Chemical vapor deposition method and device for preparing polycrystalline silicon carbide

A technology of chemical vapor deposition and polycrystalline silicon carbide, which is applied in the directions of chemical instruments and methods, gaseous chemical plating, polycrystalline material growth, etc., can solve the problem of less energy to prepare silicon carbide bulk materials, and avoid clogging and reduce Accumulation, small particle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

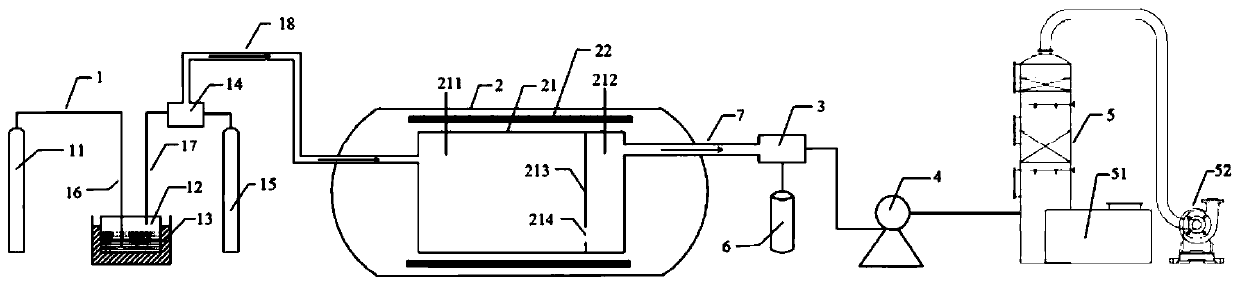

Image

Examples

Embodiment 1

[0031] This embodiment is an embodiment of the chemical vapor deposition method for preparing polycrystalline silicon carbide according to the present invention. Vacuum until the pressure is less than 5 Pa, then raise the temperature to 400-500°C within 2-4 hours, keep the temperature for 4-6 hours, then raise the temperature to 1100°C within 4-10 hours, keep the temperature for 1-2 hours, and then pass in argon until the pressure is stable and maintained at 20000±100Pa, and then pass the mixed gas of argon, hydrogen and methyltrichlorosilane to deposit for 200h and control the pressure of the chemical vapor deposition chamber to 20000±100Pa. Internally cool down to 700-800°C, keep warm for 4-6 hours, and then cool down to room temperature within 40-60 hours to obtain block polycrystalline silicon carbide, in which argon, hydrogen and methyltrichlorosilane are mixed in argon and The volume ratio of hydrogen is argon:hydrogen=1:2.

Embodiment 2

[0033] This embodiment is an embodiment of the chemical vapor deposition method for preparing polycrystalline silicon carbide according to the present invention. In this method, the volume ratio of argon to hydrogen in the mixed gas of argon, hydrogen and methyltrichlorosilane is argon: Except hydrogen=1:1.2, others are all identical with embodiment 1. Compared with Example 1, the polycrystalline silicon carbide obtained in Example 2 is looser and rougher.

Embodiment 3

[0035] This embodiment is an embodiment of the chemical vapor deposition method for preparing polycrystalline silicon carbide according to the present invention. In this method, the volume ratio of argon to hydrogen in the mixed gas of argon, hydrogen and methyltrichlorosilane is argon: Except hydrogen=1:3, others are all identical with embodiment 1. Compared with Example 1, the polycrystalline silicon carbide obtained in Example 3 is smoother and denser.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com