A kind of isosteviol metal gel and its preparation method and application

A gel and silver alcohol sulfonate technology, which is applied in metal processing equipment, sulfonate preparation, transportation and packaging, etc., can solve the problems of pollution and cost increase, and achieve the effect of avoiding agglomeration, avoiding heating and removal, and less pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

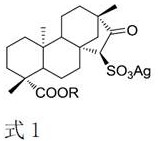

[0041] The preparation of embodiment 1 isosterveol isopropyl ester silver sulfonate

[0042] Dissolve isosteviol (5g 16mmol) in acetonitrile (31mL), add K 2 CO 3 (1.79g 32mmol), stirred with a magnetic stirrer in a 100mL flask, after the dissolving of isopropyl bromide, added 1.96g of isopropyl bromide, refluxed for 6 hours, TLC monitored the reaction process, after the reaction was complete, evaporated Acetonitrile. Add 200 mL of 5% dilute hydrochloric acid into the system, stir and wash, suction filter, wash with double distilled water repeatedly, collect and dry the filter cake to obtain isosterveol isopropyl ester (compound 2) as a white solid.

[0043] Under ice-bath conditions, add 1 mL of concentrated sulfuric acid to a 50 mL volumetric flask, and add acetic anhydride (6 mL) dropwise into the concentrated sulfuric acid with a constant pressure funnel under stirring. 3.7 g of isopropyl isosterveol was added therein. Stir until the reaction is complete, evaporate the ...

Embodiment 2

[0044] The preparation of embodiment 2 isosterveol isopropyl ester sulfonate silver gel

[0045]Weigh 2 mg of the above-prepared isosterveol isopropyl ester sulfonate silver compound, add it into a 5 mL pressure-resistant sample bottle, add chloroform gel solvent, ultrasonically disperse the gel, and let it stand for 24 hours. Use the inversion method to test whether the gel is formed and the minimum gel concentration. The phase transition temperature at different gel concentrations was tested by gradient heating method.

Embodiment 3

[0046] The preparation of embodiment 3 nanometer silver

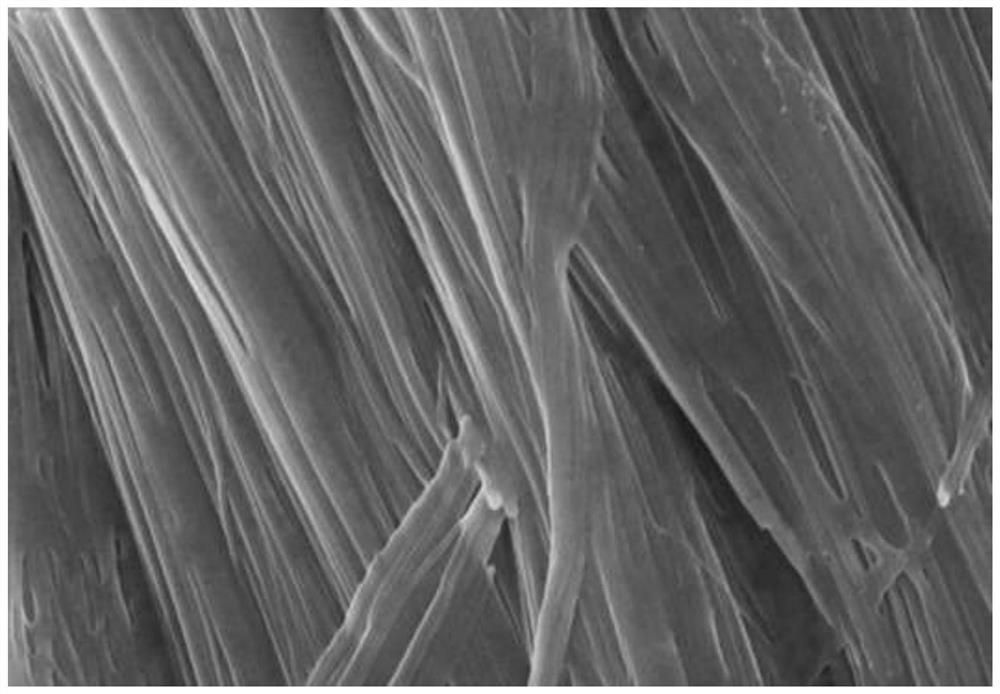

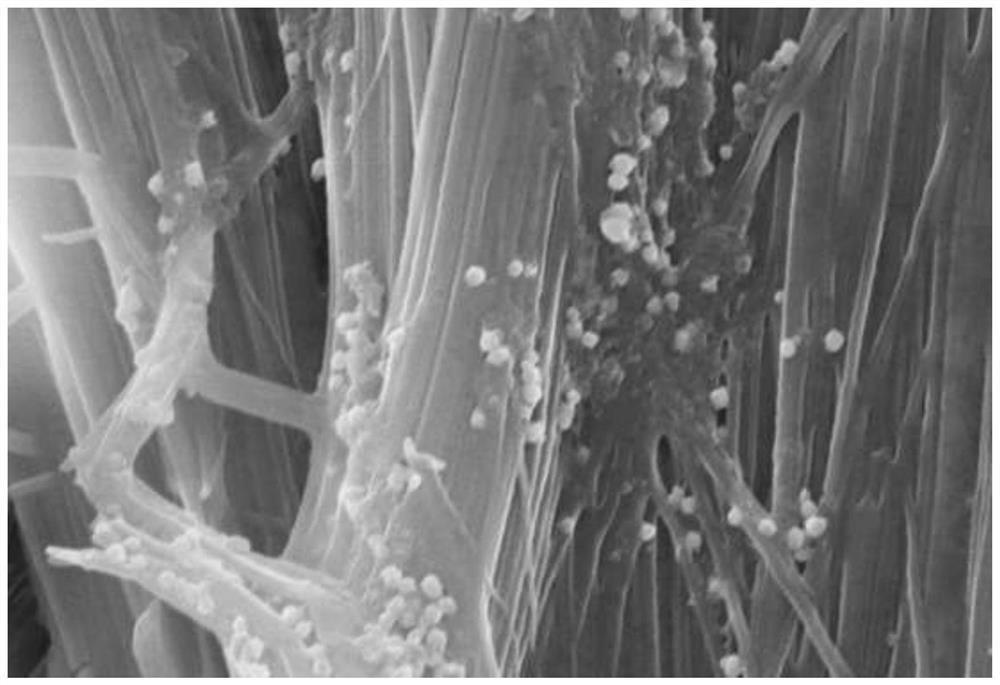

[0047] Put the isosterveol isopropyl ester sulfonate silver gel in the bottle under natural light for 3 days or 365nm ultraviolet lamp for 30 minutes, the system will gradually turn black to obtain the nano silver gel system. The prepared gel system containing nano-silver was transferred to a silicon wafer, and dried naturally to obtain a xerogel sample. After spraying gold for 30 seconds, the gel morphology was observed under a scanning electron microscope. Ribbon-like nanostructures self-assembled by the gelling agent can be observed. After photoreduction, nano-silver is evenly attached to the gel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com