Aluminum-chromium-boron alloy target material and preparation method thereof

A technology of aluminum-boron alloy and alloy target, which is applied in metal material coating process, ion implantation plating, coating, etc., can solve the problem of difficult to obtain high-quality and high-density targets, and uneven density distribution inside hot-pressed targets , It is difficult to ensure the uniformity of the product, etc., to achieve the effect of large specifications, small grains, and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

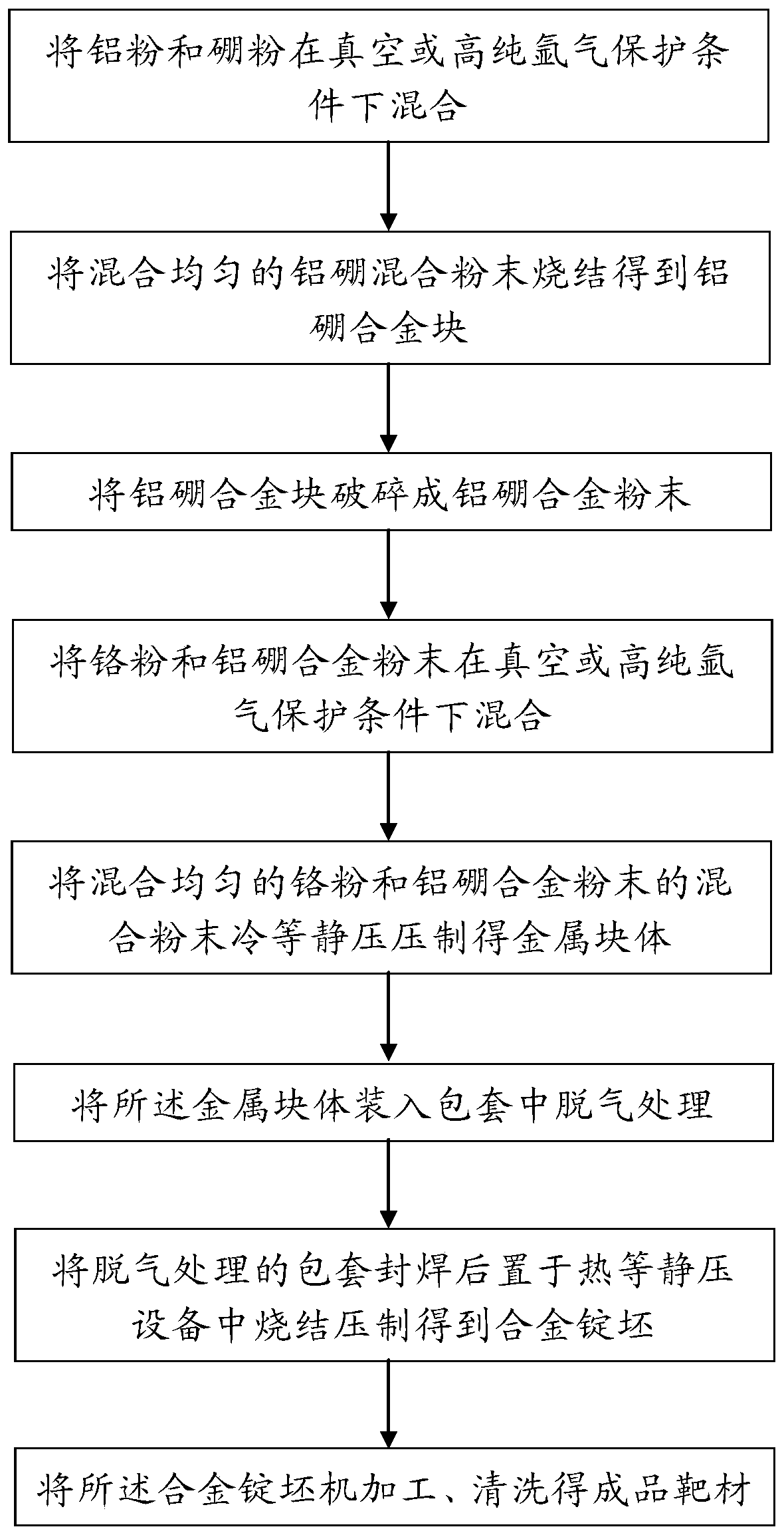

[0028] See figure 1 , The present invention also provides a method for preparing an aluminum-chromium-boron alloy target, including the following steps:

[0029] Step 1) Powder preparation: use aluminum powder with a purity of 99.5% or more and an average particle size of 10-30um and a boron powder with a purity of 99.5% or more and an average particle size of 10-15um in a V-type mixer or Mixing in the three-dimensional mixer for 4-6 hours, and the mixing process is carried out under vacuum or high-purity argon protection conditions to prevent the powder raw materials from being oxidized during the mixing process.

[0030] Step 2) Sintering: Put the uniformly mixed aluminum and boron mixed powder into a vacuum sintering furnace, heat up to 1200-1600°C, control the temperature rise rate at 100-150°C / h, hold for 3-5h, and then cool down to room temperature along with the furnace to obtain Aluminum boron alloy block.

[0031] Step 3) Crushing and powdering: the sintered aluminum-boron...

Embodiment 1

[0039] The aluminum-chromium-boron alloy target provided by the embodiment of the present invention is made of the following atomic percentage raw materials: 60% aluminum, 30% chromium, and 10% boron. The preparation method includes the following steps:

[0040] Weigh boron powder with a purity of 99.5% and an average particle size of 10μm and aluminum powder with a purity of 99.5% and an average particle size of 30um, and mix them in a three-dimensional mixture according to the mass ratio of aluminum powder: boron powder = 15:1wt% Mix in the machine for 4 hours, and pour in high-purity argon for protection during the mixing process.

[0041] Put the mixed powder into a vacuum sintering furnace at a temperature of 1400°C and hold for 2 hours.

[0042] The sintered aluminum-boron alloy block is crushed and ball milled to make 100 mesh powder.

[0043] Weigh chromium powder with a purity of 99.5% and an average particle size of 106um, and 100 mesh aluminum boron powder, and mix them in...

Embodiment 2

[0050] The aluminum-chromium-boron alloy target provided by the embodiment of the present invention is made of the following atomic percentage raw materials: aluminum 52%, chromium 28%, and boron 20%. The preparation method includes the following steps:

[0051] Weigh boron powder with a purity of 99.5% and an average particle size of 10μm and an aluminum powder with a purity of 99.5% and an average particle size of 20um. According to the mass ratio of aluminum powder: boron powder = 6.5:1wt%, mix them in the three-dimensional mixer Mix for 4 hours, and pour in high-purity argon for protection during mixing.

[0052] Put the mixed powder into a vacuum sintering furnace at a temperature of 1300°C and hold for 3 hours.

[0053] The sintered aluminum-boron alloy block is crushed and ball milled to make 100 mesh powder.

[0054] Weigh chromium powder with a purity of 99.5% and an average particle size of 75um, and 100 mesh aluminum boron powder, and mix them in a mass ratio of chromium p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com