Preparation method and application of manganese dioxide/polyoxyethylene composite solid electrolyte

A technology of polyethylene oxide and solid electrolyte, applied in solid electrolyte, non-aqueous electrolyte, non-aqueous electrolyte battery, etc., to achieve good electrochemical stability, low price, and avoid drying up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

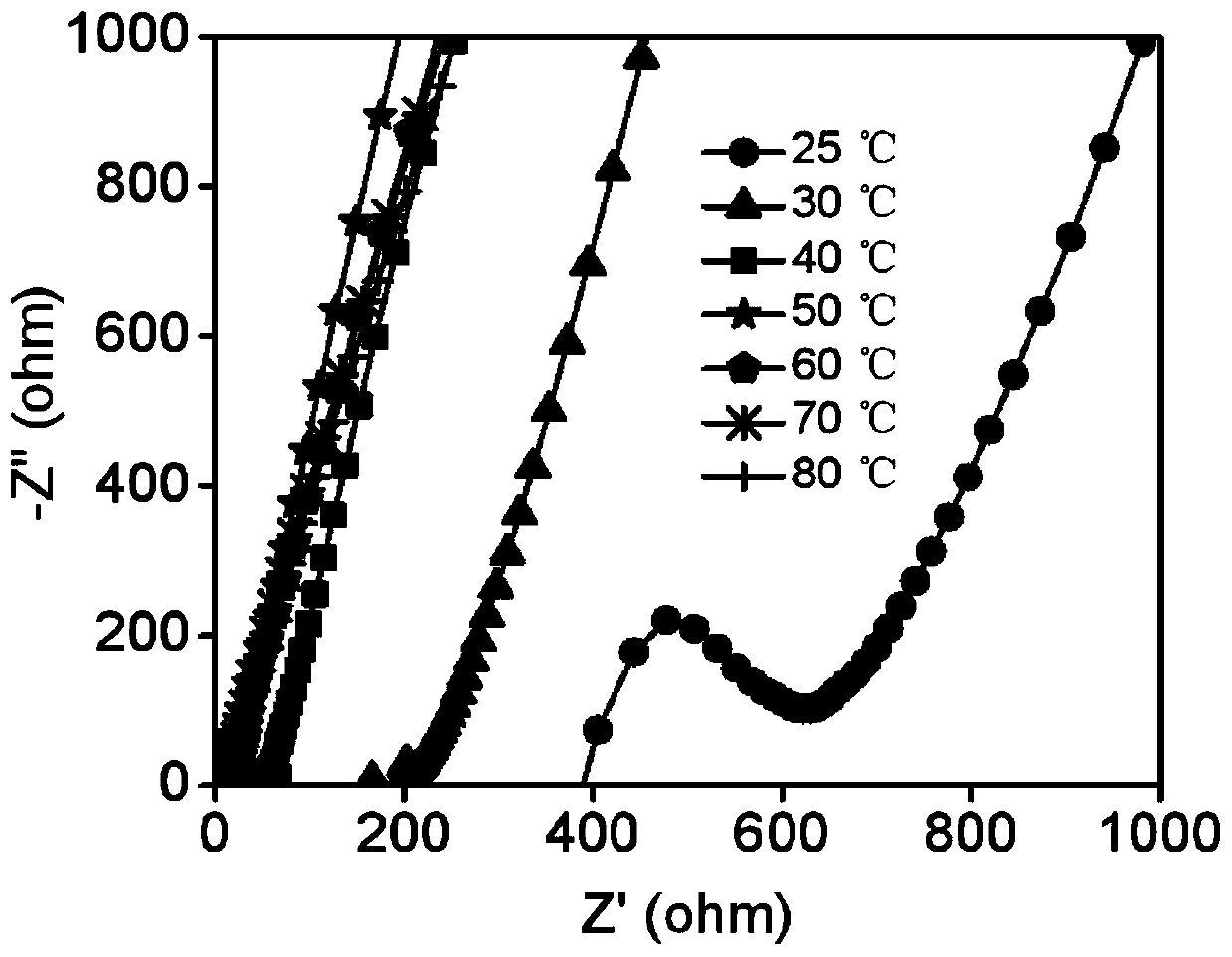

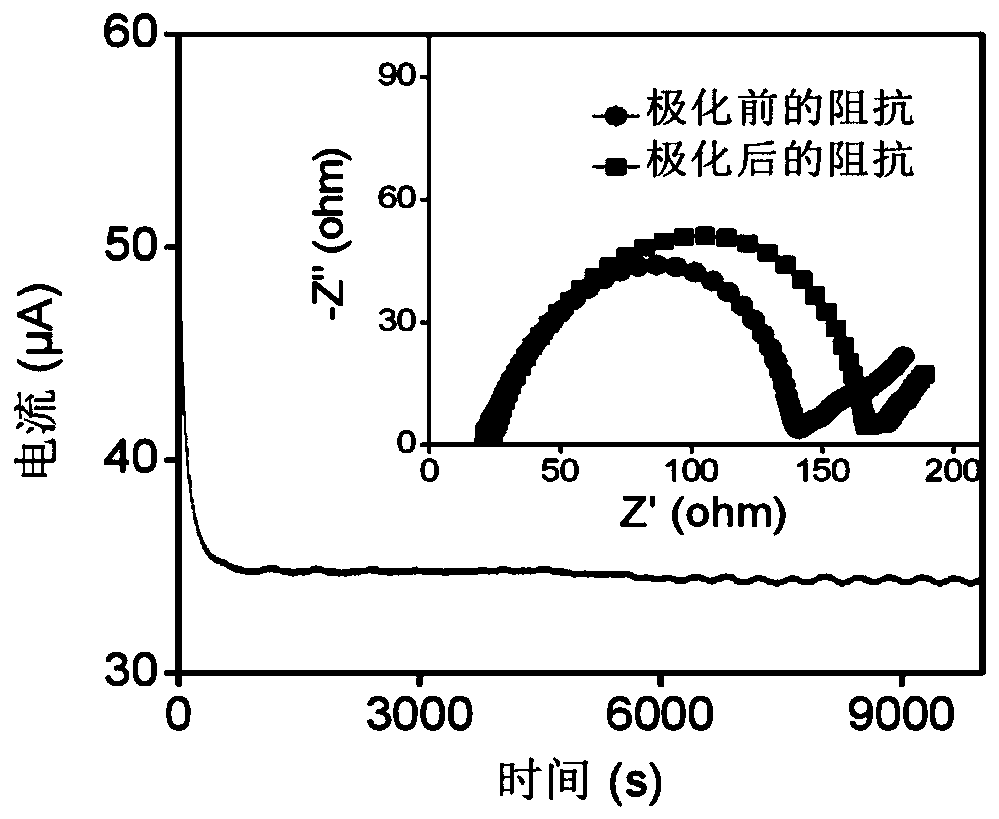

[0027] Embodiment one, the preparation method of the present embodiment comprises the following steps:

[0028] (1), put 0.5g of manganese dioxide nanosheets into a 500mL round-bottomed flask, add 200mL of acetonitrile to it, put it into an ultrasonic cleaner with a power of 40W, and perform ultrasonication for 6 hours to obtain manganese dioxide-acetonitrile For the dispersion liquid, add 10g of polyethylene oxide (abbreviation: PEO) into the dispersion liquid, and magnetically stir for 1 hour to form a uniformly mixed emulsion; the manganese dioxide nanosheets are nanosheets with a diameter of 20-1000nm and a thickness of 2-100nm;

[0029] (2) Add 1.6 g of lithium bistrifluoromethanesulfonimide (abbreviation: LiTFSI) to the mixed emulsion in step 1, and stir with a magnetic stirrer for 1 hour to obtain a mixed solution;

[0030] (3) Slowly pour the mixed solution prepared in step 2 into a polytetrafluoroethylene mold, place it in a fume hood, and wait for the acetonitrile to...

Embodiment 2

[0036] Embodiment two, the preparation method of the present embodiment comprises the following steps:

