A kind of molten salt chemically synthesized carbon powder and its preparation method and application

A technology for molten salt chemistry and carbon synthesis, which is used in carbon preparation/purification, electrochemical generators, structural parts, etc., can solve problems such as complex synthesis processes, and achieve the effects of simple equipment operation, high-quality preparation, and beneficial recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] A preparation method of molten salt chemically synthesized carbon powder, comprising the following steps:

[0083] Step 1, molten salt dehydration treatment

[0084] Weigh 50gCaCl 2 The molten salt was dried in a crucible furnace at 300°C for 24 hours to obtain a dried and dehydrated molten salt;

[0085] Step 2, the preparation of calcium carbide, calcium carbonate raw material and the assembly of reaction device

[0086] Weigh 10gCaCO 3 , and dried at 300°C for 24 hours to obtain dry molten salt. Weigh 13gCaC 2 , crushed in an inert atmosphere, and dried at 80°C.

[0087] Step 3, carbon powder synthesis reaction

[0088] (1) Follow CaC from the bottom of the crucible 2 , CaCl 2 and CaCO 3 The sequence is laid layer by layer into a crucible with a diameter of 50 mm, the reactor is closed, high-purity argon gas is introduced, and circulating cooling water is introduced into the sealing flange of the closed reactor at the same time.

[0089] (2) The temperature...

Embodiment 2

[0093] A kind of preparation method of molten salt chemically synthesized carbon powder body, with embodiment 1, difference is:

[0094] (1) The temperature used in step 2 is 900°C.

