A kind of silicone gel curing agent for preparing heat insulation material and preparation method thereof

A technology of heat insulating material and silica gel, applied in the directions of silicon oxide, silicon dioxide, etc., can solve the problems of complicated preparation method and practical impact, and achieve the effects of simple preparation method, elimination of gas-liquid dispersion, and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

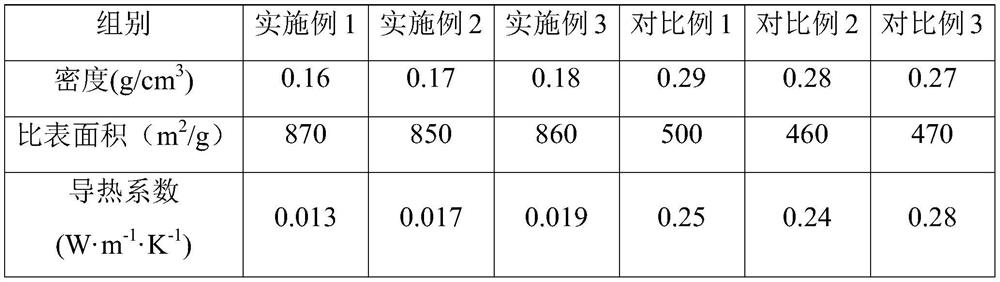

Examples

Embodiment 1

[0028] Embodiment 1 A kind of silicone gel curing agent for preparing thermal insulation material

[0029] The silicone gel curing agent used to prepare heat insulation materials consists of the following components and parts by weight: 20 parts of silicon-based framework material, 0.1 part of filler, 3 parts of initiator, 25 parts of sodium bicarbonate, 4 parts of sodium lauryl sulfate and 48 parts of water.

[0030] The silicon-based skeleton material is composed of methanol silane triol, epoxy silane and amino silane in a weight ratio of 1:4:3.

[0031] The filler is composed of hydroxyapatite and aluminum chloride in a weight ratio of 3:7.

[0032] The initiator is composed of sodium persulfate and dimethylaniline in a weight ratio of 1:1:1.

[0033] The preparation method of the silicone gel curing agent used to prepare heat insulating materials comprises the following steps:

[0034] Mix the silicon-based framework material, filler, initiator, sodium bicarbonate, sod...

Embodiment 2

[0035] Embodiment 2 A kind of silicone gel curing agent for preparing thermal insulation material

[0036] The silicone gel curing agent used to prepare heat insulation materials is composed of the following components and parts by weight: 2.5 parts of silicon-based skeleton material, 0.1 part of filler, 1 part of initiator, 12 parts of ammonia water, 12 parts 1 part of sodium alkylsulfonate and 30 parts of water.

[0037] The silicon-based skeleton material is composed of potassium triethylsiliconate and potassium butyldimethylsiliconate in a weight ratio of 1:4.

[0038] The filler is composed of aluminum hydrate, potassium chloride and aqueous titanium dioxide in a weight ratio of 1:5:3.

[0039] The initiator is composed of methyllithium and magnesium peroxide in a weight ratio of 1:1.

[0040] The preparation method of the silicone gel curing agent used to prepare heat insulating materials comprises the following steps:

[0041]Mix the silicon-based framework materia...

Embodiment 3

[0042] Embodiment 3 A kind of silicone gel curing agent for preparing thermal insulation material

[0043] The silicone gel curing agent used to prepare heat insulation materials consists of the following components and parts by weight: 30 parts of potassium triethylsiliconate, 0.2 parts of calcium chloride, 4 parts of methyl zinc chloride, Potassium hydroxide 30 parts, Span 206 parts and ethanol 62 parts.

[0044] The preparation method of the silicone gel curing agent used to prepare heat insulating materials comprises the following steps:

[0045] Mix potassium triethylsiliconate, calcium chloride, methyl zinc chloride, potassium hydroxide and ethanol in a reaction kettle, set the temperature at 350°C, and the pressure at 2.0Mpa, react for 5 hours, dilute with water, and filter. After the filtrate was allowed to stand for 24 hours, add a corresponding amount of Span 20, stir and filter to obtain the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com