Cell-free freeze-drying preparation for in-vitro protein synthesis, and preparation method and application of cell-free freeze-drying preparation

A technology for protein synthesis and freeze-dried preparations, applied in the biological field, can solve the problems of reduced protein synthesis capacity, inconvenient operation, affecting protein activity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

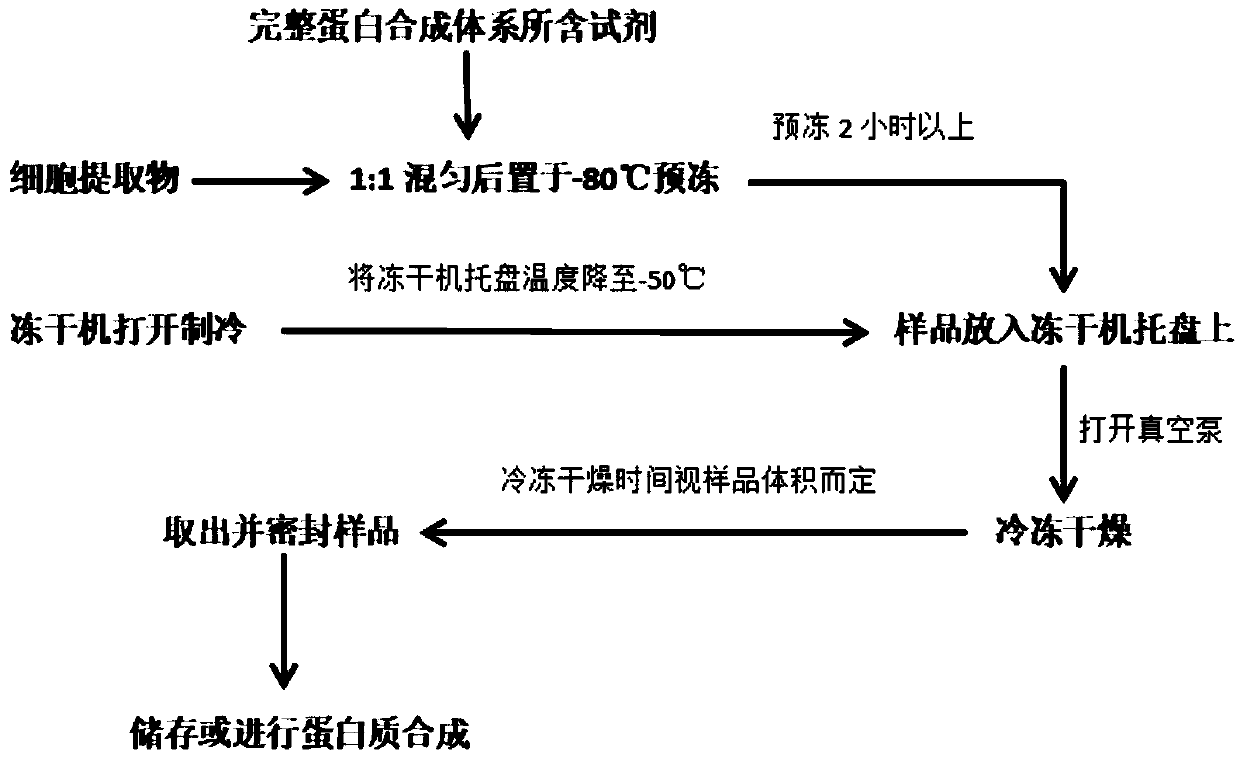

Method used

Image

Examples

preparation example Construction

[0210] In the present invention, the preparation method of the yeast cell extract is not limited, and a preferred preparation method includes the following steps:

[0211] (i) providing yeast cells;

[0212] (ii) washing the yeast cells to obtain washed yeast cells;

[0213] (iii) subjecting the washed yeast cells to destructive treatment to obtain crude yeast extract;

[0214] (iv) performing solid-liquid separation on the crude yeast extract to obtain the liquid part, which is the yeast cell extract.

[0215] In the present invention, the solid-liquid separation method is not particularly limited, and a preferred method is centrifugation.

[0216] In a preferred embodiment, said centrifugation is performed in a liquid state.

[0217] In the present invention, the centrifugation conditions are not particularly limited, and a preferred centrifugation condition is 5000-100000g, preferably 8000-30000g.

[0218] In the present invention, the centrifugation time is not particu...

Embodiment 1

[0244] Example 1 Preparation of Yeast Cell Extract by Liquid Nitrogen Fragmentation Method

[0245] 1.1 Primary seed culture: inoculate shake flask culture medium with strains frozen at -80°C, culture at 30°C, 200rpm until logarithmic growth phase.

[0246] 1.2 Secondary seed culture: Take an appropriate amount of primary seed bacterial liquid to inoculate secondary seeds, and cultivate at 30°C and 200rpm until logarithmic growth phase.

[0247] 1.3 Batch culture stage: Inoculate the secondary seed bacterial liquid into the fermenter, culture at 30°C for 10-12 hours, enter the fed-batch culture stage, and collect the cell culture when the OD600 value is 50-55.

[0248] 1.4 Pre-cool the cultured cell culture in the ice-water mixture for 10-30 minutes.

[0249] 1.5 Centrifuge the pre-cooled cell culture in 1.4 in a cryogenic centrifuge under the centrifugation conditions: 3,000g, 10min, 4°C to obtain yeast cells.

[0250] 1.6 Use the pre-cooled Washing buffer to resuspend the ...

