Anti-reflection film coating liquid applicable to anti-dazzle patterned solar glass, preparation method of anti-reflection film coating liquid and method for manufacturing solar glass with same

A solar glass and anti-glare technology, which can be used in biocide-containing paints, antifouling/underwater coatings, and devices for coating liquids on surfaces, etc. The light rate and dirt resistance are not ideal, and it is difficult to achieve anti-glare and other problems, so as to achieve the effect of no defects on the film surface, improved functionality and power generation, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

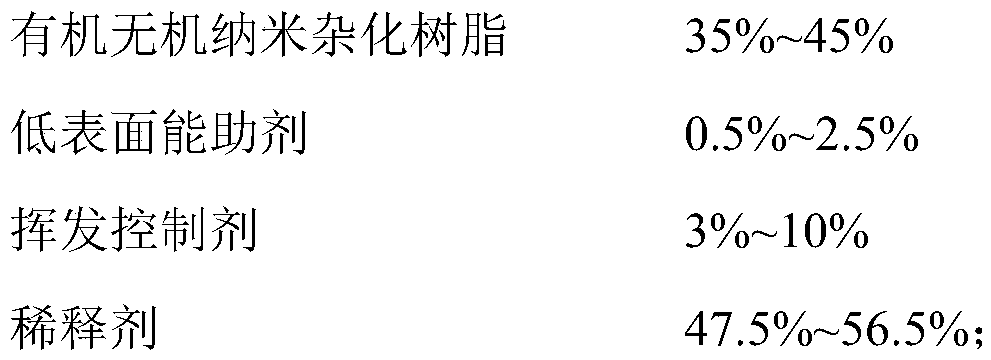

[0051] A kind of anti-reflective coating liquid suitable for anti-glare pattern solar glass, it comprises the raw material of following weight percent:

[0052]

[0053] Wherein, the organic-inorganic nano-hybrid resin comprises the following raw materials in weight percent:

[0054]

[0055] Wherein, the low surface energy additive is one or any combination of two or more of hydroxyl silicone oil, water-soluble silicone oil, hydrogen-containing silicone oil, polyether modified silicone oil or DC-57;

[0056] Wherein, the volatilization control agent is one or any combination of two or more of N, N dimethylformamide, acetylacetone or environment-friendly mixed dibasic acid ester;

[0057] Among them, the diluent is methanol, ethanol, isopropanol, n-butanol, ethylene glycol methyl ether, ethylene glycol monobutyl ether, propylene glycol methyl ether, propylene glycol butyl ether, diethylene glycol methyl ether, diethylene glycol monobutyl ether One or any combination of ...

Embodiment 2

[0068] A kind of anti-reflective coating liquid suitable for anti-glare pattern solar glass, it comprises the raw material of following weight percent:

[0069]

[0070] Wherein, the organic-inorganic nano-hybrid resin comprises the following raw materials in weight percent:

[0071]

[0072] Among them, the low surface energy additive is hydroxyl silicone oil;

[0073] Wherein, the volatilization control agent is N, N dimethylformamide;

[0074] Wherein, the diluent is methanol.

[0075] Wherein, solvent is ethanol;

[0076] Wherein, the organosilicon modified resin is organosilicon modified polyester resin;

[0077] Wherein, silicate is tetraethoxysilane;

[0078] Wherein, the catalyst is hydrochloric acid.

[0079] Above-mentioned a kind of preparation method that is applicable to the antireflection coating solution of anti-glare pattern solar glass, it comprises the following steps:

[0080] Step 1. Preparation of organic-inorganic nano-hybrid resin: add the fo...

Embodiment 3

[0084] A kind of anti-reflective coating liquid suitable for anti-glare pattern solar glass, it comprises the raw material of following weight percent:

[0085]

[0086] Wherein, the organic-inorganic nano-hybrid resin comprises the following raw materials in weight percent:

[0087]

[0088] Wherein, the low surface energy additive is a composition of water-soluble silicone oil and hydrogen-containing silicone oil;

[0089] Wherein, the volatilization control agent is a composition of acetylacetone and an environment-friendly mixed dibasic acid ester;

[0090] Wherein, the diluent is a combination of ethanol, isopropanol and n-butanol.

[0091] Wherein, solvent is the composition of isopropanol, n-butanol and ethylene glycol methyl ether;

[0092] Wherein, the organosilicon-modified resin is a composition of organosilicon-modified alkyd resin and organosilicon-modified acrylic resin;

[0093] Wherein, silicate is the composition of tetramethoxysilane and vinyltrietho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com