Concrete recycled aggregate and preparation process thereof

A concrete regeneration and preparation technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of restricting the development of recycled concrete, high water absorption of recycled aggregates, and reduced concrete strength Enhanced binding strength, improved water resistance, and reduced porosity and water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

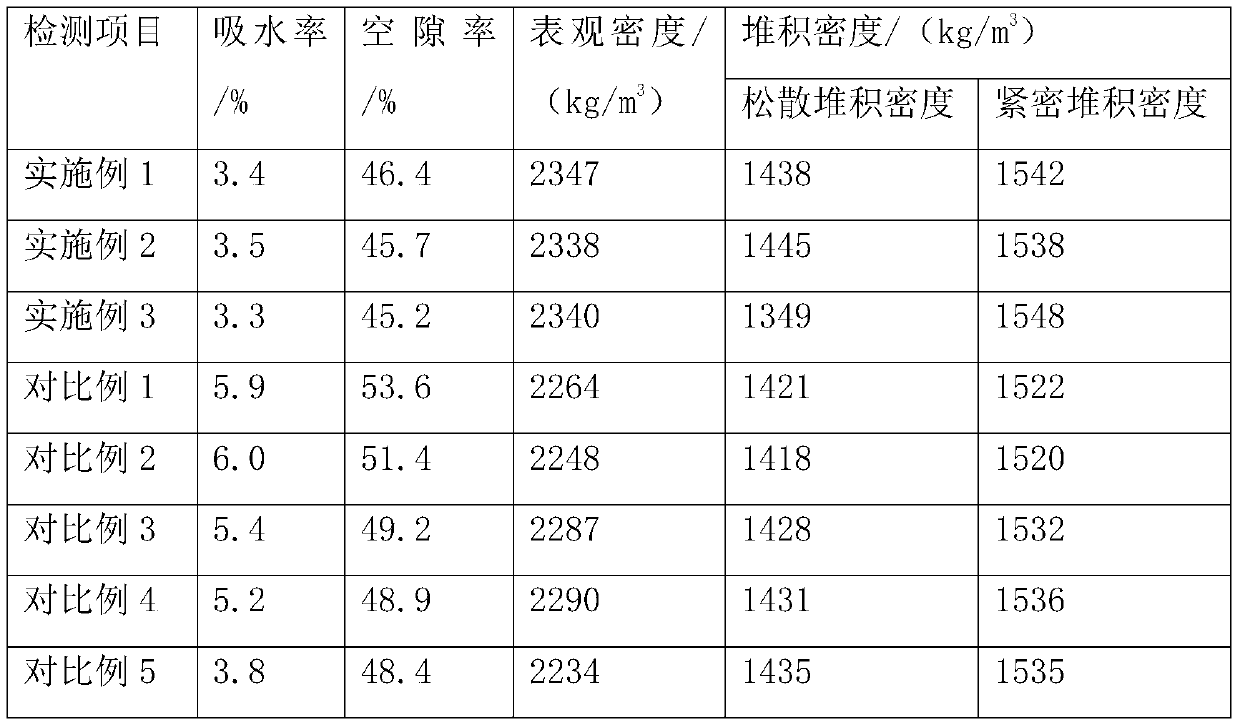

Examples

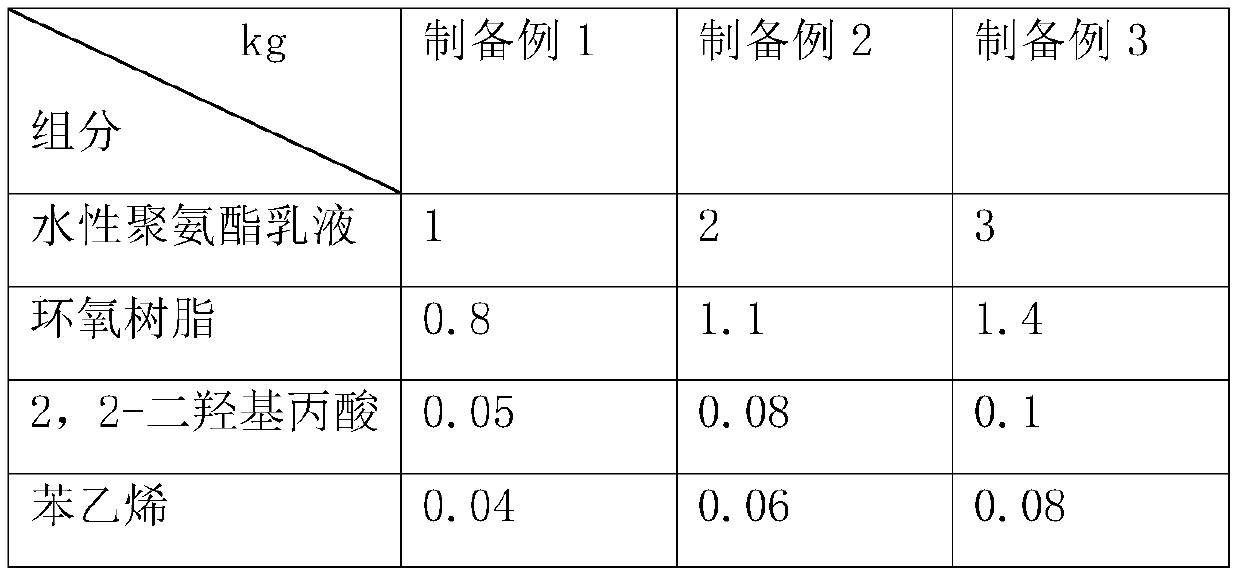

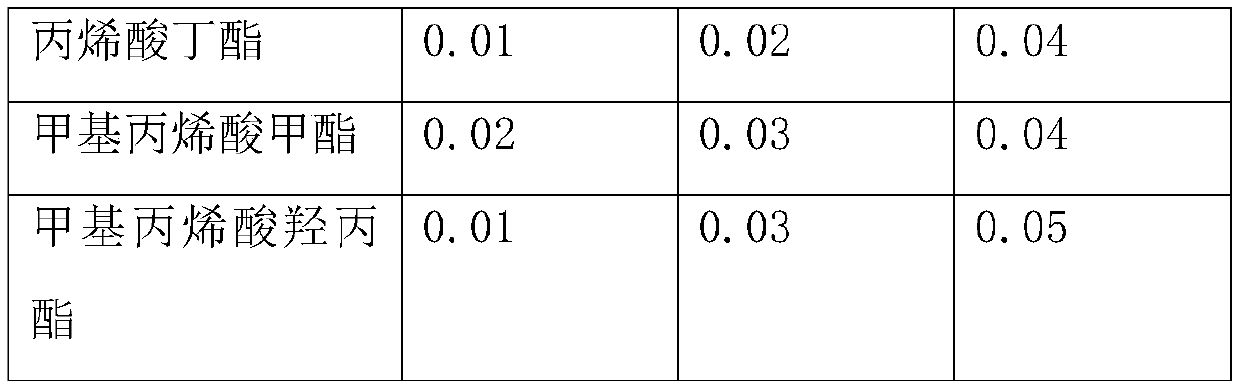

preparation example 1-3

[0042] In the preparation example 1-3, the water-based polyurethane emulsion is selected from the water-based polyurethane emulsion of F81 sold by Henan Bikai Water-based New Material Co., Ltd., and the epoxy resin is selected from the epoxy resin of E-44 sold by Guangzhou Daoning Chemical Co., Ltd. resin.

preparation example 1

[0043] Preparation Example 1: Add 0.8kg of epoxy resin and 0.05kg of 2,2-dihydroxypropionic acid to 1kg of water-based polyurethane emulsion according to the dosage in Table 1, add 0.04kg of styrene and 0.01kg of acrylic acid slowly to 110°C A mixed solution of butyl ester, 0.02kg methyl methacrylate and 0.01kg hydroxypropyl methacrylate, the temperature is slowly raised during the dropwise addition, and after the drop is completed, the temperature is raised to 120°C for 6 hours, and cooled to room temperature to obtain epoxy resin Modified waterborne polyurethane.

[0044] The raw material ratio of epoxy resin modified polyurethane in the preparation example 1-3 of table 1

[0045]

[0046]

preparation example 2

[0047] Preparation Example 2: According to the dosage in Table 1, add 1.1kg epoxy resin and 0.08kg 2,2-dihydroxypropionic acid to 2kg water-based polyurethane emulsion, add to 130°C, slowly add dropwise 0.06kg styrene, 0.02kg A mixed solution of butyl acrylate, 0.03kg methyl methacrylate and 0.03kg hydroxypropyl methacrylate, the temperature rises slowly during the dropwise addition, and after the dropwise rises to 120°C for 7 hours, then cools to room temperature to obtain epoxy Resin-modified waterborne polyurethane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com