Carbon dot-based fluorescent silicon dioxide nanosphere and preparation method thereof

A technology of silica and nanospheres, applied in chemical instruments and methods, luminescent materials, etc., can solve problems such as low luminescence quantum yield and molar absorption coefficient, restrictions on the large-scale application of quantum dots, and threats to the toxic environment. Effects of low cytotoxicity, surface modification, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1 Preparation of carbon dot-based fluorescent silica nanospheres

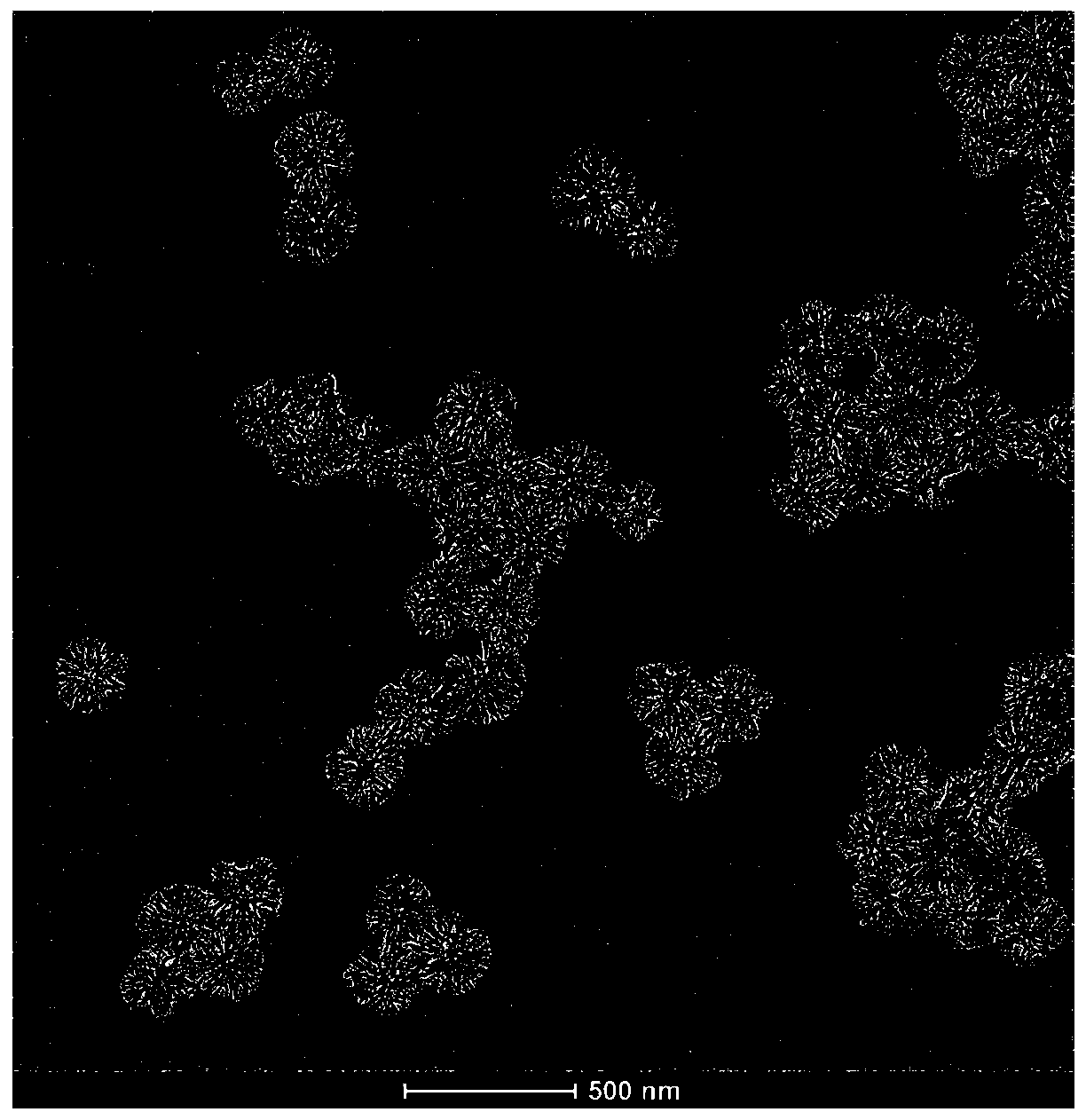

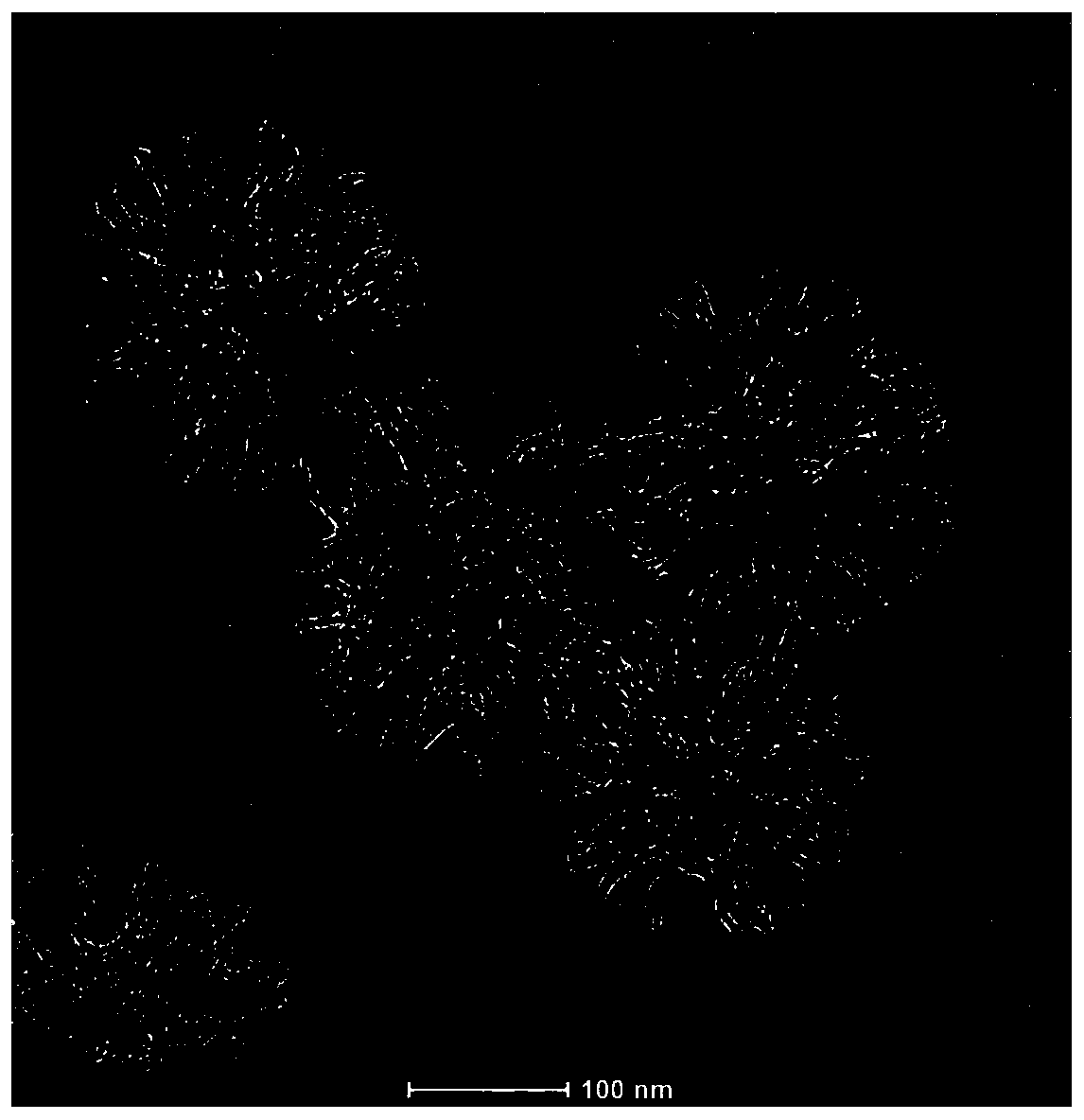

[0038] (1) Pour 15mL of N-β-(aminoethyl)-γ-aminopropyltrimethoxysilane into a 50mL three-necked flask, and after purging with nitrogen for a period of time, heat the solution to 240°C. Quickly add 0.075, 1, 2, 4, 6, 7.5 g of dehydrated citric acid under stirring. After reacting for 5 minutes, stop heating and cool the solution naturally, and centrifuge the obtained solution at high speed to remove large particles at the bottom to obtain silanization Carbon dots. The silylated carbon dots obtained by different quality dehydrated citric acid only affect the concentration of carbon dots in the final product but not the properties of carbon dots. Among them, the pictures of silanized carbon dots obtained by adding 1g of dehydrated citric acid under fluorescent lamp and ultraviolet lamp are as follows: figure 1 As shown, its quantum yield is 47%.

[0039] (2) Add 68 mg of triethanolamine to 25 mL o...

Embodiment 2

[0041] Example 2 Preparation of carbon dot-based fluorescent silica nanospheres

[0042] The difference between this embodiment and Example 1 is: the quality of dehydrated citric acid in the step of preparing silylated carbon points in step (1) is 1g, and the time of reaction heating is respectively 1, 3, 7, 10, 15, 20, 30min. Others are the same as in Example 1. Different reaction heating times only affect the concentration of carbon dots in the final product but not the properties of carbon dots.

Embodiment 3

[0044] The difference between this example and Example 1 is that the quality of dehydrated citric acid in the step of preparing silylated carbon dots in step (1) is 1 g, and in step (2) 10 mg of triethanolamine, 100 mg of CTAB, 10 mg of sodium salicylate and TEOS 1mL. Others are the same as in Example 1, the morphology of the fluorescent nanospheres obtained is the same as Figure 4 similar.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com