Copper alloy surface Ni-P-nanometer TiO2 composite plating liquid preparation and plating process

A preparation process, copper alloy technology, applied in the direction of metal material coating process, liquid chemical plating, coating, etc., can solve problems such as difficult to meet the requirements of complex sea conditions, poor surface treatment performance of propellers, etc., to achieve improved plating performance, lower lifetime cost, and reduced agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

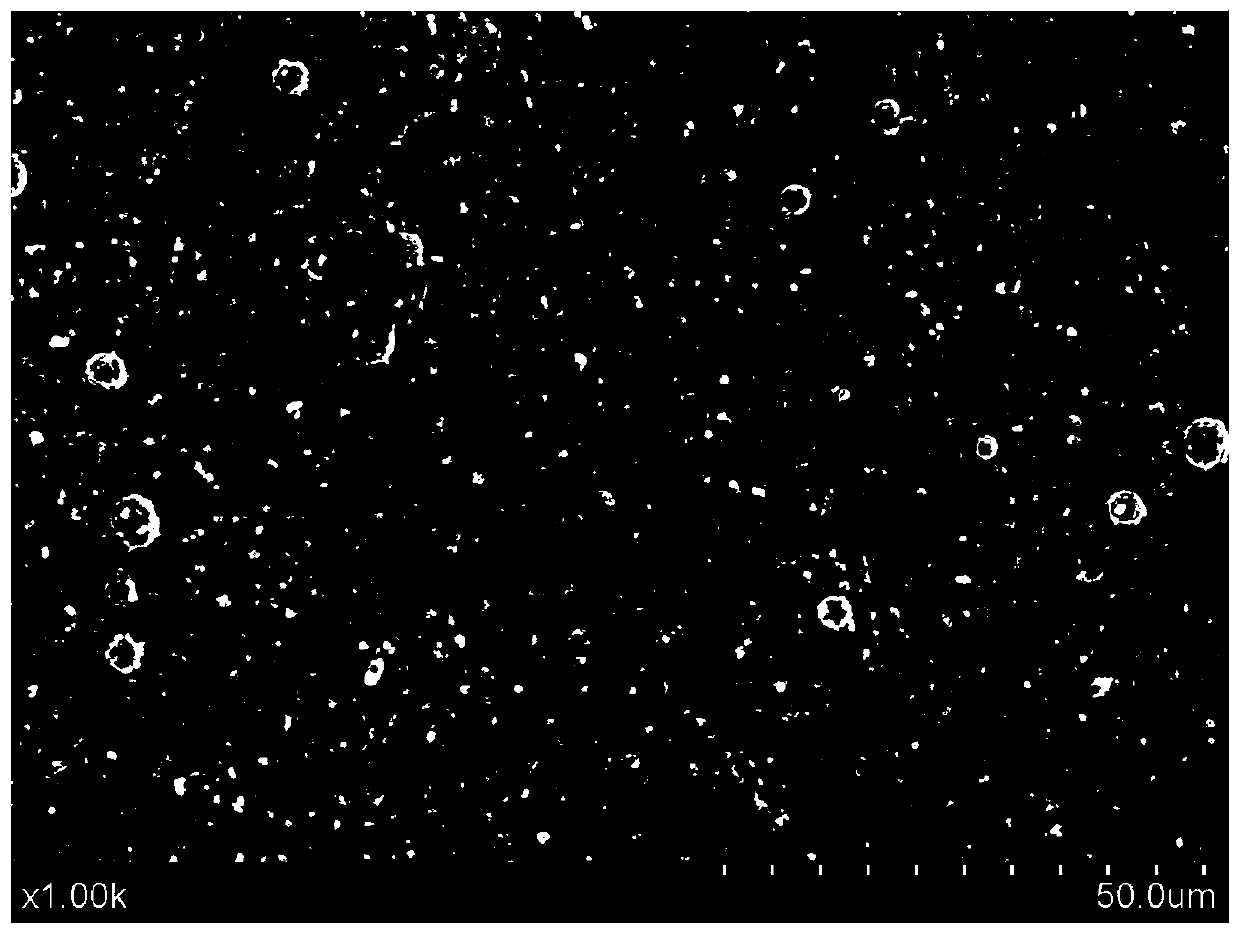

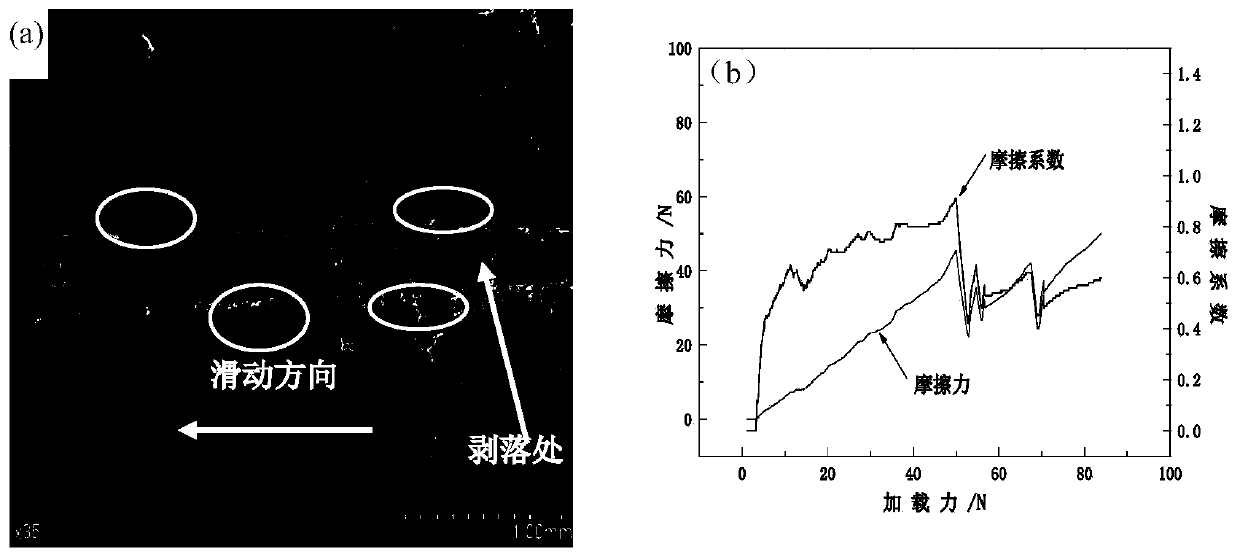

Method used

Image

Examples

Embodiment 1

[0036] Take high manganese aluminum bronze as an example:

[0037] A copper alloy surface plating process, including pretreatment and composite plating: pretreatment is to use sandpaper to grind and polish the surface of high manganese aluminum bronze, the surface roughness after grinding and polishing should be less than 6.3μm Ultrasonic cleaning for 30 minutes in a neutral solution; then pickling in 15% hydrochloric acid, take out immediately after a small amount of air bubbles appear on the surface, rinse with deionized water, dry, and complete the pretreatment; then the pretreated high manganese aluminum The bronze is placed in 5% hydrochloric acid for weak acid activation for about 30-60s. After taking it out, rinse it with deionized water and dry it. Then put the copper alloy into the following plating solution for plating:

[0038] Nickel Sulfate (NiSO 4 ·6H 2 O) 30g / L

[0039] Sodium hypophosphite (NaH 2 PO 2 ·H 2 O) 22g / L

[0040] Anhydrous sodium acetate (CH ...

Embodiment 2

[0052] Take Nickel Aluminum Bronze as an example:

