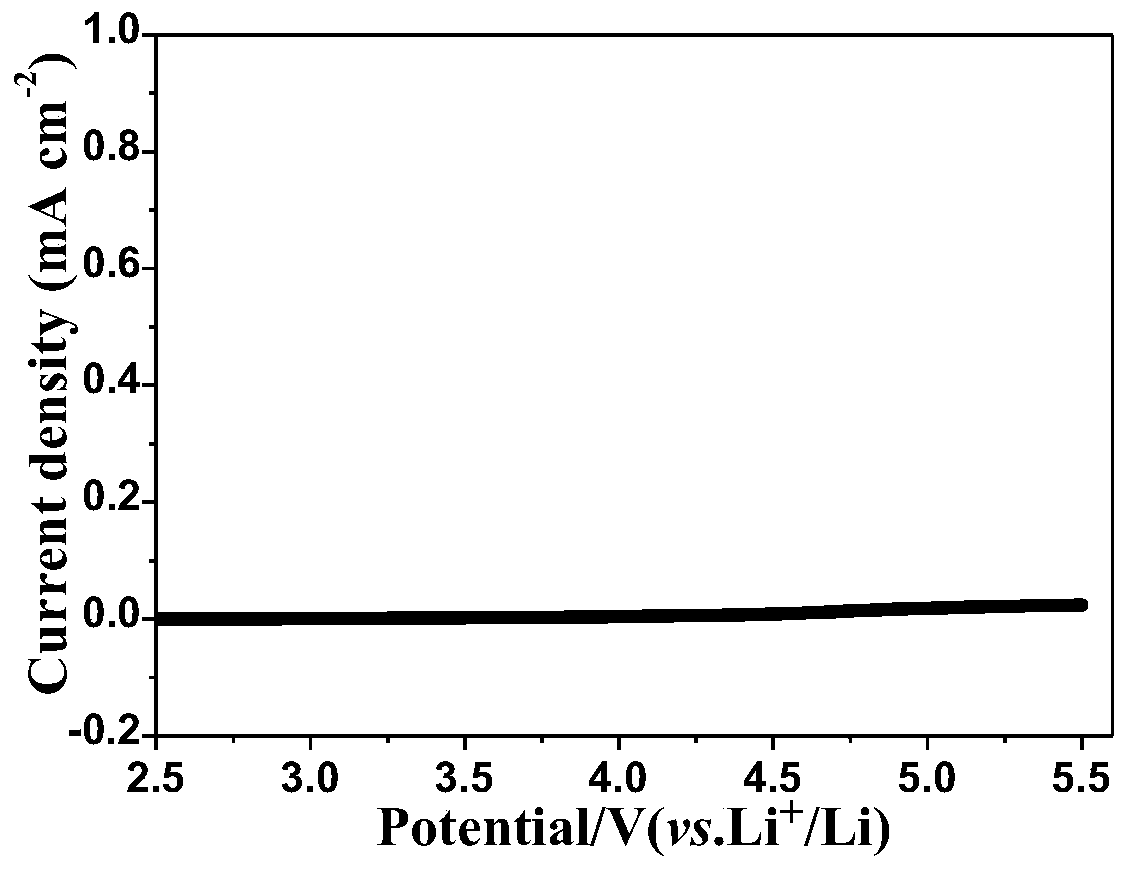

Polymer electrolyte of high-voltage window

A polymer and high-voltage technology, applied in organic electrolytes, non-aqueous electrolytes, circuits, etc., can solve problems such as side leakage of electrolyte, unstable size and performance, and inapplicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

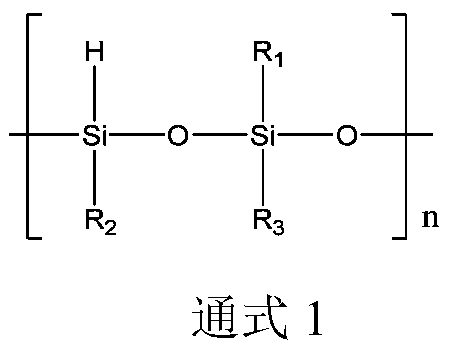

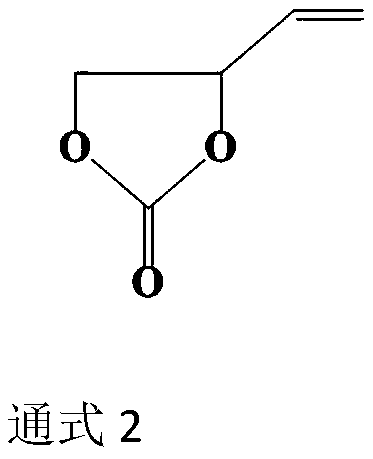

Embodiment 1

[0032] 1.3g ethylene carbonate, 1.5g phenyl hydrogen-containing silicone oil, 0.65g lithium bistrifluoromethanesulfonylimide (LiTFSI) lithium perchlorate (LiClO 4 ) into 4ml of acetonitrile, stirred at room temperature to dissolve completely; add 0.015g of azobisisobutyronitrile and stir evenly, and evenly coat it on the polytetrafluoroethylene mold cavity; heat at 90°C in a vacuum oven for 12 hours to solidify and form a film .

Embodiment 2

[0034] 2g ethylene carbonate, 2g methyl hydrogen silicone resin, 0.8g lithium perchlorate (LiClO 4 ) into 4ml of NMP, stirred at room temperature to dissolve completely; add 0.02g of bis(acetylacetonate) dibutyltin and stir evenly, and evenly apply to the polytetrafluoroethylene mold cavity; heat at 90°C in a vacuum oven for 12 hours to cure film forming.

Embodiment 3

[0036] Dissolve 1.8g of ethylene carbonate, 2g of methyl hydrogen-containing silicone resin, and 0.7g of lithium bistrifluoromethanesulfonimide (LiTFSI) into 4ml of tetrahydrofuran, stir at room temperature to dissolve completely; add 0.02g of platinum catalyst Stir evenly, and evenly apply to the polytetrafluoroethylene mold cavity; heat at 90°C in a vacuum oven for 12 hours to solidify and form a film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com