Active kaolin modified formaldehyde-free vegetable albumen glue as well as preparation method and application thereof

A technology of active kaolin and vegetable protein glue, applied in the field of active kaolin modified formaldehyde-free vegetable protein glue and its preparation field, can solve the problems of difficult to stabilize formaldehyde emission, low degree of automation, difficult to control the pot life of glue, etc. Industrial production, simple preparation process, and the effect of eliminating formaldehyde release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

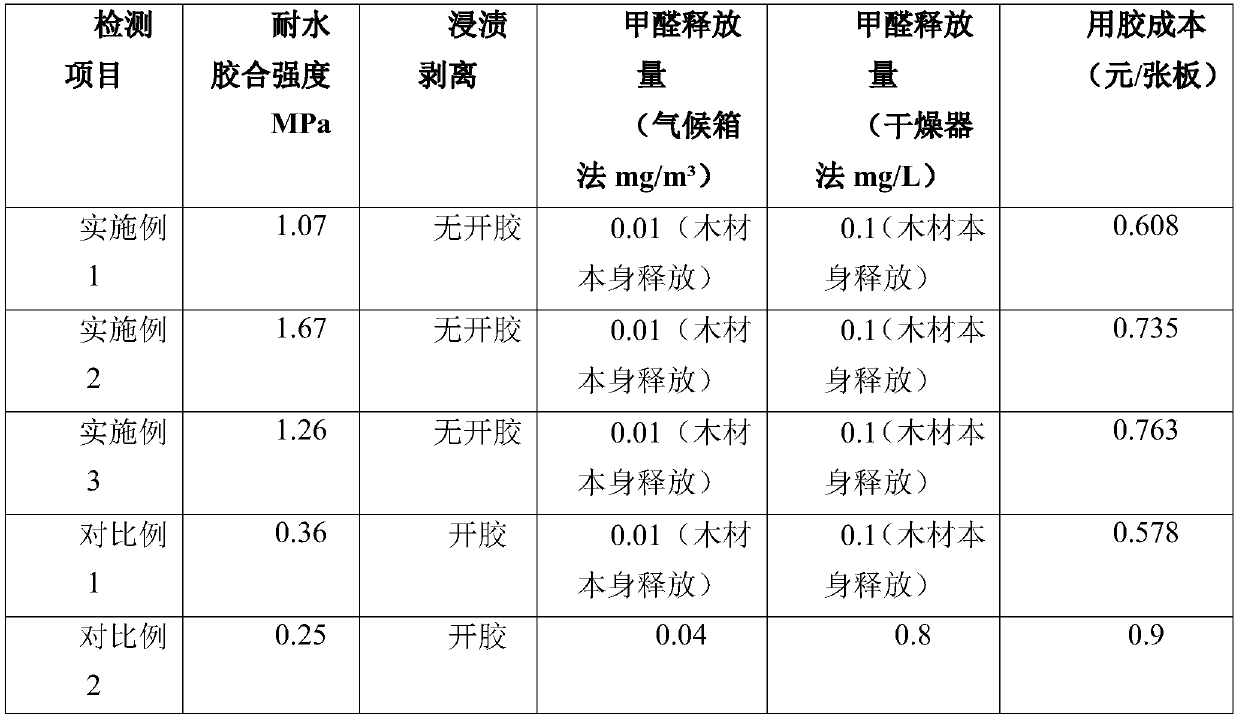

Examples

Embodiment 1

[0025] 1) Preparation of activated kaolin:

[0026] In parts by weight, add 1 part of KH560 silane coupling agent and 10 parts of glycerol triglycidyl ether dispersant successively in the reaction kettle, stir for 10 minutes until uniform, and obtain the intermediate, and then mix the intermediate with 100 parts of kaolin in Mix in a high-speed mixer for 15 minutes until uniform, and the activated kaolin is obtained;

[0027] 2) Preparation of active kaolin modified formaldehyde-free vegetable protein glue:

[0028] In parts by weight, 100 parts of water-based crosslinking agent polyamidoamine-epichlorohydrin resin aqueous solution with 5% solid content, 40 parts of high-temperature soybean meal powder, 10 parts of activated kaolin, and sodium lignosulfonate were successively added to the reaction kettle. 2 parts, stirred for 20 minutes until uniform, that is, the activated kaolin modified formaldehyde-free vegetable protein glue is obtained, and the cost of raw materials is ...

Embodiment 2

[0034] The implementation steps are the same as in Example 1, and the high-temperature soybean meal powder in Example 1 is changed to cottonseed protein powder to obtain activated kaolin modified formaldehyde-free vegetable protein glue, and the cost of raw materials is 2100 yuan / ton.

[0035] According to the A-type test piece in 4.17 of GB / T 17657-2013 (the experimental material is 3.2mm poplar veneer), use the method specified in 4.17.5.2.2 to pretreat the test piece (soak in water at 63°C for 3 hours). The prepared active kaolin-modified formaldehyde-free vegetable protein glue was tested for water resistance, and the test result was 1.67MPa.

[0036] Use the above-mentioned active kaolin modified formaldehyde-free vegetable protein glue to roll coat the side of the slats, the glue amount is 350g / sheet, hot press after billet assembly, hot press parameters: front pressure 0.6MPa, side pressure 1.0MPa , the hot pressing temperature is 160°C, and the time is 180 seconds. The...

Embodiment 3

[0039] 1) Preparation of activated kaolin:

[0040] Add 1.5 parts of KH570 silane coupling agent and 12 parts of polyethylene glycol diglycidyl ether dispersant in sequence in the reaction kettle, stir for 30 minutes until uniform, and obtain the intermediate, and then mix the intermediate and 100 parts of kaolin in a high-speed mixer Mix for 20 minutes until uniform, and the activated kaolin is obtained;

[0041] 2) Preparation of active kaolin modified formaldehyde-free vegetable protein glue:

[0042] Add 100 parts of water-based crosslinking agent polyamidoamine-epichlorohydrin resin aqueous solution with 5% solid content, 25 parts of high-temperature soybean meal powder, 20 parts of activated kaolin, and 3 parts of sodium lignosulfonate in the reaction kettle, and stir for 20 minutes to Uniform, that is, the activated kaolin-modified formaldehyde-free vegetable protein glue is obtained, and the raw material cost is 2180 yuan / ton;

[0043] According to the A-type test pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com