Aminated glass fibers, preparation method and applications thereof

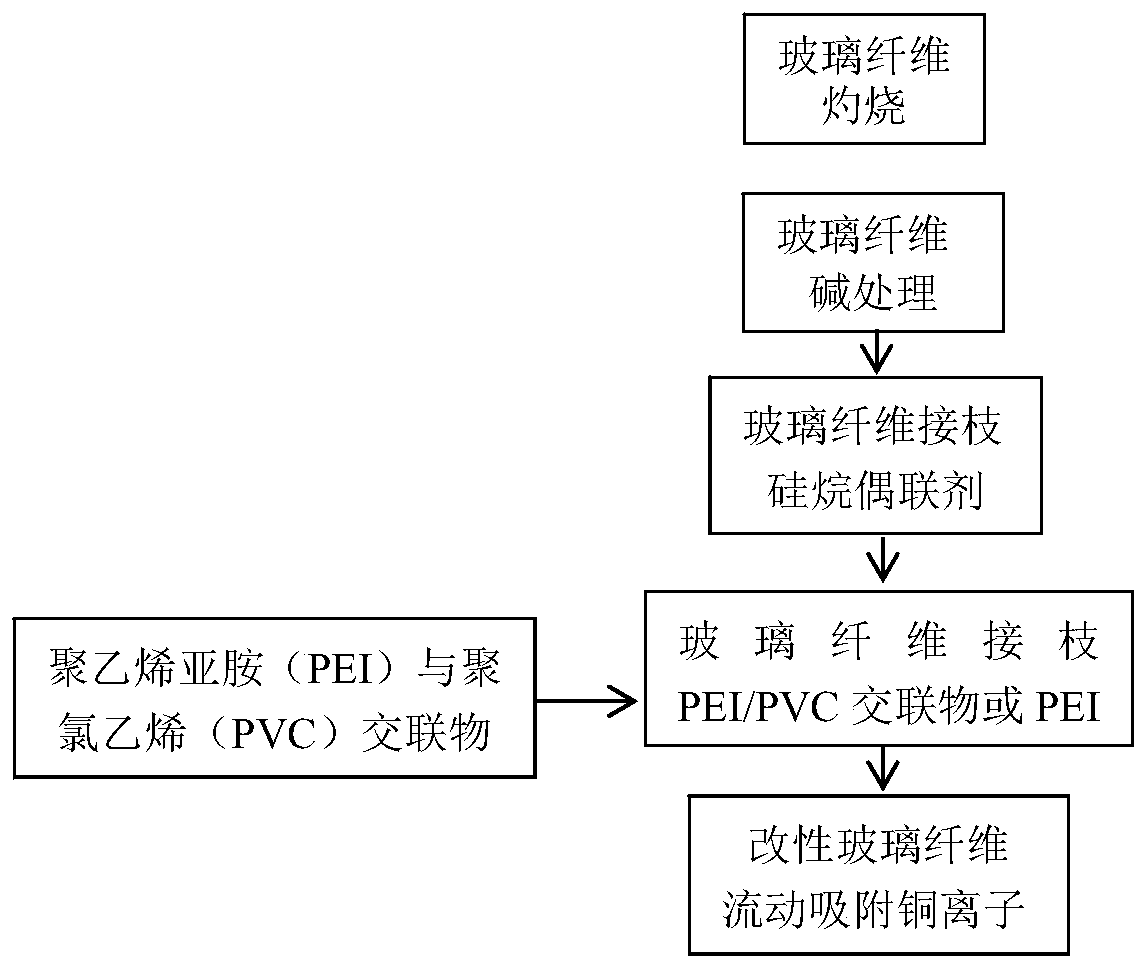

A glass fiber and amination technology, applied in the field of aminated glass fiber and its preparation, can solve the problem of poor copper ion adsorption and regeneration effect, low silanol content on the glass fiber surface, affecting the stability of the graft layer and effect and other problems, to achieve the effect of many connection adsorption sites, short adsorption and elution time, and overcoming poor wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1 glass fiber grafting polyethylenimine

[0038] (1) Alkali treatment

[0039] Considering the diameter of the fluid adsorption fixed bed, the original alkali-free glass fiber is cut into fiber segments whose length is not greater than the diameter of the fluid adsorption fixed bed, immersed in deionized water, and washed in a constant temperature oscillating stirrer at a shaking speed of 80r / min at room temperature Twice, 30min each time, dry the washed glass fiber at 80°C to a constant weight. Then immerse 0.2kg of glass fibers in 5L of 3mol / L sodium hydroxide solution, and heat in a water bath at 80°C for 2 hours in the air where carbon dioxide is removed to obtain alkali-treated glass fibers. Then take out the glass fiber and filter it dry until it does not drip, wash the residual alkali on the surface of the glass fiber with deionized water, and the alkali solution can be reused.

