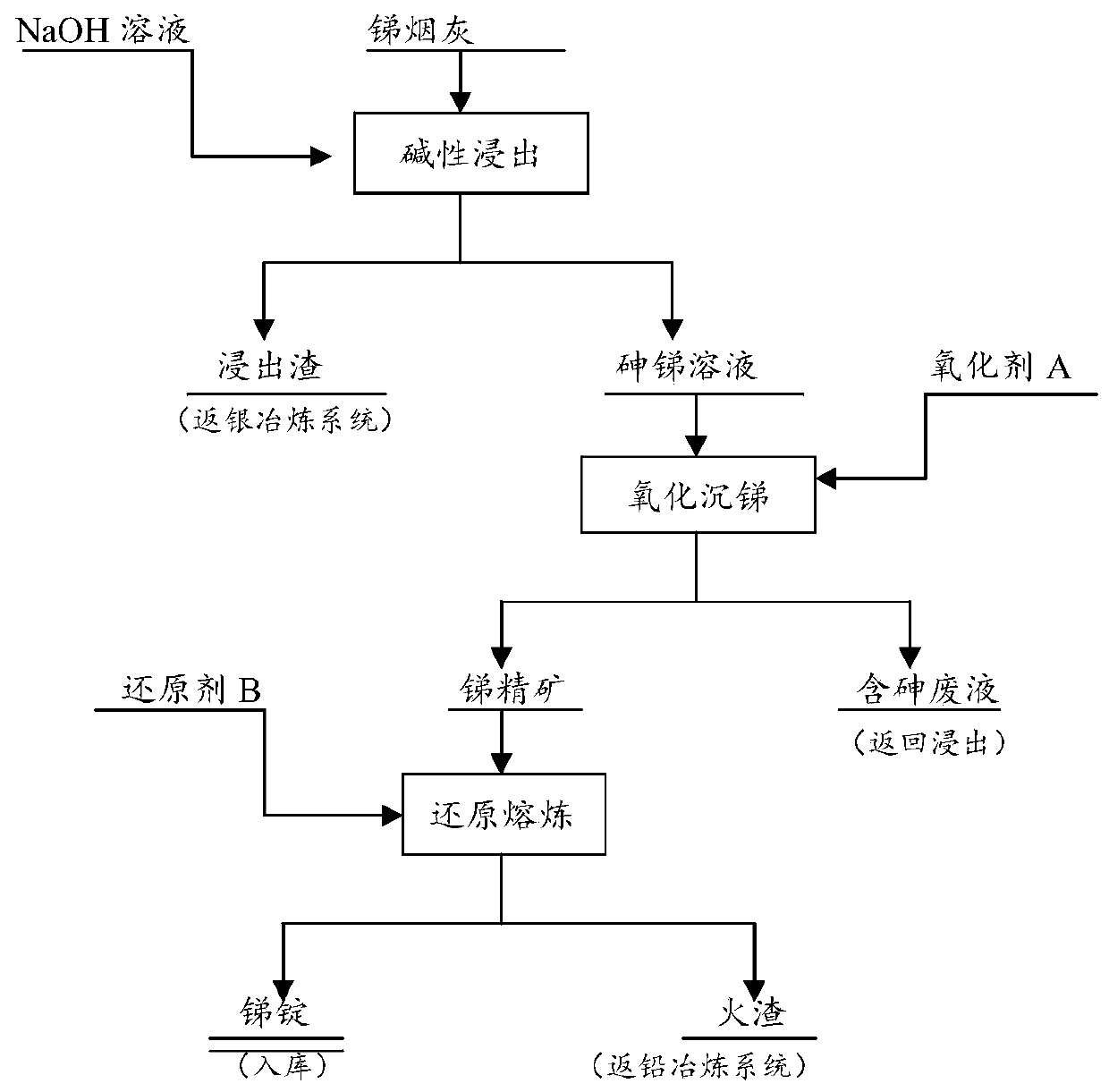

[0024] Embodiment 1 of the present invention is: a kind of technology that extracts metal antimony from antimony soot, such as figure 1 shown, including the following steps:

[0025] S1. After mixing and leaching antimony soot and sodium hydroxide solution, liquid-solid separation is carried out to obtain leaching slag and arsenic-antimony solution, and the leaching slag is directly returned to the silver smelting system to smelt and recover heavy metals;

[0026] S2. Add oxidant A to the arsenic-antimony solution obtained after the liquid-solid separation in step S1 to oxidize and deposit antimony. After the reaction is completed, perform liquid-solid separation operation again to obtain antimony concentrate and arsenic-containing waste liquid, and arsenic-containing waste liquid Return for leaching, if the arsenic concentration in the arsenic-containing waste liquid is high, open-circuit treatment is performed directly;

[0027] S3. Reduction: add reducing agent B to the an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com