Self-aggregation granular sludge construction method for cascade energy recovery of wastewater

A technology for granular sludge and energy recovery, applied in microorganism-based methods, biochemical equipment and methods, bioreactors/fermenters for specific purposes, etc. , long start-up time and other problems, to achieve the effect of rapid continuous and stable hydrogen production, shorten start-up time, and reduce hydrogen production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

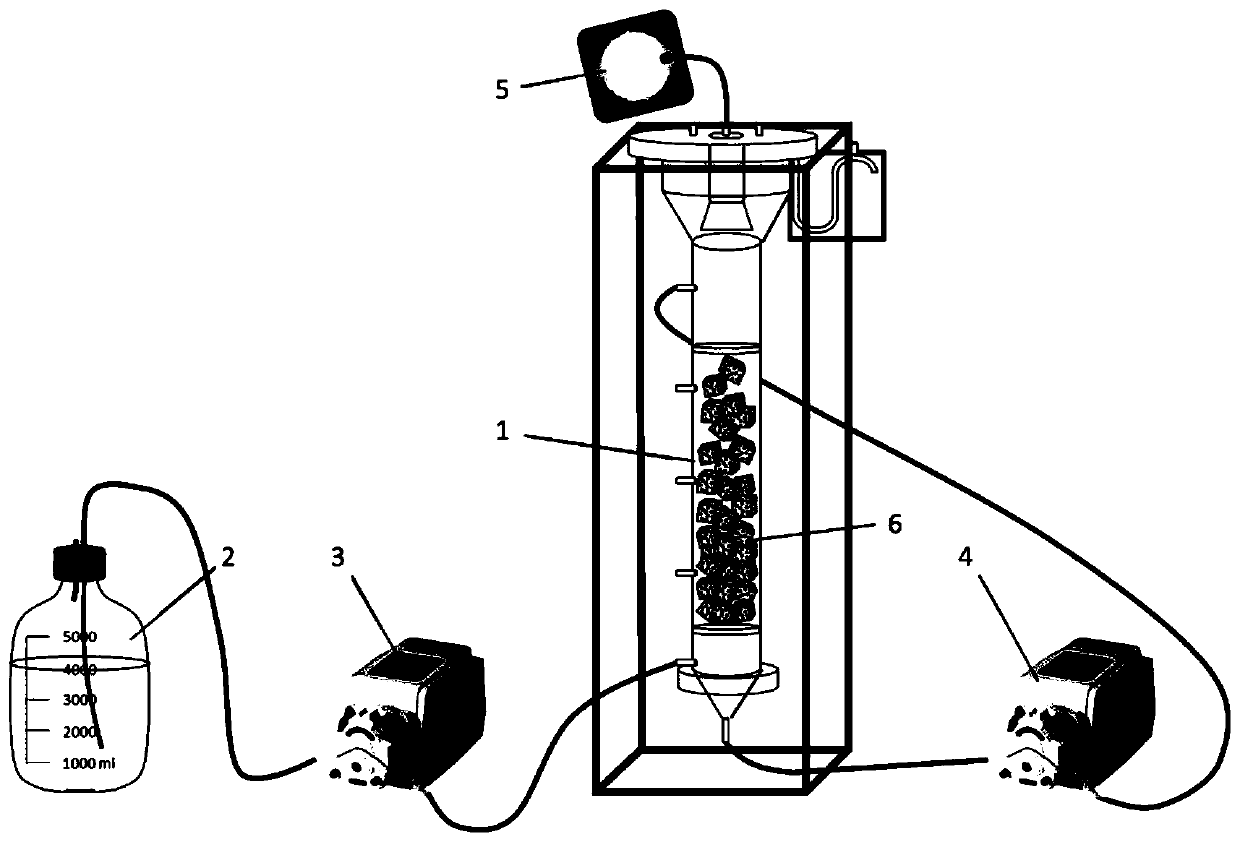

[0023] Specific embodiment 1: In this embodiment, a self-aggregating granular sludge construction method for waste water cascade energy recovery is provided. The specific operation steps of the method are as follows:

[0024] (1) Aerobic cultivation of Pseudomonas aeruginosa PqsL in a constant temperature shaker: use liquid medium A sterilized by high temperature and high pressure steam to cultivate Pseudomonas aeruginosa PqsL, and place the inoculated Erlenmeyer flask in a constant temperature shaker Vibrating culture in the bed, wherein, the temperature of the constant temperature shaker is 35°C, and the rotation speed is 100rpm. After 12 hours, a light yellow turbid bacterial liquid with an absorbance of 0.9-1.0 at a wavelength of 600nm is formed. Take 100ml-300ml of light yellow turbid bacterial liquid, 12000r Centrifuge for 1 minute at / h, discard the supernatant, and obtain the inoculum of Pseudomonas aeruginosa PqsL; wherein each 1L of liquid medium A consists of 2.0 g o...

specific Embodiment approach 2

[0030] Specific embodiment 2: This embodiment provides a cultivation method of Harbin ethanologen YUAN-3 in a continuous flow biological hydrogen production reactor. The main difference between the operation steps of this method and specific embodiment 1 is that only inoculation The other culture conditions and steps of the inoculum of Harbin ethanologen YUAN-3 are the same, and the method starts to produce hydrogen after 40 hours of culture, and the maximum hydrogen production rate is 1.62mol-hydrogen / mol-sucrose.

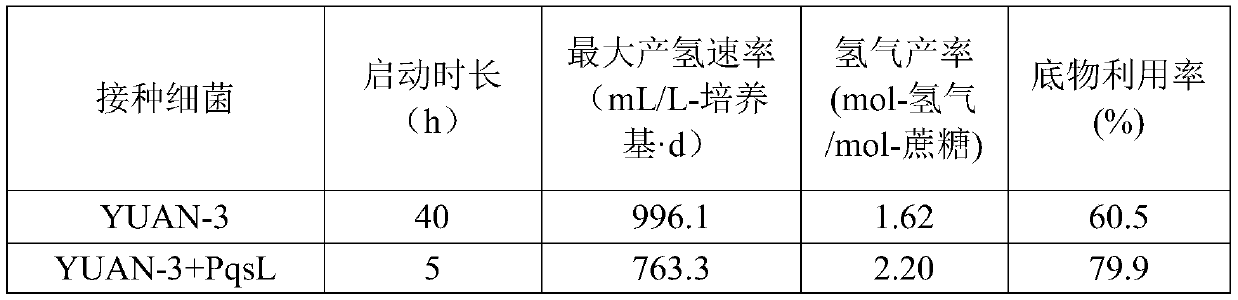

[0031] The hydrogen production effect of specific embodiment 1 and specific embodiment 2 is compared in the following table,

[0032]

[0033] It can be seen from the above table that inoculating the self-aggregated granular sludge of Harbin ethanologen YUAN-3 and Pseudomonas aeruginosa PqsL in the continuous flow biohydrogen production reactor can significantly shorten the start-up time of the continuous flow biohydrogen production reactor Simultaneously, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com