A semiconductor heterojunction gas-sensing material and its preparation method and application

A gas-sensing material and heterojunction technology, which is applied in the analysis of materials, material analysis by electromagnetic means, instruments, etc., can solve the problems of insufficient uniformity of semiconductor recombination, long synthesis cycle, high working temperature, etc., to improve sensitivity and response recovery The effect of time, high sensitivity, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

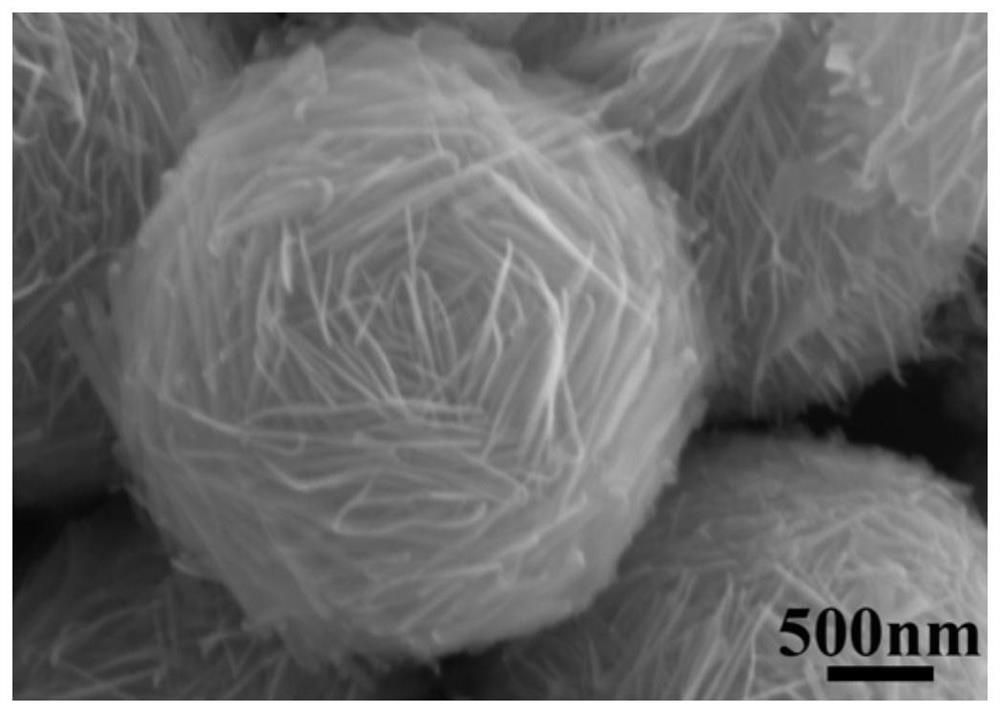

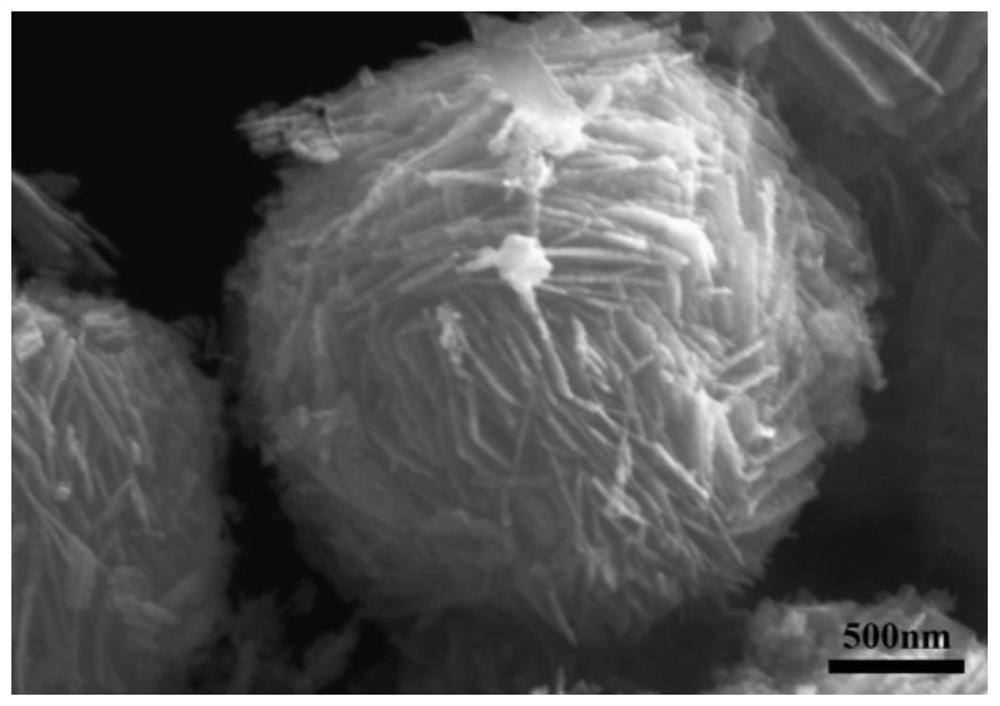

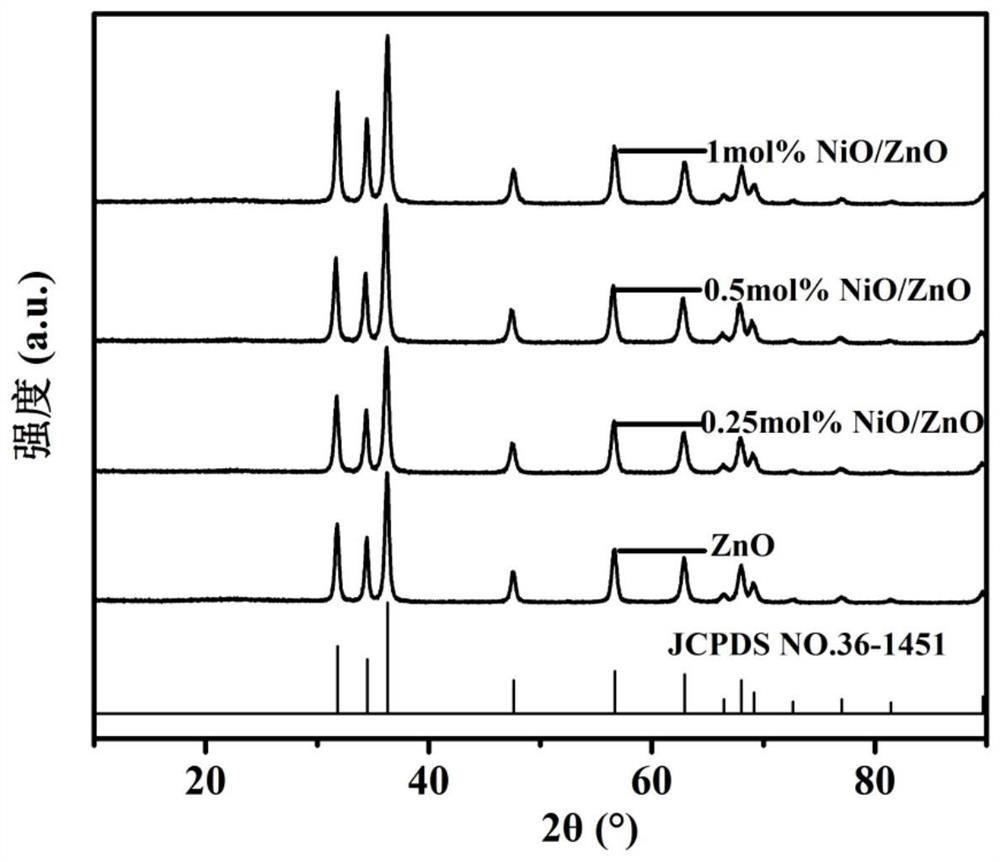

[0044] A zinc oxide nickel oxide porous microsphere gas sensing material, the gas sensing material is a lamellar microsphere with a diameter of 2 μm and a specific surface area of 20.9 m 2 g -1 -23.9m 2 g -1 ,like Figure 4 shown.

[0045] With zinc acetate dihydrate Zn(CH 3 COO) 2 . 2H 2 O, nickel acetate tetrahydrate Ni(CH 3 COO) 2 . 4H 2 O as the raw material, polyvinylpyrrolidone (PVP-K30) as the surfactant and as the dispersant, deionized water as the solvent, the mass ratio of the metal salt (zinc salt and nickel salt) and the surfactant is 1:1.25, until the salt is dissolved Then, 0.19 g of ammonium carbonate was added, and the reaction was carried out at 180° C. for 2 hours. The product was washed and dried to obtain a precursor of zinc oxide and nickel oxide. The obtained precursor was kept at 450° C. for two hours and calcined to obtain a zinc oxide nickel oxide microsphere gas-sensing material. The molar percentage of nickel oxide was 0.5%.

[0046] ...

Embodiment 2

[0050] A zinc oxide nickel oxide porous microsphere gas sensing material, the gas sensing material is a lamellar microsphere with a diameter of 2 μm and a specific surface area of 20.9 m 2 g -1 -23.9m 2 g -1 .

