Gasification device for producing synthesis gas from high-moisture organic material

A technology of organic materials and gasification device, which is applied in the direction of gasification process, combination of fuel pre-dry distillation, and production of combustible gas, etc., can solve the problems of waste of biomass drying water vapor sensible heat, low combustion efficiency of pyrolysis carbon, etc., and save energy. Energy consumption, avoid aging, improve the effect of economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The dehydrated sludge obtained after sewage treatment in a sewage treatment plant has a moisture content of 54% after being filtered by a heating plate and frame. In order to avoid the cost of large energy consumption, equipment investment and odor control caused by re-drying, there is no The traditional method of incineration after drying is adopted, but the gasification device that uses the high-humidity organic material provided by the present invention to produce syngas is used to recycle it, and a better quality gas product is obtained through heat treatment.

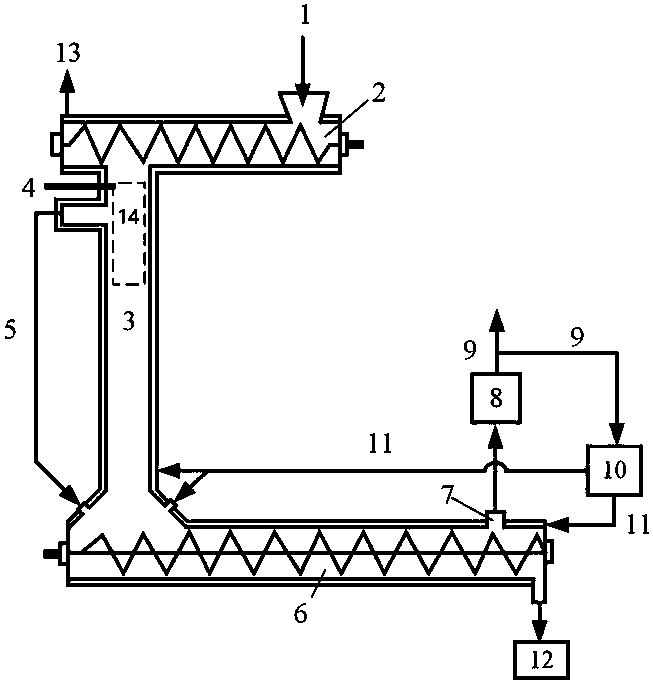

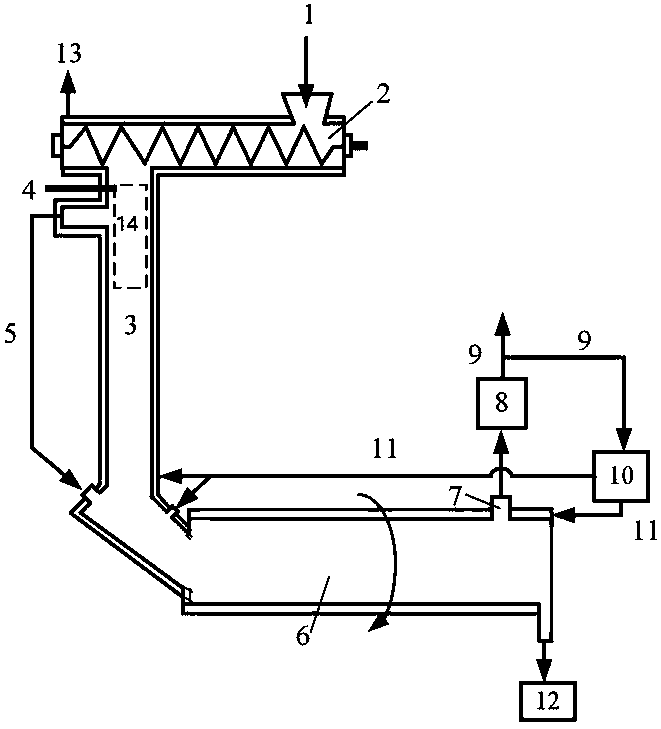

[0024] figure 1 It is a schematic structural diagram of a gasification device for high-humidity organic materials in Examples 1-3 of the present invention.

[0025] Such as figure 1 As shown, the gasification device for producing syngas from high-humidity organic materials provided in this embodiment includes a screw feed device 2, a pyrolysis reactor 3, a disturbance device interface 4, an insulated delive...

Embodiment 2

[0048] The chicken manure produced by a chicken factory has a moisture content of 70% and high N content, and the fermentation biogas production system is unstable, so it was changed to a pyrolysis gasification gas production scheme. The straw is blended according to the ratio of 30%, the final moisture is 53.5%, and the low calorific value of the dry basis is 11.55MJ / kg. The user wishes to use it as heating gas after gasification.

[0049] figure 1 It is a structural schematic diagram of a gasification device for generating syngas from high-humidity organic materials in Examples 1-3 of the present invention.

[0050] Such as figure 1 As shown, the gasification device for producing syngas from high-humidity organic materials provided in this embodiment includes a screw feed device 2, a pyrolysis reactor 3, a disturbance device interface 4, an insulated delivery pipe 5 for water vapor and volatile matter mixture, Gasification reactor 6 , solid particle separator 7 , gas puri...

Embodiment 3

[0067] The biogas residue produced by an anaerobic fermentation plant has a moisture content of 49% after preliminary dehydration and drying, and a low calorific value of 11.2MJ / kg on a dry basis. The user wishes to realize the disposal of biogas residue and recover energy from it, so the device provided by the invention is used for gasification.

[0068] figure 1 It is a structural schematic diagram of a gasification device for generating syngas from high-humidity organic materials in Examples 1-3 of the present invention.

[0069] Such as figure 1 As shown, the gasification device for producing syngas from high-humidity organic materials provided in this embodiment includes a screw feed device 2, a pyrolysis reactor 3, a disturbance device interface 4, an insulated delivery pipe 5 for water vapor and volatile matter mixture, Gasification reactor 6 , solid particle separator 7 , gas purification device 8 , combustion device 10 , high-temperature flue gas pipeline 11 , resid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Moisture content | aaaaa | aaaaa |

| Moisture content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com