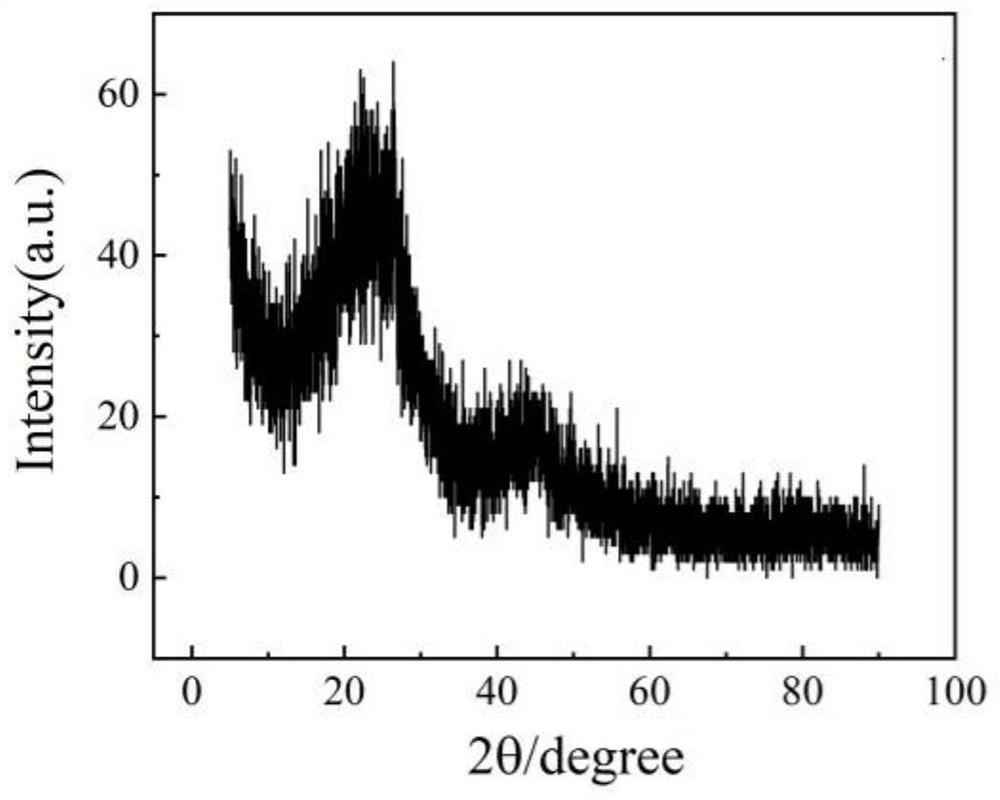

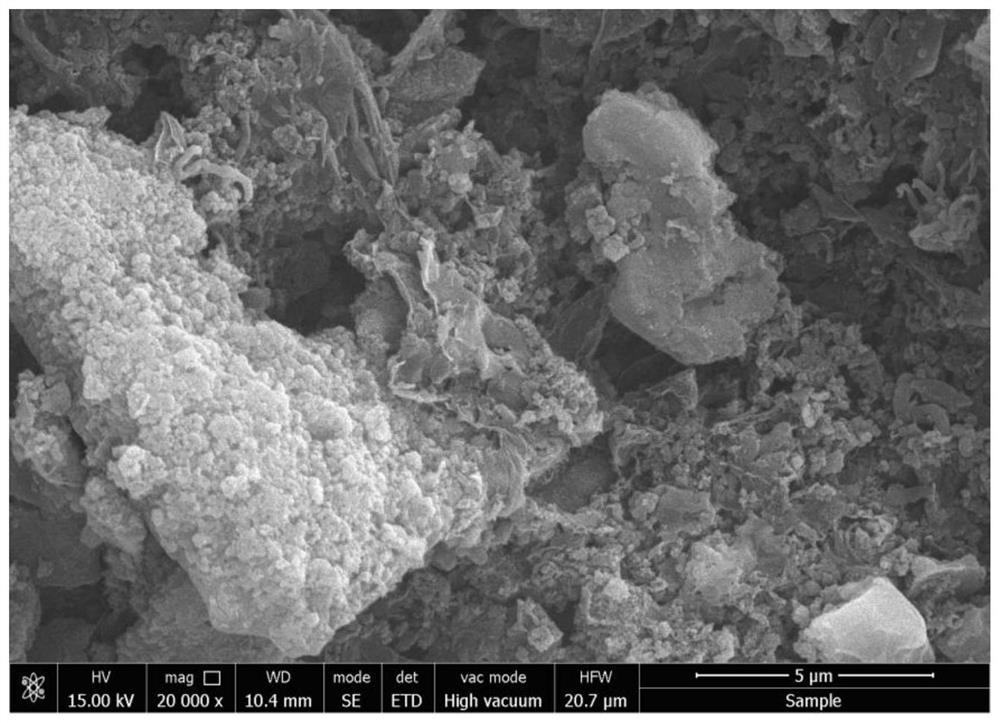

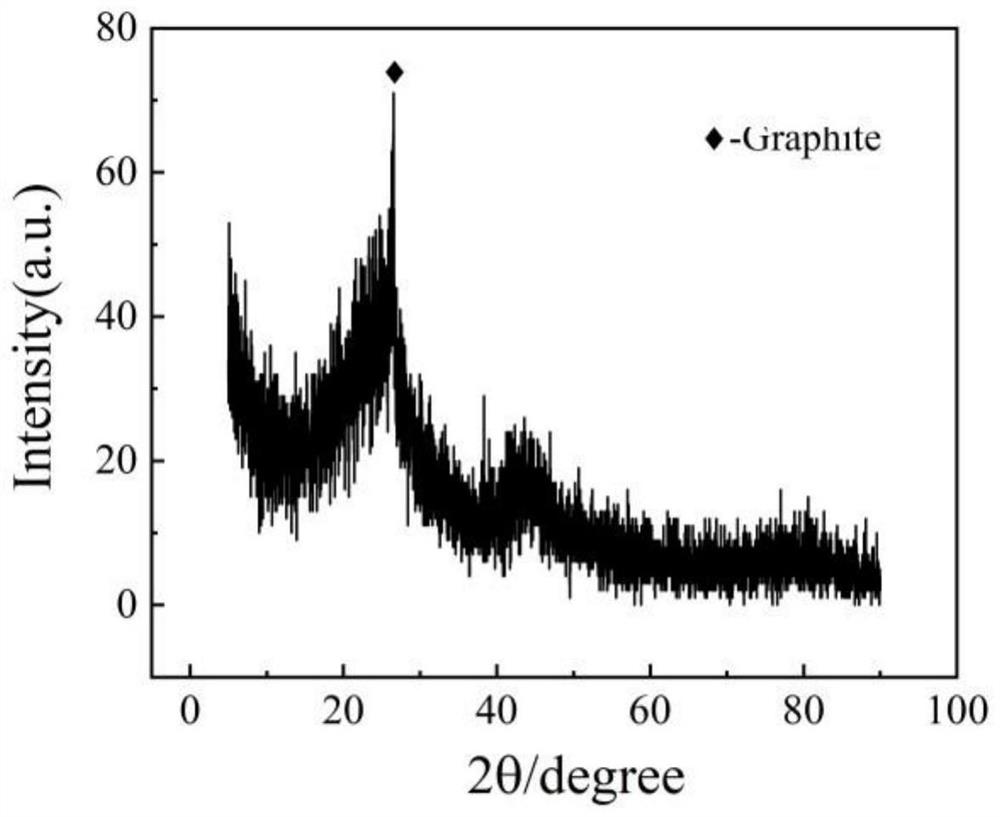

[0095] The obtained product structure is a composite structure comprising amorphous carbon and graphite phase, its XRD sees image 3 , whose SEM is Figure 4 ,from Figure 4 It can be seen that the morphology is uniform spherical particles.

Embodiment 3

[0097]A kind of preparation method of molten salt chemically synthesized carbon powder body, with embodiment 1, difference is:

[0098] (1) The molten salt used in step 1 is CaCl 2 -NaCl eutectic mixed molten salt, the mass is 500g, and the two molten salts are evenly mixed before drying;

[0099] (2) CaCO in step 2 3 Mass is 70g, CaC 2 The mass is 91g;

[0100] (3) In step 3 (1), the diameter of the corundum crucible is 100mm;

[0101] (4) CaC in step 3(1) 2 , CaCl 2 -NaCl and CaCO 3 The mixing method is uniform mixing;

[0102] (4) The reaction temperature in step 3(2) is 650° C., and the reaction time is 6 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com