A kind of yogurt and preparation method thereof

A yogurt and milk technology, applied in the direction of milk preparations, other dairy products, bacteria used in food preparation, etc., to achieve the effects of optimizing the curd state, increasing the activity of lactic acid bacteria, and having a unique flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

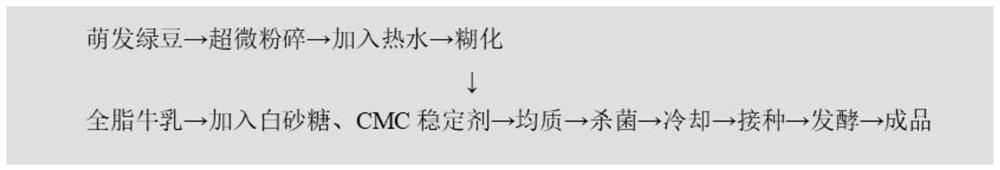

[0030] The present invention also provides the preparation method of the yogurt described in the above scheme, comprising the following steps:

[0031] 1) mixing described germinated mung bean powder and water to obtain germinated mung bean powder;

[0032] 2) mixing described milk, white granulated sugar and sodium carboxymethyl cellulose to obtain milk mixture;

[0033] 3) mixing the germinated mung bean powder in step 1) and the milk mixture in step 2), homogenizing and sterilizing, inoculating lactic acid bacteria, fermenting at 40-45°C for 4-6 hours, and cooling to obtain yogurt;

[0034] There is no time sequence restriction between the steps 1) and 2).

[0035] In the present invention, the germinated mung bean powder and water are mixed to obtain the germinated mung bean powder slurry; the temperature of the mixing is preferably 80-100°C, more preferably 90°C; the mixing method is preferably stirring and mixing; There are no special restrictions on the mixing time an...

Embodiment 1

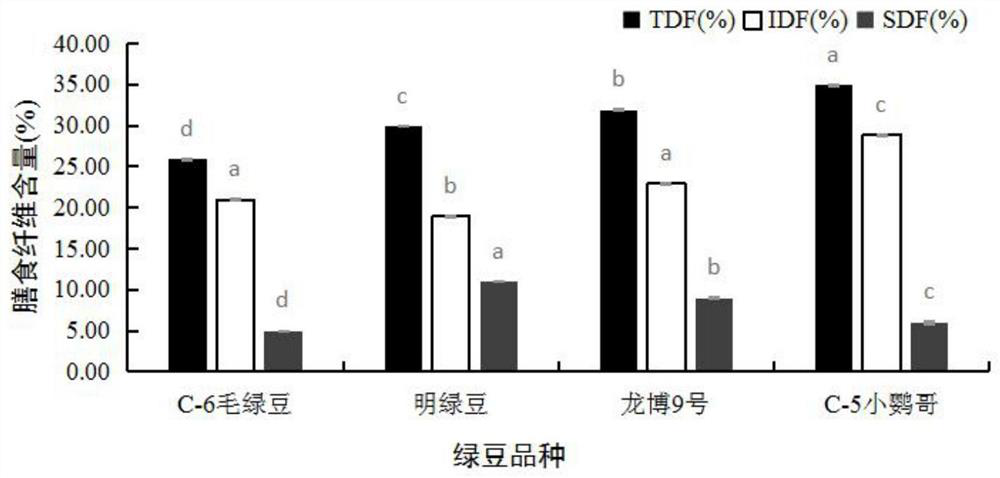

[0045] Comparison of dietary fiber content in germinated mung bean of different varieties

[0046] 1. Raw materials

[0047] Ming mung bean, Longbo No. 9 mung bean, hairy mung bean, small parrot.

[0048] 2. Mung bean germination

[0049] Germination mung bean preparation process:

[0050] Commercially available mung bean → picking, cleaning → soaking → germination, germination → germination of mung bean

[0051] The specific operation steps are as follows:

[0052] 1) Picking: Process the commercially available mung beans to remove the particles that are damp and moldy, damaged by moths, and shrunken skin, and screen out the larger and plump particles.

[0053] 2) Cleaning and disinfection: rinse the mung beans with water until the mung beans are clean, irradiate the mung beans with ultraviolet rays for 5 minutes to disinfect and soak them;

[0054] 3) Soaking: put the sample into a container, sintered with distilled water at 45°C, pour it, and soak it (gradually cooled ...

Embodiment 2

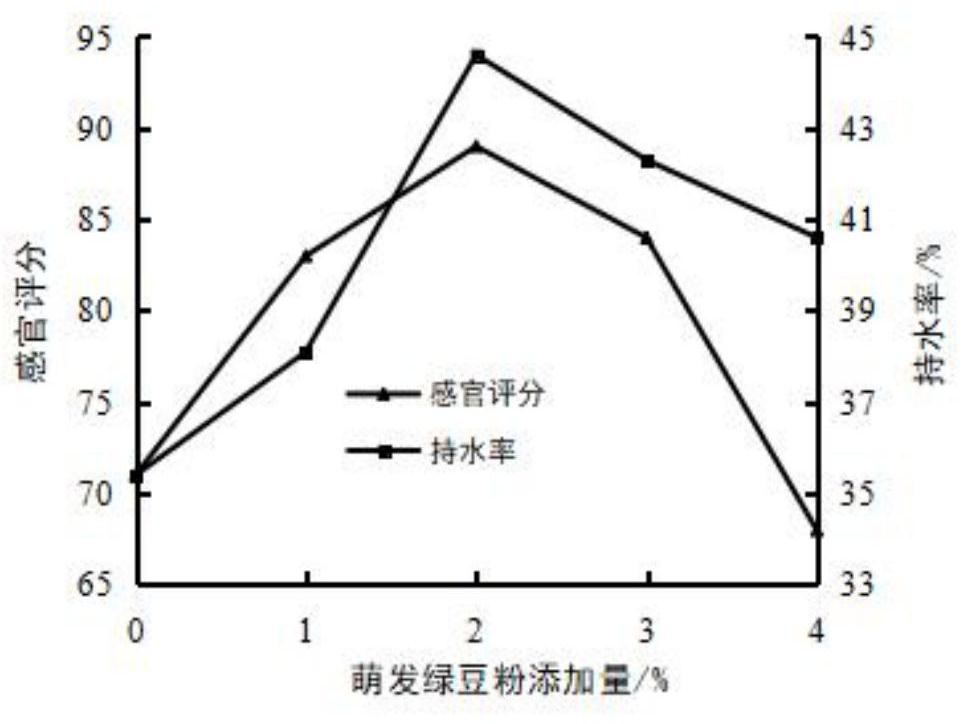

[0058] Example 2 Determination of the sensory quality of yogurt with different raw materials

[0059] For the preparation process of yogurt, see figure 2 .

[0060] 1. Raw materials

[0061] Ming mung bean germination mung bean powder, white sugar, CMC stabilizer, milk, water and lactic acid bacteria (Lactobacillus bulgaricus and Streptococcus thermophilus have a ratio of 1:1; total viable bacteria: 10 10 cfu / g~10 12 cfu / g);

[0062] Described Ming mung bean germination mung bean powder is prepared by the following method:

[0063] 1) Picking: Process the commercially available mung beans to remove the particles that are damp and moldy, damaged by moths, and shrunken skin, and screen out the larger and plump particles.

[0064] 2) Cleaning: Rinse with water until the mung beans are clean;

[0065] 3) Soaking: put the sample into a container, sintered with distilled water at 45°C, pour it, and soak it (gradually cooled to room temperature) for 24h;

[0066] 4) Germinati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com