[0051] With zinc acetate dihydrate Zn(CH 3 COO) 2 . 2H 2 O, nickel acetate tetrahydrate Ni(CH 3 COO) 2 . 4H 2 O as a raw material, polyvinylpyrrolidone (PVP-K30) as a surfactant and as a dispersant, deionized water as a solvent, the mass ratio of the metal salt and the surfactant is 1:1, and 0.1 g of ammonium carbonate is added after the salt is dissolved, The reaction was carried out at 150° C. for 1.8 hours, and the product was washed and dried to obtain a zinc oxide nickel oxide precursor. The obtained precursor was calcined at 400° C. for two hours to obtain a zinc oxide nickel oxide microsphere gas-sensing material. The molar percentage of nickel oxide was 1%.

[0052] A gas sensor was prepared with the zinc oxide nickel oxide composite material of ...

Embodiment 3

[0057] Compared with Example 1, a zinc oxide nickel oxide porous microsphere gas-sensing material, the gas-sensing material is a lamellar microsphere with a diameter of 2 μm and a specific surface of 20.9 m 2 g -1 -23.9m 2 g -1 .

[0058] With zinc acetate dihydrate Zn(CH 3 COO) 2 . 2H 2 O, nickel acetate tetrahydrate Ni(CH 3 COO) 2 . 4H 2 O as raw material, polyvinylpyrrolidone (PVP-K30) as surfactant and as dispersant, deionized water as solvent, the mass ratio of metal salt and surfactant is 1:1.5, after the salt is dissolved, 0.23g of ammonium carbonate is added, The reaction was carried out at 200° C. for 2.2 hours, and the product was washed and dried to obtain a zinc oxide nickel oxide precursor. The obtained precursor was calcined at 500° C. for two and a half hours to obtain a zinc oxide nickel oxide microsphere gas-sensing material. The molar percentage of nickel oxide was 0.25%.

[0059] The composite metal oxide gas-sensing material prepared in Example...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com