Silane modified polyether as well as preparation method and application thereof

A silane-modified polyether and polyether technology, applied in polyether adhesives, adhesive types, adhesives, etc., can solve the adverse effects of mechanical properties, sealing properties and weather resistance, sealant preparation and sealant Adverse effects of performance, adverse effects of sealant performance, etc., to achieve excellent sealing effect, stable storage, and stable product performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

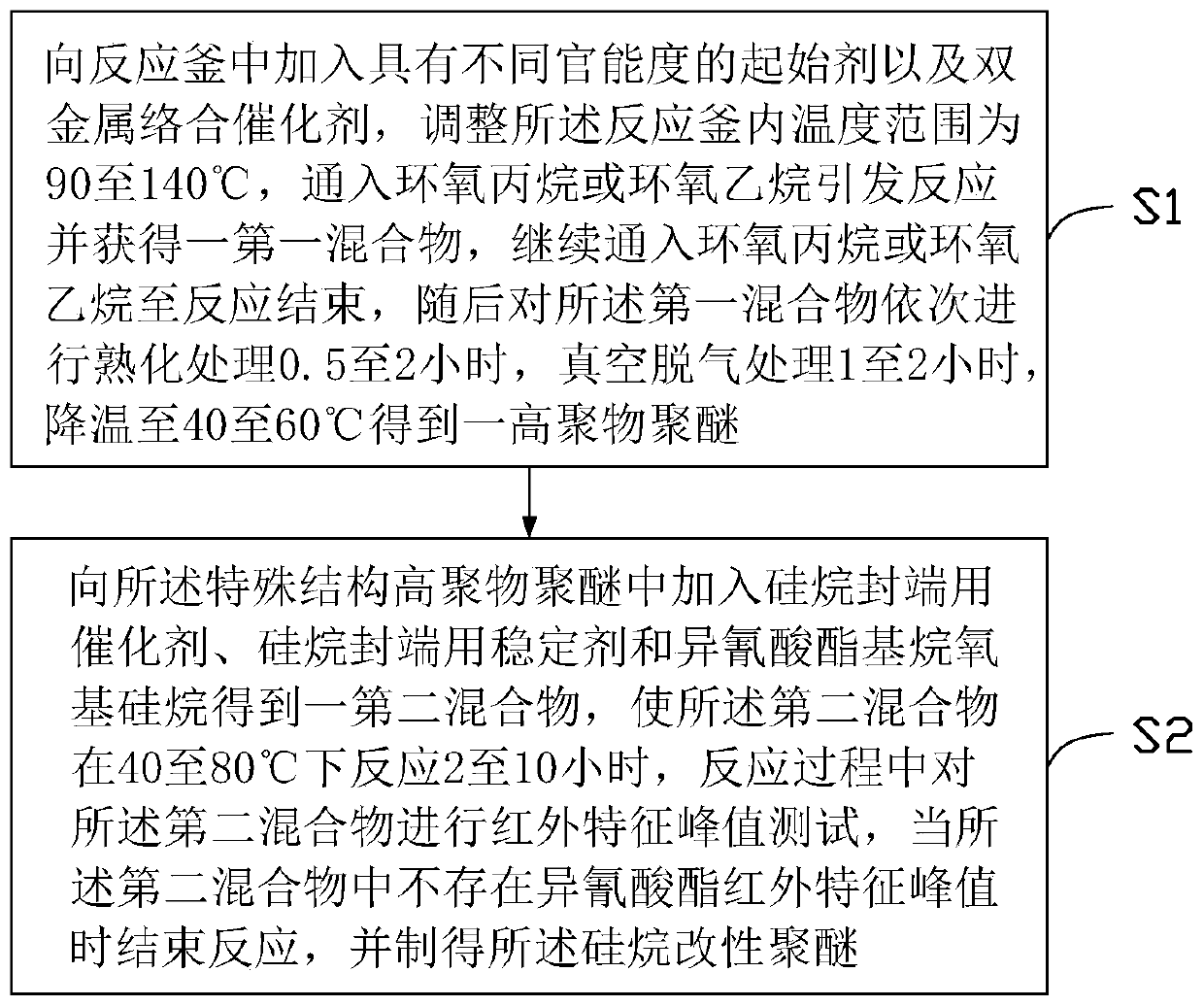

Method used

Image

Examples

Embodiment 1

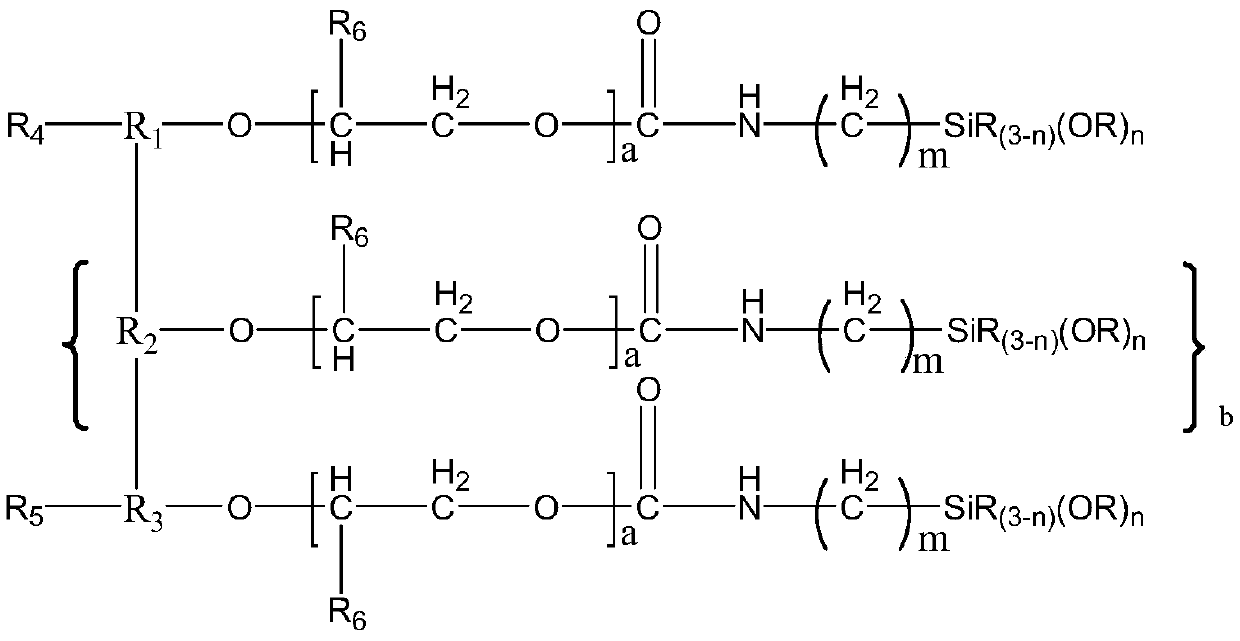

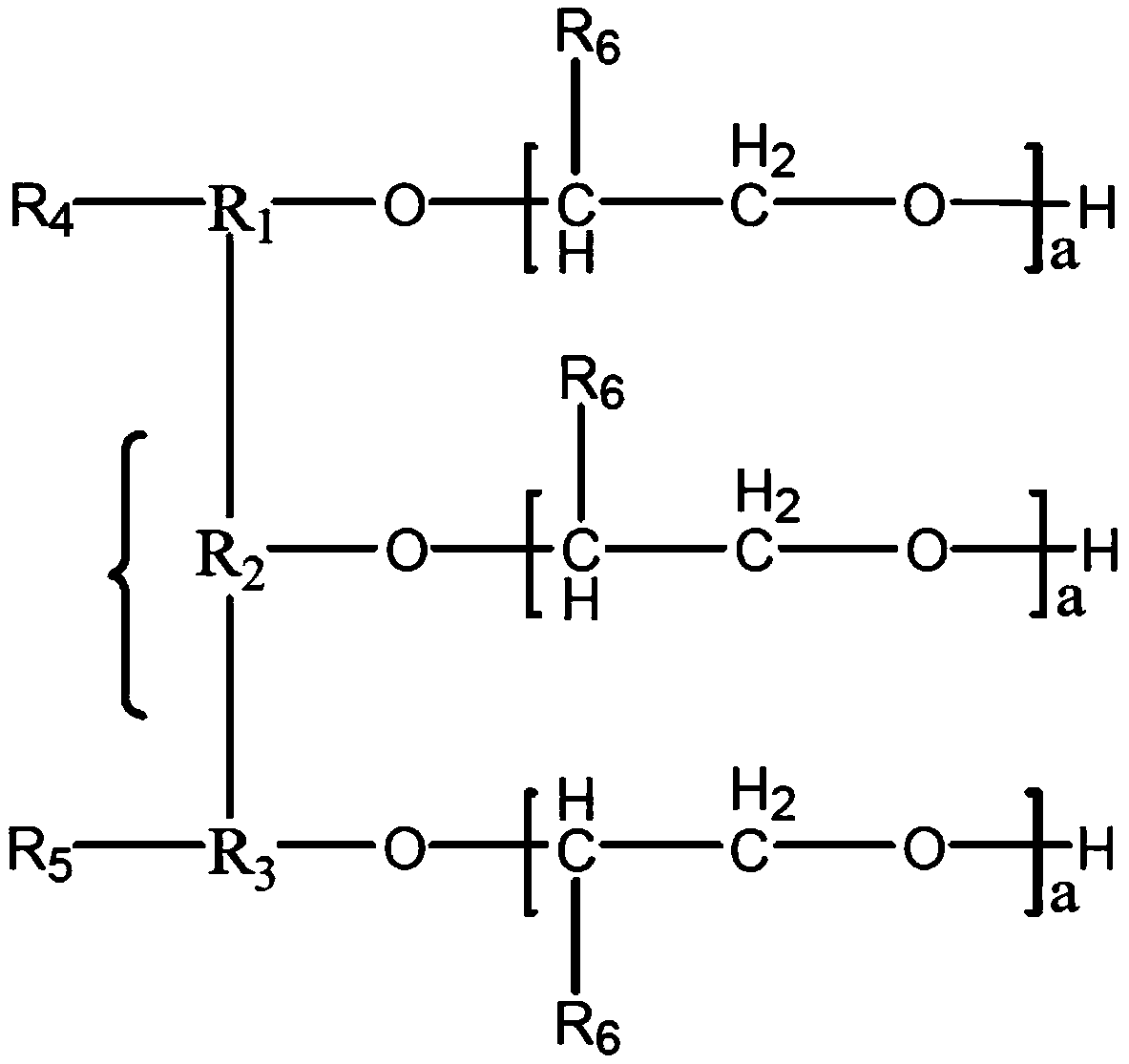

[0047] Add 12.5g propylene glycol ether and 12.5g glycerol ether composite oligomer starter (about 280mgKOH / g) and 0.1g bimetallic complex catalyst that 12.5g propylene glycol ether and 12.5g glycerol ether form in the stainless steel reactor, adjust the temperature range in the reactor 90 to 140° C., feed propylene oxide or ethylene oxide to initiate the reaction and obtain a first mixture.

[0048] Continue to feed 975g of propylene oxide until the reaction is complete, then the first mixture is sequentially aged for 0.5 to 2 hours, vacuum degassed for 1 to 2 hours, and cooled to 40 to 60°C to obtain a polymer with a special structure Polyether (hydroxyl value: 7.02 mgKOH / g).

