Cigar flavor essence, cigar flavor gloss oil, and tipping paper for cigarettes

A technology of tipping paper and flavor, applied in the direction of essential oil/fragrance, wrapping paper, wrapping paper, etc., can solve the problems of poor suction, insufficient aroma concentration of cigar tobacco leaves, etc., achieve stability and style characteristics, stable properties, prevent Adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

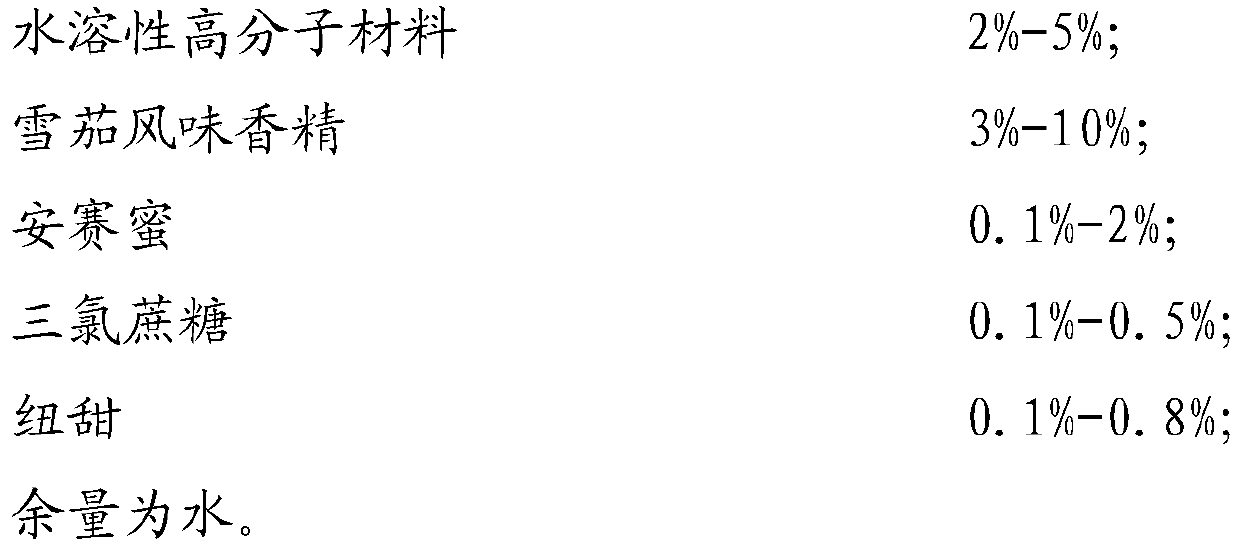

[0034] The preparation method of any one of above-mentioned cigar flavor varnish, comprises the following steps:

[0035] First, the water-soluble polymer material is uniformly dispersed in water to form a homogeneous solution;

[0036] Next, add acesulfame-K, sucralose, neotame and cigar essence to the homogeneous solution in sequence to prepare cigar-flavored varnish.

[0037] A tipping paper for cigarettes comprises any one of the above-mentioned cigar-flavored varnishes.

[0038] The preparation method of tipping paper for cigarettes comprises the following steps:

[0039] 1) Preparation of tipping paper for traditional cigarettes;

[0040] 2) Coating the cigar-flavored varnish on the surface of the traditional tipping paper for cigarettes by a gravure printing process, and then drying at a temperature of 60-90° C. to prepare the tipping paper for cigar-flavored cigarettes.

[0041] The prepared tipping paper for cigar-flavored cigarettes must be sealed and preserved. ...

