A method for preparing atomically dispersed zinc-carbon-nitrogen materials for supercapacitors

A zinc-carbon-nitrogen material and supercapacitor technology, applied in the direction of hybrid capacitor electrodes, etc., can solve the problems of low activation degree of the overall carbon material and low metal retention, and achieve excellent cycle stability, high specific capacity, and high safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

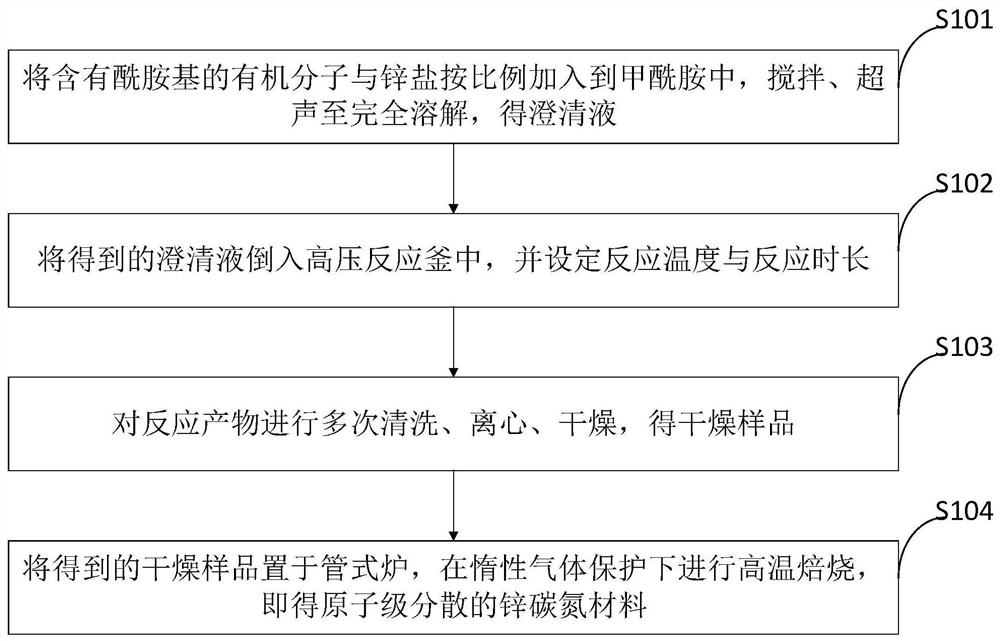

[0064] Such as figure 1 As shown, the preparation method of the atomically dispersed zinc-carbon-nitrogen material for supercapacitors provided by the embodiments of the present invention includes:

[0065] S101, adding an organic molecule containing an amide group and a zinc salt in proportion to formamide, stirring and sonicating until completely dissolved to obtain a clear liquid.

[0066] S102, pour the obtained clarified liquid into the autoclave, and set the reaction temperature and reaction time.

[0067] S103, washing, centrifuging, and drying the reaction product multiple times to obtain a dry sample.

[0068] S104, placing the obtained dry sample in a tube furnace, and performing high-temperature roasting under the protection of an inert gas to obtain an atomically dispersed zinc-carbon-nitrogen material.

[0069] In step S101, the organic molecules containing amide groups and the zinc salt provided by the embodiment of the present invention specifically include: ...

Embodiment 1

[0084] Add 1 g of zinc chloride and 1.2 g of nicotinamide into 30 ml of formamide, and ultrasonicate for 30 minutes to completely dissolve the zinc chloride into the formamide, and the solution is in a clear state at this time. The solution was moved into a high-temperature reaction kettle, and reacted at 180 degrees Celsius for 6 hours. After the reaction, wash with water and ethanol several times, centrifuge and dry at 70°C. The obtained dried samples were ground in a mortar, placed in a tube furnace and roasted under the protection of nitrogen. The roasting temperature was 900 degrees Celsius, and the roasting time was 1 hour. The calcined product is atomically dispersed zinc-nitrogen-carbon material.