[0053] A copper alloy surface plating method, which includes pretreatment and plating, the pretreatment includes grinding with sandpaper and polishing, the surface roughness of the treated nickel-aluminum bronze should be less than 6.3 microns, and then the polished Nickel-aluminum bronze was ultrasonically cleaned in an alkaline solution for 30 minutes; then pickled in 15% hydrochloric acid, and immediately removed after a small amount of air bubbles appeared on the surface, rinsed with deionized water, and dried; then placed in 5% hydrochloric acid Activate with weak acid for about 30-60s, take it out, rinse it with deionized water, dry it, and complete the pretreatment. Then put the copper alloy into the following plating solution for plating:

[0054] Nickel Sulfate (NiSO 4 ·6H 2 O) 30g / L

[0055] Sodium hypophosphite (NaH 2 PO 2 ·H 2 O) 30g / L

[0056] Anhydrous sodium acetate (CH 3 COONa) 8g / L

[0057] Citric a...

Embodiment 3

[0066] The difference between this embodiment and embodiment one is that the formulation of the plating solution is different, and the composition of the plating solution of the present embodiment is:

[0067] Nickel Sulfate (NiSO 4 ·6H 2 O) 26g / L

[0068] Sodium hypophosphite (NaH 2 PO 2 ·H 2 O) 38g / L

[0069] Anhydrous sodium acetate (CH 3 COONa) 12g / L

[0070] Citric acid (C 6 h 8 o 7 ·H 2 O) 10g / L

[0071] Lactic acid (C 3 h 6 o 3 ) 30mL / L

[0072] Nano-TiO 2 6g / L

[0073] Sodium Lauryl Sulfate 40mg / L

[0074] The balance is deionized water.

[0075] Its preparation method and plating method are the same as in Example 1. The plating effect is similar to that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com