Embodiment 2

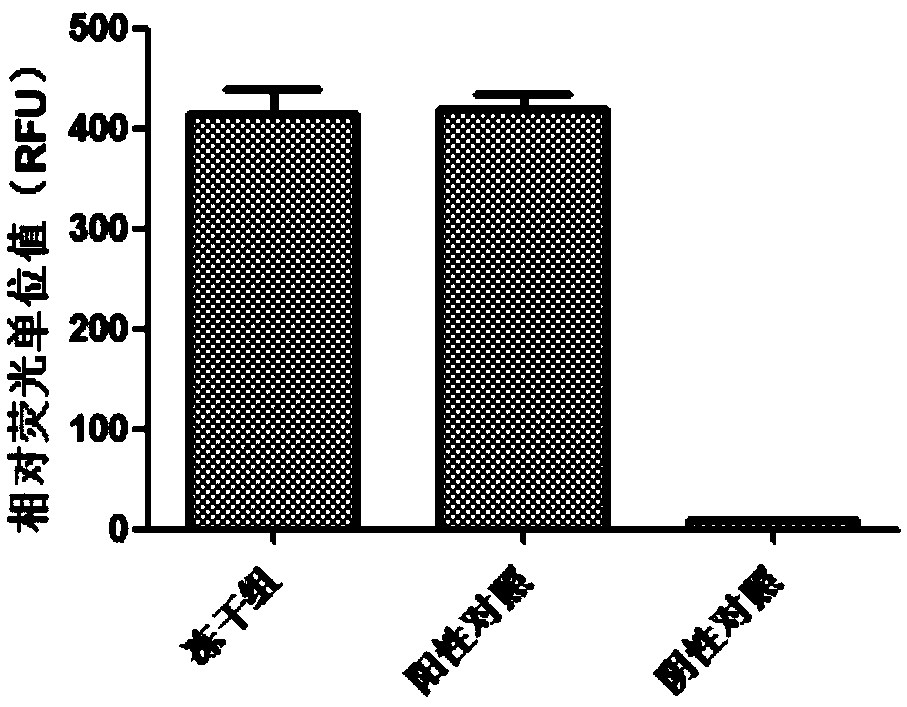

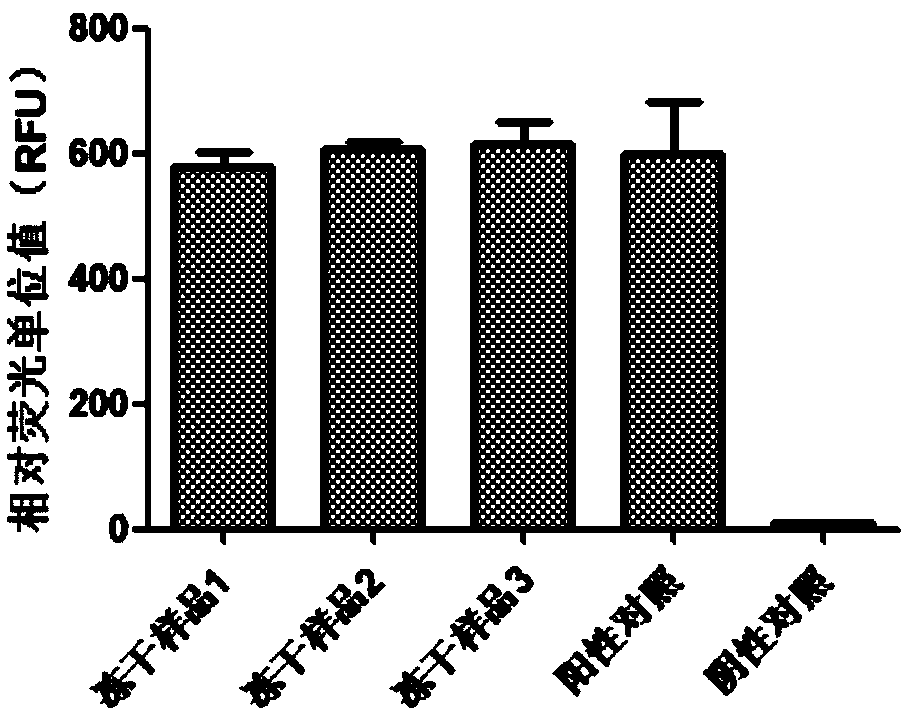

[0258] Example 2 In vitro protein synthesis system

[0259] 2.1 In vitro protein synthesis system: final concentration of 22mM 4-hydroxyethylpiperazineethanesulfonic acid with a pH of 7-8, 30-150mM potassium acetate, 1.0-5.0mM magnesium acetate, 1.5-4mM nucleoside triphosphate mixture (adenoside Purine nucleoside triphosphate, guanosine triphosphate, cytidine nucleoside triphosphate and uridine nucleoside triphosphate), 0.08-0.24mM amino acid mixture (glycine, alanine, valine, leucine, Isoleucine, Phenylalanine, Proline, Tryptophan, Serine, Tyrosine, Cysteine, Methionine, Asparagine, Glutamine, Threonine, Aspartic Acid, Glutamine acid, lysine, arginine and histidine), 1.7mM dithiothreitol, 10-40mM glucose, 200-400mM starch, 0.002-0.02mg / mL amylase, 20-25mM tripotassium phosphate, 0.027 -0.054 mg / mL T7 RNA polymerase, 1%-4% polyethylene glycol, and finally 50% volume of yeast cell extract solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com