Modified bamboo fiber enhanced chitosan-based porous material and preparation method thereof

A technology of porous materials and bamboo fibers, which is applied in the fields of medical science, prosthesis, tissue regeneration, etc., can solve the problems of unreported research on porous materials, and achieve the effect of being suitable for large-scale production, low cost and wide source.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

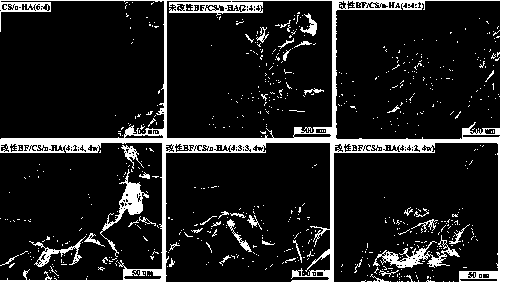

[0016] Example 1: Take 5.0 g of chitosan (90% degree of deacetylation, molecular weight of 200,000), add 200 ml of deionized water, and then add 4.0 g of modified bamboo fibers with a length of 1 mm and a diameter of 0.2 mm, At the same time, 1.0 g of nano-hydroxyapatite ultrasonically dispersed in 100 ml of water was added dropwise to the above-mentioned bamboo fiber / chitosan mixture. After continuing ultrasonic magnetic stirring for 4 hours, 6 ml of glacial acetic acid was added to obtain the bamboo fiber / nano-hydroxyapatite / chitosan ternary composite gel. Freeze in a -20°C freezer for 48 hours. Freeze-dry to constant weight with a freeze dryer. Then it was soaked in 10% NaOH solution for 30 minutes, washed until neutral, and dried. Cut it into a block material of 10 mm×10 mm×10 mm, the measured compressive strength is about 1.5 MPa, the porosity is 82%, and the average pore diameter is 250 um; soaked in simulated body fluid in vitro for 4 weeks, there are a lot of The bo...

Embodiment 2

[0017] Embodiment 2: Take by weighing 4.0 g chitosan (deacetylation degree 95%, molecular weight is 300,000), add 200 ml deionized water, then add 3.0 g length is 1 mm, diameter is 0.2 mm modified bamboo fiber, At the same time, 3.0 g of bioactive glass ultrasonically dispersed in 100 ml of water was added dropwise to the above-mentioned bamboo fiber / chitosan mixture. After continuing ultrasonic magnetic stirring for 4 h, 6 ml of glacial acetic acid was added to obtain the bamboo fiber / bioactive glass / chitosan ternary composite gel. Place in a -20°C freezer for 48 hours. Freeze-dry to constant weight with a freeze dryer. Then it was soaked in 5% NaOH solution for 30 minutes, washed until neutral, and dried. Cut it into a block material of 10 mm×10 mm×10 mm, the measured compressive strength is about 2.2 MPa, the porosity is 75%, and the average pore diameter is 200 um; soaked in simulated body fluid in vitro for 4 weeks, there are a lot of The bone-like apatite is deposited...

Embodiment 3

[0018] Embodiment 3: Weigh 3.0 g chitosan (deacetylation degree 90%, molecular weight is 250,000), add 300 ml deionized water, then add 5.0 g length is 1 mm, diameter is 0.2 mm modified bamboo fiber, At the same time, 2.0 g of calcium phosphate ultrasonically dispersed in 100 ml of water was added dropwise to the above-mentioned bamboo fiber / chitosan mixture. After continuing ultrasonic magnetic stirring for 4 hours, 8 ml of glacial acetic acid was added to obtain the bamboo fiber / calcium phosphate / chitosan ternary composite gel. Place in a -20°C freezer for 48 hours. Freeze-dry to constant weight with a freeze dryer. Then it was soaked in 8% NaOH solution for 30 minutes, washed until neutral, and dried. Cut it into a block material of 10 mm×10 mm×10 mm, the measured compressive strength is about 2.0 MPa, the porosity is 78%, and the average pore diameter is 200 um; soaked in simulated body fluid in vitro for 4 weeks, there are a lot of Bone-like apatite deposition, the com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com