[0049] Add 0.8g dibutyltin dilaurate, 5g triethylene glycol ether-bis(3-tert-butyl-4-hydroxyl-5-methylphenyl) propionate and 5g three (2,4-di-tert-butyl) phenyl phosphite, further dropwise add 7.5g isocyanate propyl dimethoxysilane and 19.0g isocyanate propyl trimethoxysilane to obtain a second mixtu...

Embodiment 2

[0051] In the stainless steel reactor, add 27.0g1, the composite oligomer initiator (the about 220mgKOH / g of hydroxyl value) and 0.06g bimetallic complex catalyst that 4-butanediol ether and 14.8g glycerol ether are formed, adjust The temperature range in the reaction kettle is 90 to 140° C., and propylene oxide or ethylene oxide is introduced to initiate the reaction and obtain a first mixture.

[0052] Continuously feed 900g of propylene oxide and 60g of ethylene oxide until the reaction is complete, then sequentially perform aging treatment on the first mixture for 0.5 to 2 hours, vacuum degassing treatment for 1 to 2 hours, and cool to 40 to 60°C to obtain a A special structure high polymer polyether (hydroxyl value 9.3mgKOH / g).

[0053] Add 1.2g diheptyltin dilaurate, 10g beta-(3,5-di-tert-butyl-4-hydroxyphenyl) octadecyl propionate to the special structure high polymer polyether, further drop Add 29g isocyanate propyltrimethoxysilane and 8.5g isocyanate propyltriethoxys...

Embodiment 3

[0055] Add 27.0g propylene glycol ether, 1.5g ethylenediamine polyether and 1.5g diethylenetriamine polyether composite oligomer initiator (hydroxyl value about 370mgKOH / g) and 0.1g bimetallic To complex the catalyst, adjust the temperature range in the reactor to 90 to 140° C., feed propylene oxide or ethylene oxide to initiate the reaction and obtain a first mixture.

[0056] Continue to feed 890g of propylene oxide and 80g of ethylene oxide until the reaction is complete, then sequentially perform aging treatment on the first mixture for 0.5 to 2 hours, vacuum degassing treatment for 1 to 2 hours, and cool to 40 to 60°C to obtain a A special structure high polymer polyether (hydroxyl value 11.2mgKOH / g).

[0057] Add 1.5g zinc octadecanoate, 5g beta-(3,5-di-tert-butyl-4-hydroxyphenyl) octadecyl propionate and 0.1g sodium hypophosphite in the special structure polymer polyether , further drop 4g isocyanate methyl dimethoxysilane, 35g isocyanate propyl trimethoxysilane and 5....

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com