Micro-injection glass needle breaking device and method for insects

A microinjection and glass needle technology, which is applied to machine tools, stone processing equipment, grinding machines, etc., which are suitable for grinding the edge of workpieces, can solve the problems of small microinjection needle tip diameter, expensive platinum wire, and unaffordable funds. Achieve the effect of reducing the possibility of random breakage, improving the success rate of production, and avoiding clogging of the needle tip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to further set forth the technical scheme of the present invention, the present invention will be further described below by way of examples.

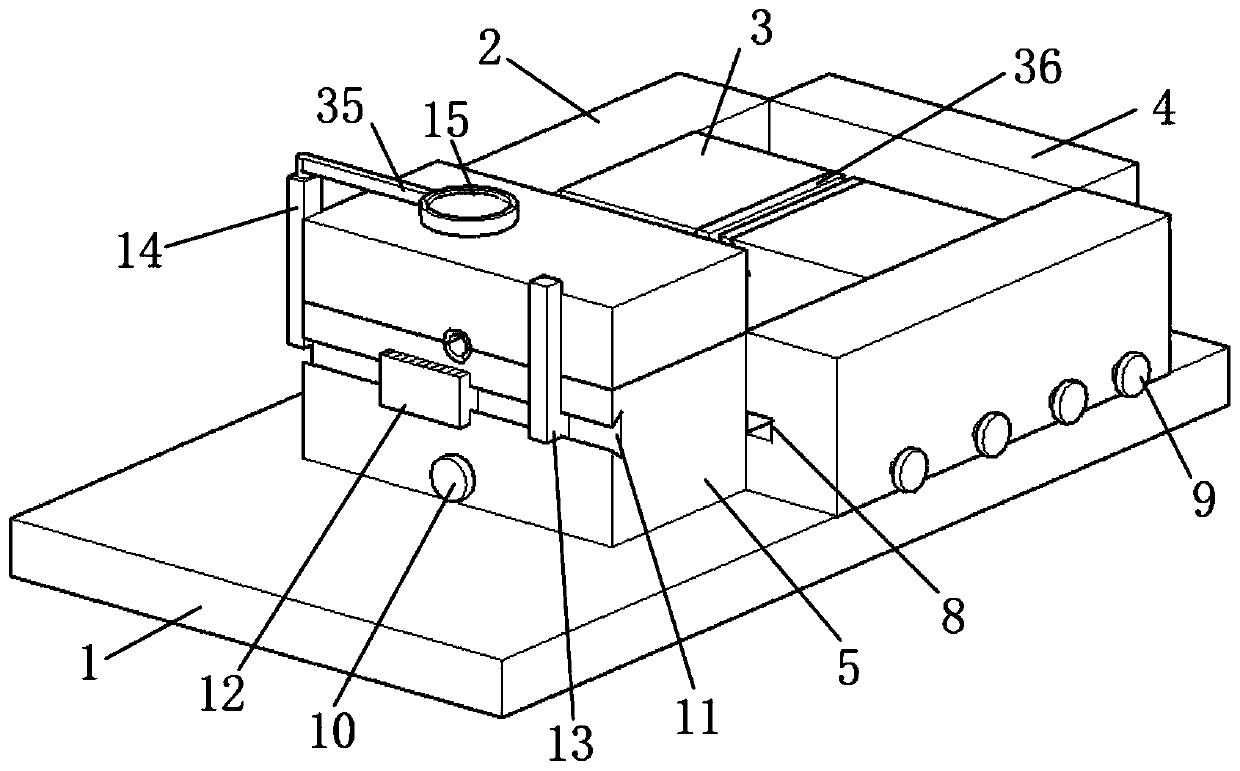

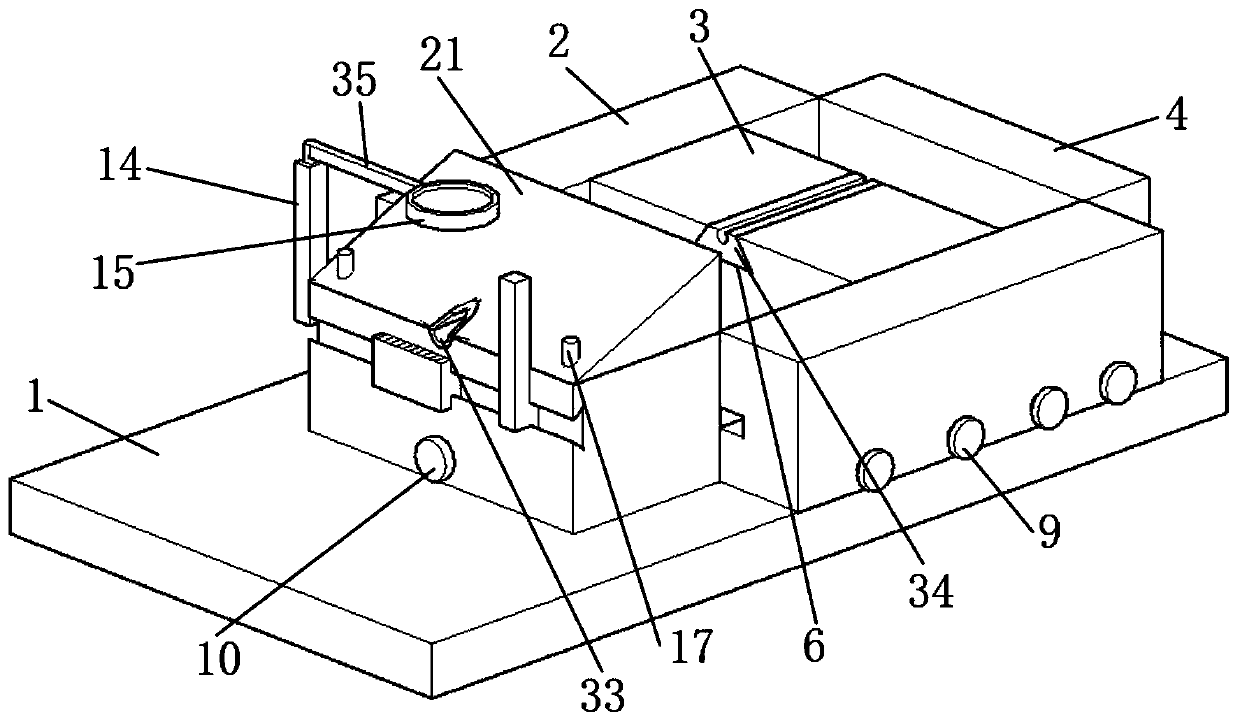

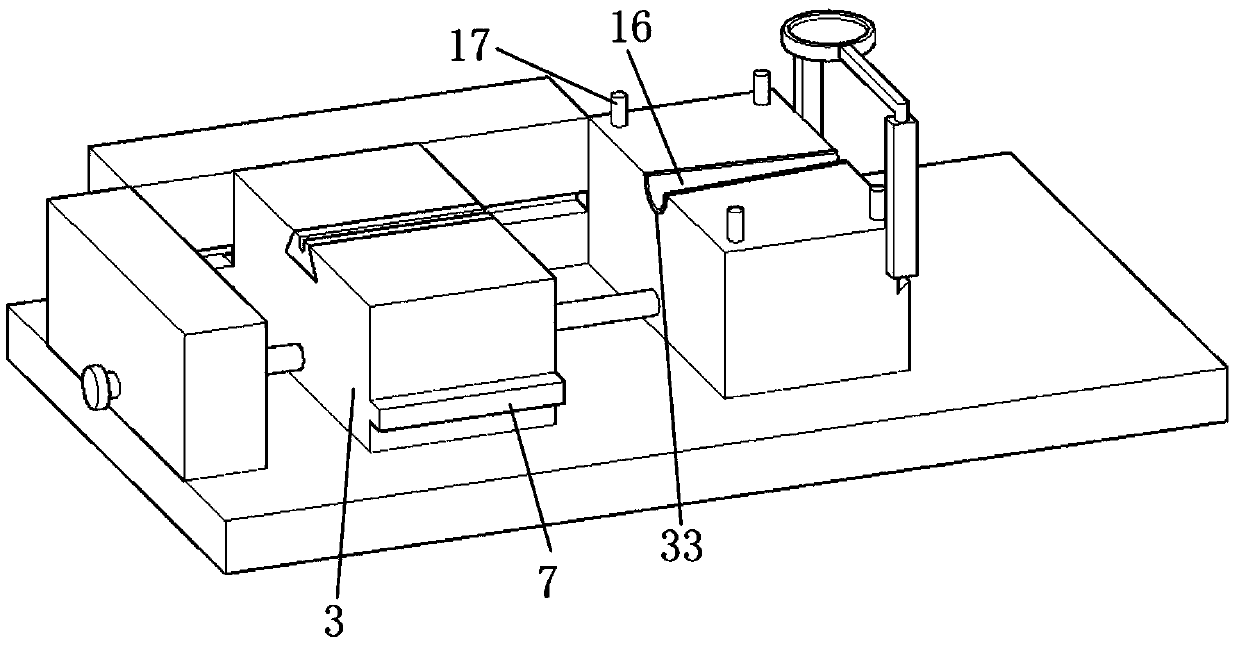

[0040] Such as Figure 1 to Figure 9 As shown, a needle breaking device for microinjection glass needles for insects, including a base plate 1, two bases 2 symmetrically arranged on the left and right sides of the base plate 1, and a slider arranged between the two bases 2 3. The fixed block 4 arranged at the rear ends of the two bases 2 and above the bottom plate 1, the fixed support block 5 arranged at the front ends of the two bases 2 and above the bottom plate 1, the movable grinding block 21, the water storage tank 24, the miniature The water pump 25, water pipe 26, three-way valve 27, connecting pipe 28 and detection device are provided with an installation groove 6 for fixing the tail of the glass needle to be broken on the upper surface of the slider 3, and the installation groove 6 is a dovetail groove. In the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com