Embodiment 1

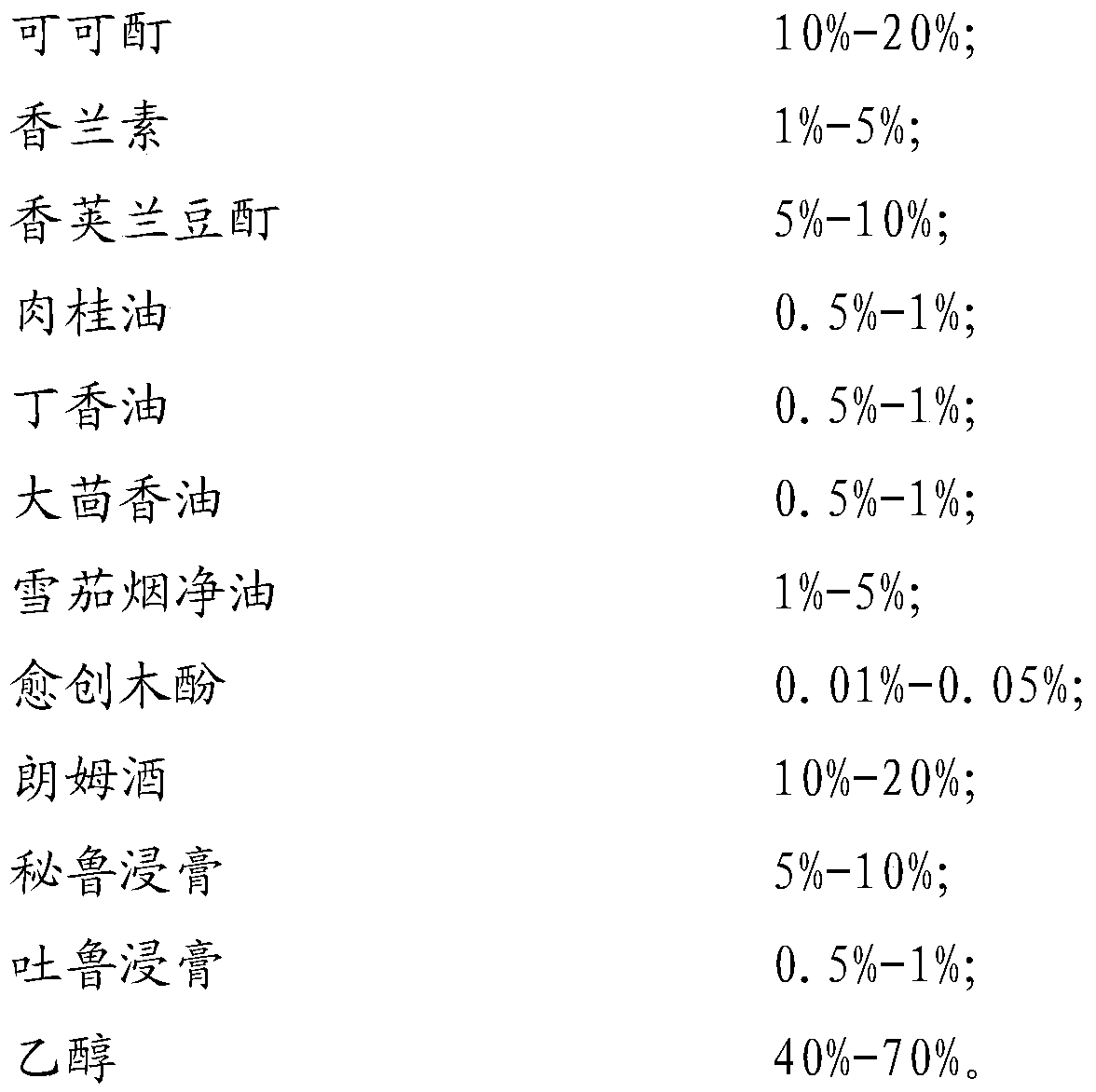

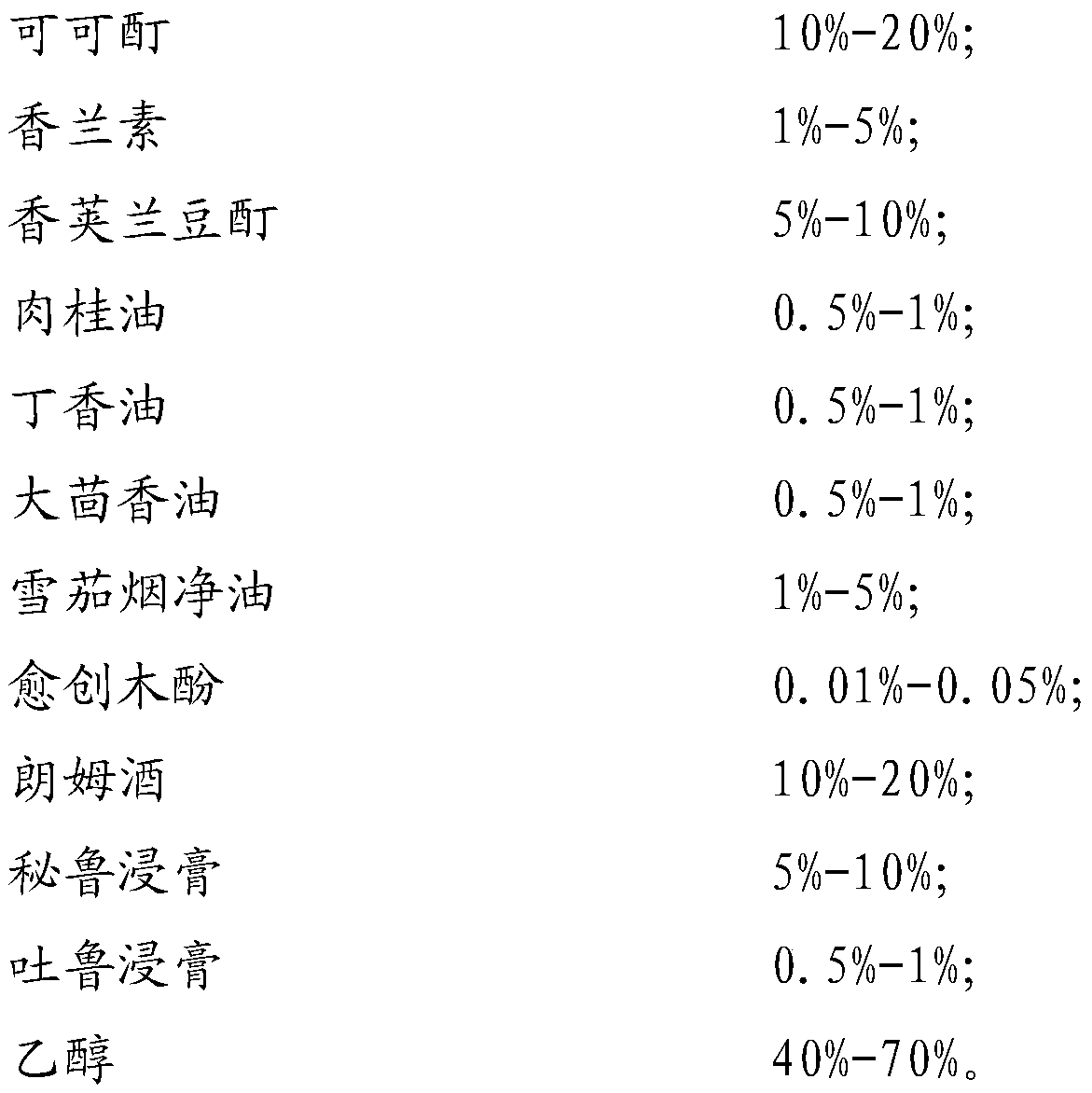

[0045] Preparation of cigar essence:

[0046] In a 500mL beaker, add cocoa tincture 15g, vanillin 2g, vanilla bean tincture 5g, cinnamon oil 0.5g, clove oil 0.5g, anise oil 0.5g, cigar smoke absolute 3g, guaiacol 0.01g , 15g of rum, 5g of Peruvian extract, 0.5g of Tulu extract, 50g of alcohol, fully stirred, and prepared cigar essence module I.

[0047] Preparation of cigar flavor varnish:

[0048] 50g of cigar essence module I, 10g of acesulfame potassium, 2g of sucralose, 4g of neotame and 20g of sodium carboxymethylcellulose were uniformly dispersed in water to obtain 300g of cigar flavor varnish.

[0049] Preparation of tipping paper for cigar-flavored cigarettes:

[0050] The cigar-flavored varnish is transferred to the surface of 10kg tipping paper through the gravure printing process, and then dried at a constant temperature at 90°C. The dried paper is then subjected to processes such as bronzing, cutting, and punching, which is the tipping paper for cigar-flavored ci...

Embodiment 2

[0052] Preparation of cigar essence:

[0053] In a 500mL beaker, add cocoa tincture 20g, vanillin 1g, vanilla bean tincture 10g, cinnamon oil 1g, clove oil 1g, anise oil 1g, cigar smoke absolute 5g, guaiacol 0.01g, rum 20g of wine, 10g of Peruvian extract, 1g of Tulu extract, and 30g of alcohol were fully stirred to obtain the cigar essence module II.

[0054] Preparation of cigar flavor varnish:

[0055] Disperse 40g of cigar essence module II, 8g of acesulfame potassium, 2.5g of sucralose, 3g of neotame and 20g of sodium carboxymethyl cellulose with water as a solvent to obtain 500g of cigar flavor varnish.

[0056] Preparation of tipping paper for cigar-flavored cigarettes:

[0057] Transfer the cigar-flavored varnish to the surface of 10kg tipping paper through gravure printing, and then dry it at a constant temperature at 70°C. Packing paper II, the mass fraction of cigar flavor varnish in the tipping paper is 0.4%, the mass fraction of acesulfame K is 0.08%, the mass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com