[0037] (1), put 0.1g of nano-manganese dioxide into a 500mL round bottom flask, add 300mL of acetonitrile into it, put it into an ultrasonic cleaner with a power of 40W, and perform ultrasonication for 1 hour to obtain a manganese dioxide-acetonitrile dispersion Liquid, add 10g polyethylene oxide (referred to as: PEO) to the dispersion liquid, magnetically stir for 1 hour to form a uniform emulsion; manganese dioxide nanosheets are nanosheets with a diameter of 20-1000nm and a thickness of 2-100nm;

[0038] (2) Add 0.5 g of lithium bistrifluoromethanesulfonimide (abbreviation: LiTFSI) to the mixed emulsion in step 1, and stir with a magnetic stirrer for 1 hour to obtain a mixed solution;

[0039] (3) Slowly pour the mixed solution prepared in step 2 into a polytetrafluoroethylene mold, place it in a fume hood, and wait for the acetonitrile to evaporate to form a polymer sol...

Embodiment 3

[0042] Embodiment three, the preparation method of the present embodiment comprises the following steps:

[0043] (1), put 0.7g of manganese dioxide nanosheets into a 500mL round-bottomed flask, add 250mL of methanol thereinto, put it into an ultrasonic cleaner, and use a power of 40W to perform ultrasonication for 3 hours to obtain manganese dioxide-acetonitrile Dispersion liquid, add 10g polyethylene oxide (referred to as: PEO) to the dispersion liquid, magnetically stir for 1 hour to form a uniformly mixed emulsion;

[0044] (2) Add 2.5 g of lithium bistrifluoromethanesulfonimide (abbreviation: LiTFSI) to the mixed emulsion in step 1, and stir with a magnetic stirrer for 1 hour to obtain a mixed solution;

[0045] (3) Slowly pour the mixed solution prepared in step 2 into a polytetrafluoroethylene mold, place it in a fume hood, and wait for the methanol to evaporate to form a polymer solid electrolyte membrane. Place it in a vacuum drying oven, and dry it in vacuum at 80°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com