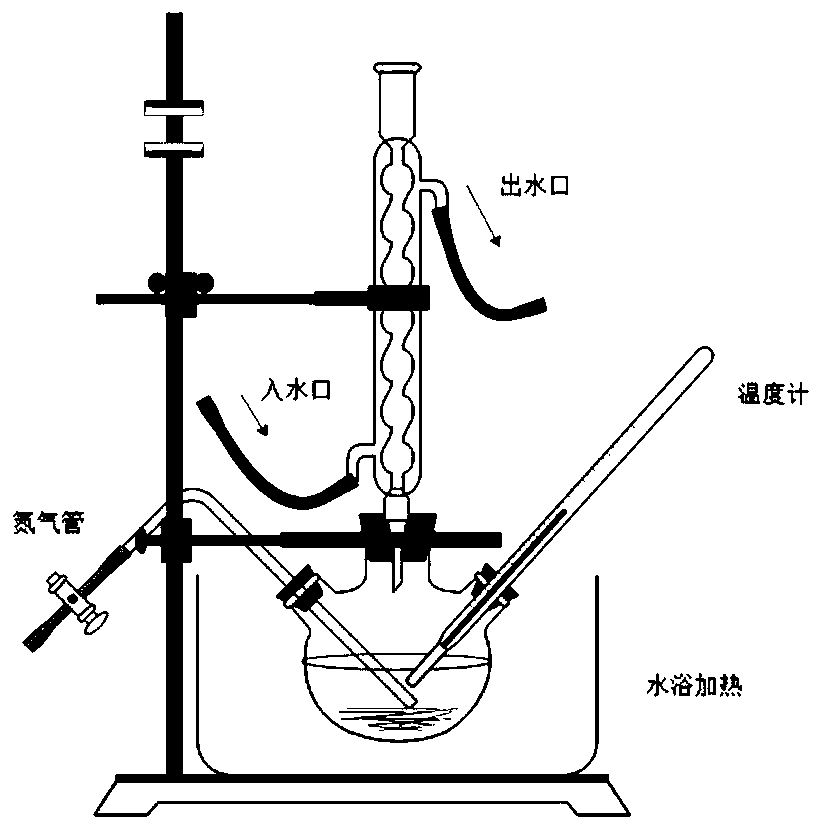

[0040] (2) Glass fiber grafted glycidyl ether oxypropyl trimethoxysilan...

Embodiment 2

[0046] The preparation of embodiment 2 glass fiber graft polyethyleneimine

[0047] (1) Alkali treatment

[0048] Considering the diameter of the fluid adsorption fixed bed, cut the original alkali-free glass fiber into a fiber segment whose length is not greater than the diameter of the fluid adsorption fixed bed, immerse it in deionized water, and stir it at room temperature in a constant temperature oscillating stirrer with a shaking speed of 80r / min Wash twice, 30min each time. The washed glass fibers were dried at 80 °C to constant weight. Soak 0.1kg of glass fibers in 2.5L of 3mol / L sodium hydroxide solution, heat in a water bath at 80°C and stir for 2 hours with air that removes carbon dioxide to obtain alkali-treated glass fibers. Then take out the glass fiber and filter it dry until it does not drip, wash the residual alkali on the surface of the glass fiber with deionized water, and the alkali solution can be reused.

[0049] (2) Glass fiber grafted glycidyl ether...

Embodiment 3

[0053] Embodiment 3 Preparation of cross-linked product of glass fiber grafted polyethyleneimine and polyvinyl chloride

[0054] Present embodiment step (1) and step (2) are with embodiment 1

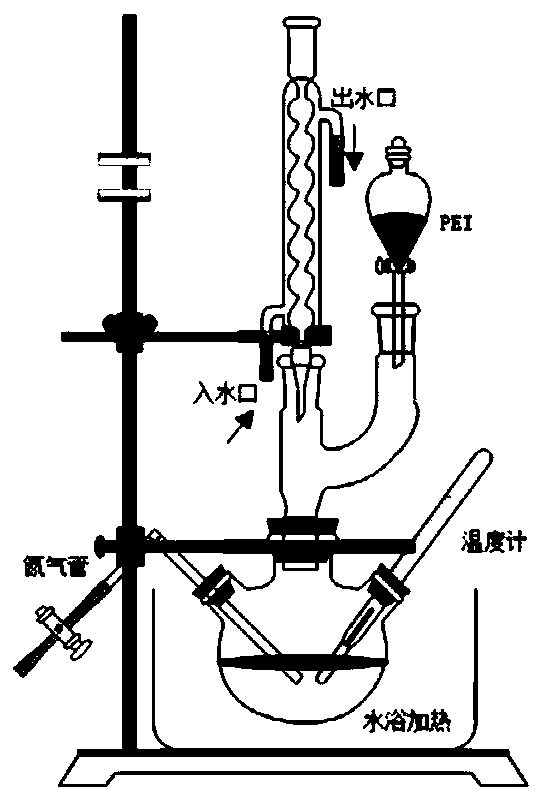

[0055] (3) Preparation of cross-linked products of polyethyleneimine and polyvinyl chloride

[0056] Take 120g of PVC and dissolve it into 0.75L N,N-dimethylacetamide several times in small amounts, then add it to a 2.5L three-neck flask, blow in nitrogen gas for 5min, and heat to 80°C in a water bath. In addition, dissolve 0.36kg PEI into 0.75L N,N-dimethylacetamide, and then place it in a separatory funnel; slowly add PEI solution to PVC solution within 5 minutes, and react for 1 hour until the state of the cross-linked product becomes viscous shape. The crosslinked mixture was transferred to 0.5L deionized water / absolute ethanol (1:1) mixed solvent to precipitate the crosslinked product of polyethyleneimine and polyvinyl chloride. Mix in a shaker for 5 minutes, centrifuge, and dec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com