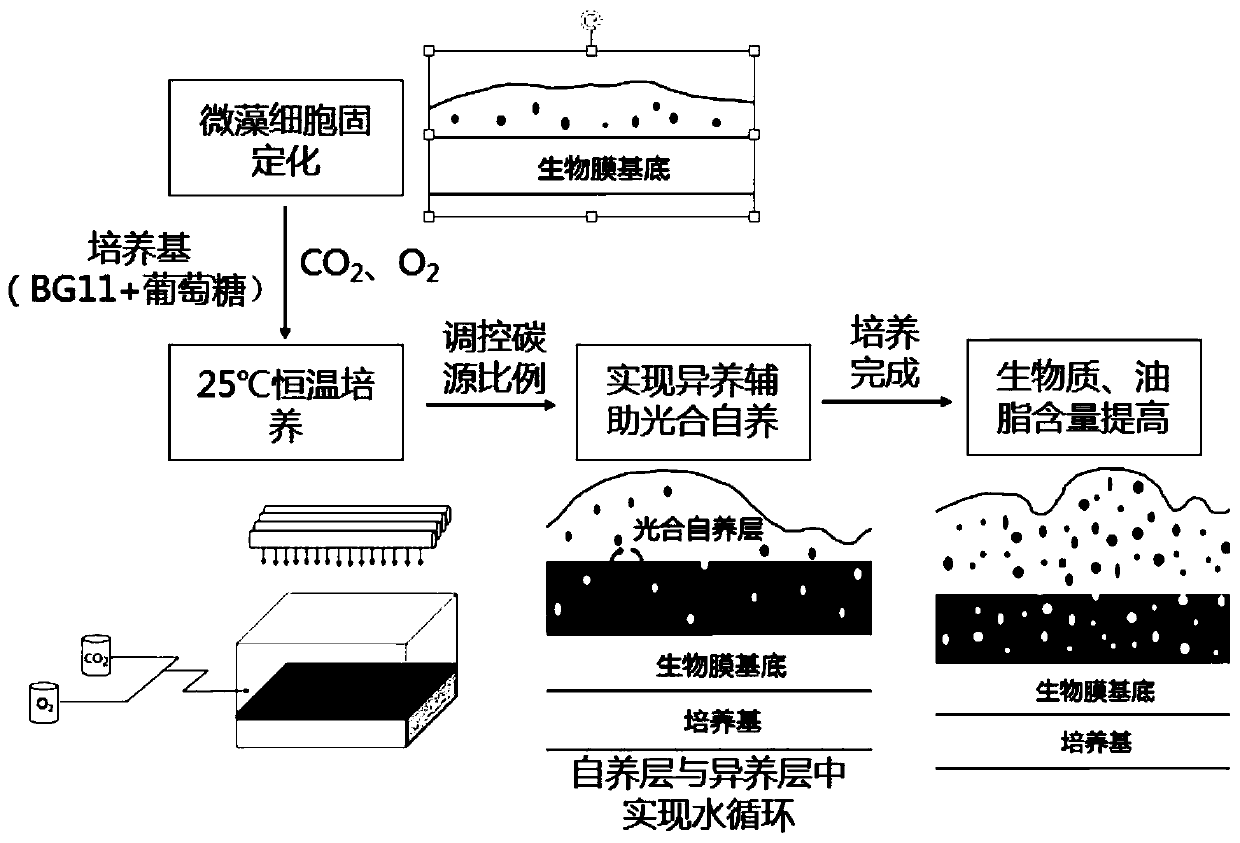

Microalgae biomembrane culture method capable of simultaneously improving biomass yield and oil yield

A technology of microalgae biology and culture method, applied in the direction of microorganism-based method, biochemical equipment and method, method of supporting/immobilizing microorganisms, etc., can solve the problems of microalgae cell growth limitation, unfavorable nutrient transmission, etc., and achieve effective It is beneficial to the growth of microalgae, optimizes the ratio of dosage, and improves the effect of yield and oil content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0035] Embodiment 2: It is different from Embodiment 1. Step 1 uses Chlorella vulgaris (Chlorellavulgaris, FACHB-31) as the culture object; in step 3, select the combination of standard BG11 medium and 10g / L plus glucose carbon source to regulate and optimize the medium, so that the inorganic carbon and organic The ratio of carbon is 29:1 and the ratio of total carbon to total nitrogen is 96:1. In Step 4, the medium was sterilized in a sterilizing pot at 121° C. for 20 minutes and cooled to inoculate the microalgae biofilm, and then the microalgae biofilm was cultured at a constant temperature of 25° C. for 5 days.

[0036] After measurement, it is known that the biomass of Chlorella vulgaris microalgae biofilm is 79.80g / m 2 , the fat content is 21.65%. The specific measurement method is as follows:

[0037] Biomass measurement method: Use tweezers to remove the two microalgae membranes in the microalgae photobioreactor, add 10mL of first-grade deionized water to fully rins...

Embodiment 3

[0039] Example 3: The difference from Example 2 is that the ratio of inorganic carbon to organic carbon in the culture medium is 20:1, and the ratio of total carbon to total nitrogen is 96:1.

[0040] After measurement, it is known that the biomass of Chlorella vulgaris biofilm is 124.94g / m 2 , The oil content was 19.94%. Compared with the cultivation effect of Example 2, the biomass accumulation of the microalgae biofilm increased significantly by 56.57%, but the oil content decreased by 7.90%. Concrete measuring method is with embodiment 2.

example 4

[0041] Example 4: The difference from Example 2 is that the ratio of inorganic carbon to organic carbon in the medium is 29:1, and the ratio of total carbon to total nitrogen is 72:1.

[0042] After measurement, it is known that the biomass of Chlorella vulgaris biofilm is 75.22g / m 2 , the oil content was 33.43%. Compared with Example 2, the oil content of the microalgae biofilm increased significantly by 54.41%, but the biomass output of the biofilm was low, which decreased by 5.33%. Concrete measuring method is with embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com