Rare-earth modified aqueous alkyd resin antibacterial luminescent coating material

A water-based alkyd resin and rare earth modification technology, which is applied in luminescent coatings, antifouling/underwater coatings, polyester coatings, etc., can solve the problems of uneven dispersion of additive coatings, unsustainable effects, and environmental pollution, and achieve Long luminous duration, long-lasting antibacterial performance, and good aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

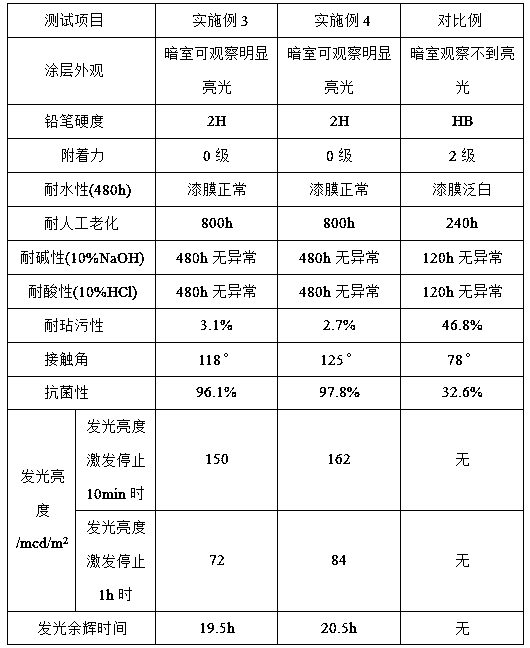

Examples

Embodiment 1

[0035] A rare earth modified water-based alkyd resin X, the steps are as follows:

[0036] a) In the multifunctional reaction kettle, add 8.5 parts of dehydrated linseed oil, 7.8 parts of maleic anhydride, 2.2 parts of 1,4-butanediol, 5.8 parts of trimethylolpropane, dimethylol 1.8 parts of propionic acid and 8.0 parts of xylene, N 2 , to remove the O in the reactor 2 ;

[0037] b) Heat up to 105-110°C to reflux, keep it warm for 0.5h, remove part of the water, quickly raise the temperature to 150-160°C, stir fully until the material is dissolved, then stir and keep warm at a speed of 200-400 r / min for 1h , then heat up to 180°C at a speed of 20°C / h for 1 hour, add 1.4 parts of benzoic acid, continue to heat for 1 to 1.5 hours, heat up to 210 to 220°C at a speed of 20°C / h, and heat for 3.0 to 3.5 hours , until the measured acid value is consistent with the design value, the water produced by the reaction is separated by a water separator;

[0038]c) Cool down to 160°C at a...

Embodiment 2

[0041] A rare earth modified water-based alkyd resin Y, the steps are as follows:

[0042] a) In the multifunctional reaction kettle, add 9.5 parts of dehydrated soybean oil, 2.8 parts of acetic anhydride, 7.2 parts of adipic acid, 3.2 parts of neopentyl glycol, 5.3 parts of pentaerythritol, and dimethylol propane in order according to the weight of the formula. 1.6 parts of acid and 9.0 parts of xylene, N 2 , to remove the O in the reactor 2 ;

[0043] b) Heat up to 105-110°C to reflux, keep it warm for 0.5h, remove part of the water, quickly raise the temperature to 150-160°C, stir fully until the material is dissolved, then stir and keep warm at a speed of 200-400 r / min for 1h , then heat up to 180°C at a speed of 20°C / h for 1 hour, add 1.5 parts of benzoic acid, continue to heat for 1 to 1.5 hours, heat up to 210 to 220°C at a speed of 20°C / h, and heat for 3.0 to 3.5 hours , until the measured acid value is consistent with the design value, the water produced by the rea...

Embodiment 3

[0047] A rare earth modified water-based alkyd resin antibacterial luminous coating, which consists of: 40.0 parts of rare earth modified water-based alkyd resin X, 18.0 parts of fluorine-modified water-based alkyd resin, 4.5 parts of diatomaceous earth, titanium 5.5 parts of white powder, 3.5 parts of solid glass beads, 0.3 parts of leveling agent, 0.5 parts of wetting agent, 0.8 parts of dispersing agent, 0.6 parts of defoaming agent, 0.3 parts of anti-settling rheological agent, 2.5 parts of pH regulator, film forming 4.0 parts of additives, 19.5 parts of deionized water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com