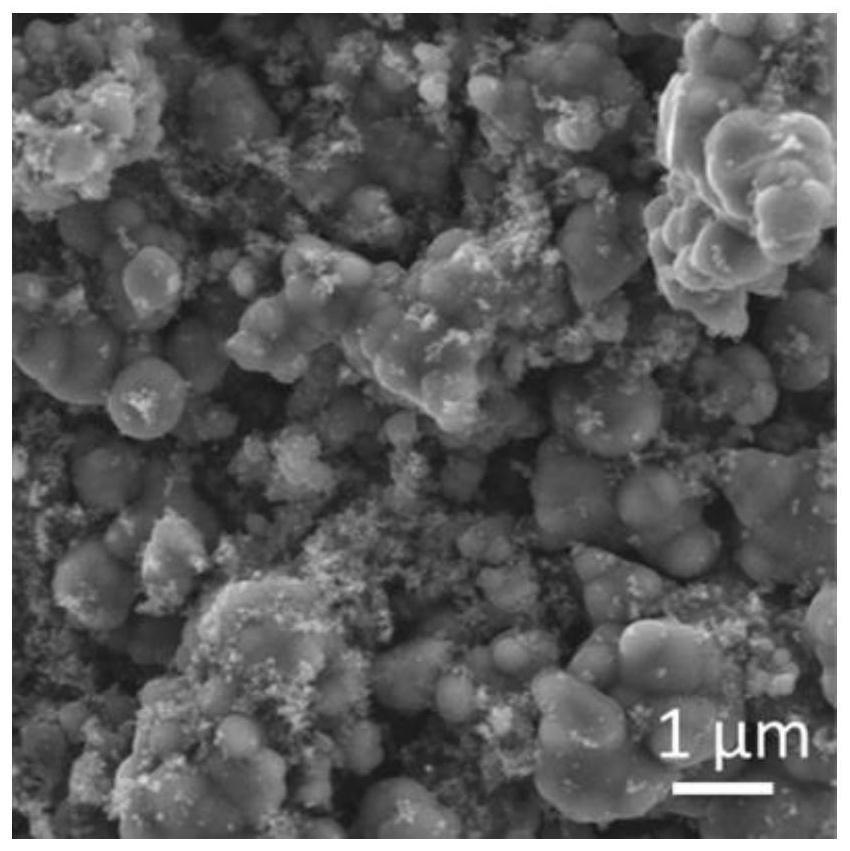

[0085] The scanning electron microscope pictures of the single-atom zinc-nitrogen doped carbon material obtained specifically can be found in figure 2 . Electron microscope results show that the prepared monoatomic zinc-nitrogen doped carbon material is a short spherical...

Embodiment 2

[0093] Except that 1.2 g of nicotinamide was replaced by 1 g of benzamide, the others were the same as in Example 1.

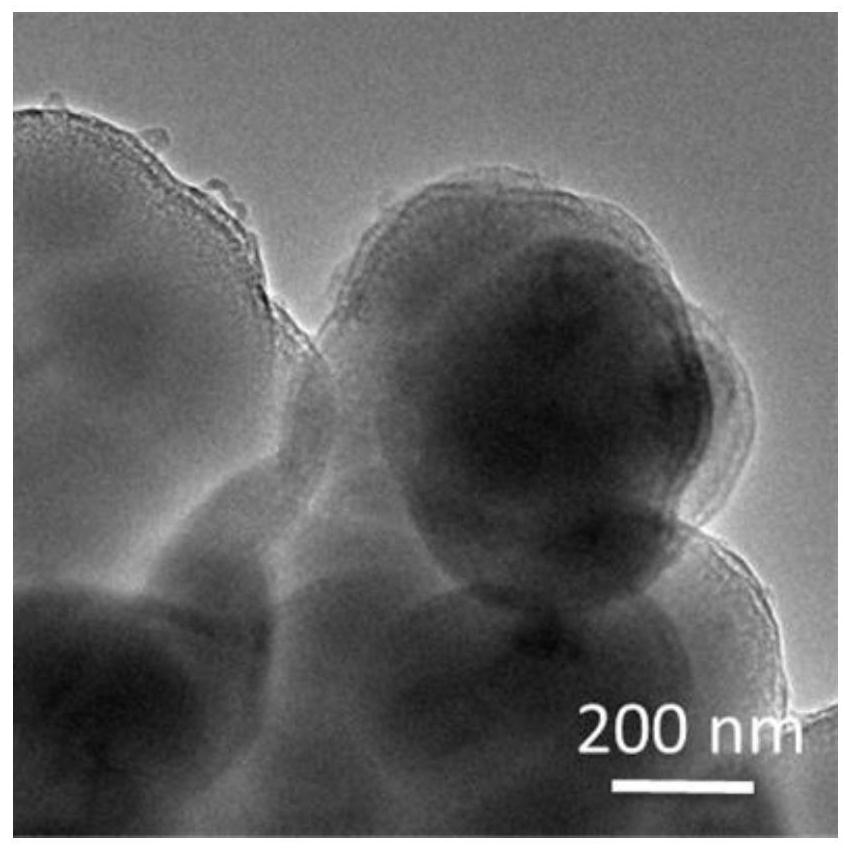

[0094] For the scanning electron microscope photo of the monoatomic zinc-nitrogen doped carbon material obtained specifically, see Figure 13 . Low magnification TEM pictures see Figure 14 .

[0095] Element distribution picture see Figure 15 .

[0096] Spherical aberration SEM photo see Figure 16 . Electron microscopy results show that the single-atom zinc-nitrogen-doped carbon material is an interconnected spherical porous amorphous material, and metal zinc is indeed doped in the material in atomic form and at high density.

[0097] Figure 17 It is an X-ray diffraction spectrum, and the curve shows only graphitized carbon peaks, further confirming that there is no state of atomic aggregation.

[0098] The test results of BET specific surface area and pore size distribution can be found in Figure 18 with Figure 19 . Figure 18 It is the BET n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com