Hollow carbon microspheres and preparation method thereof

A carbon microsphere and hollow technology, applied in the field of hollow carbon microspheres and their preparation, can solve the problems of high equipment investment requirements, difficult control, and great impact on quality, and achieve easy large-scale application, high-efficiency utilization, and preparation methods simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

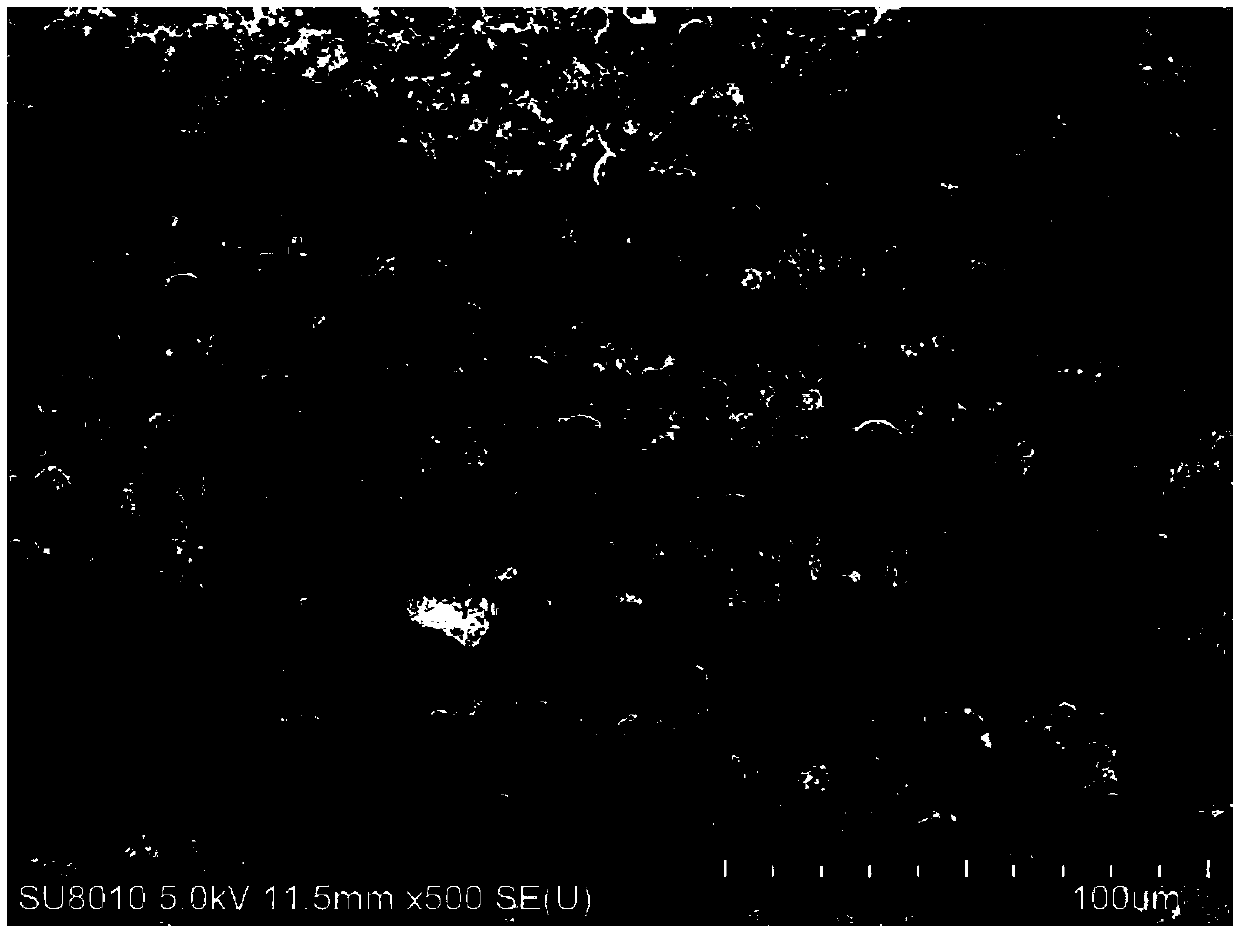

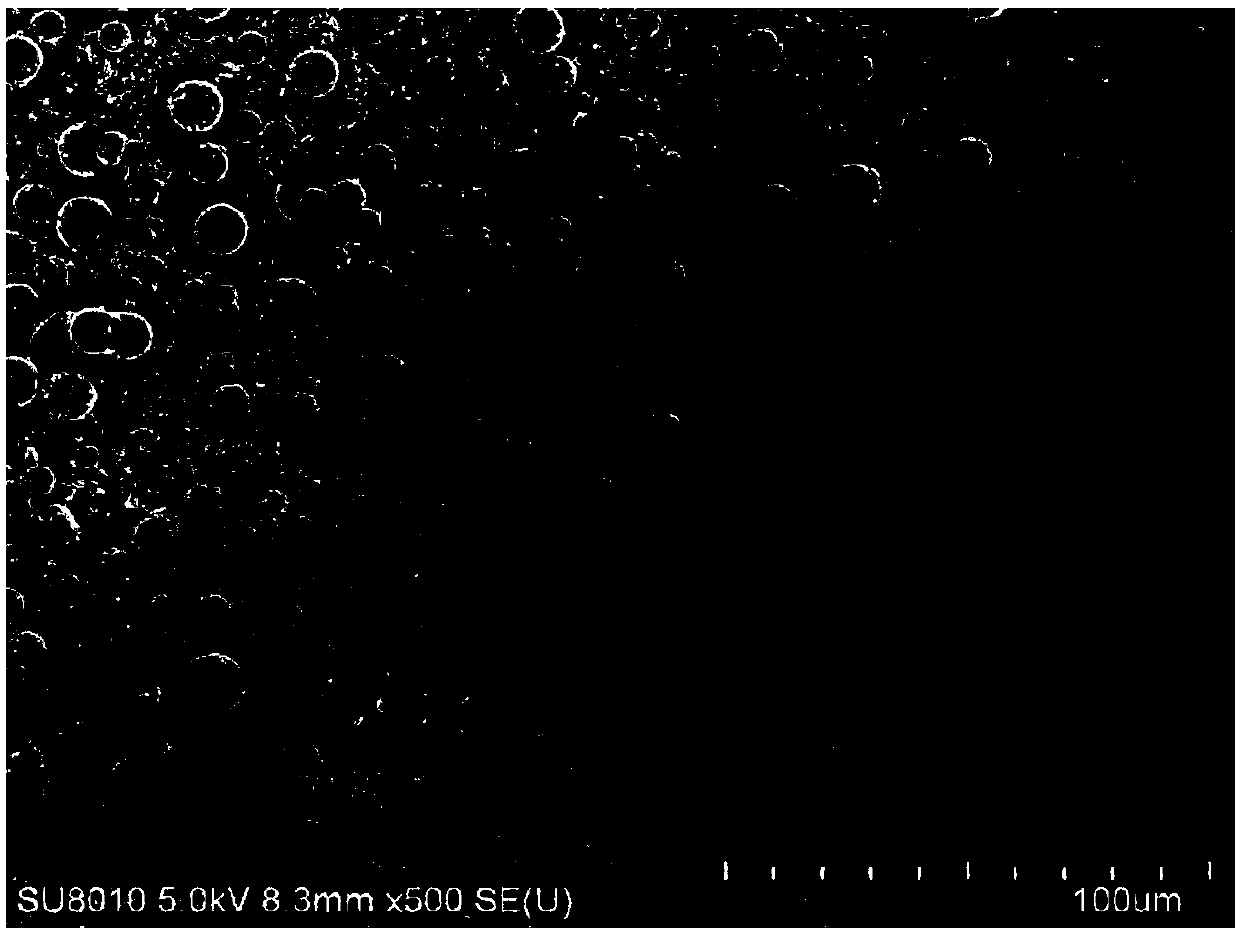

Image

Examples

Embodiment 1

[0090] The preparation method of the hollow carbon microspheres of the present embodiment is as follows:

[0091] 1) Use mixed light hydrocarbons as the extraction solvent, the composition is isobutane and n-butane, the mass ratio is 1:1, according to calculation, its critical temperature is 143.45°C, after the catalytic cracking oil slurry is mixed with the extraction solvent, it is extracted from the middle of the extraction tower Feed and the feed temperature is 90°C, the mass ratio of agent to oil is 4:1, the mixed solvent and catalytic cracking oil slurry are subjected to supercritical extraction in the extraction tower, and the formed extracted oil phase is sent out from the top of the extraction tower and enters the separation tower. The raffinate phase is discharged from the bottom of the extraction tower as recovery;

[0092] 2) After extracting the oil phase and performing supercritical desolventization treatment, the extracted components are obtained;

[0093] 3) a...

Embodiment 2

[0105] The preparation method of the hollow carbon microspheres of the present embodiment is as follows:

[0106] 1) Using n-pentane as the extraction solvent, its critical temperature is 196.6°C, coal tar is mixed with the extraction solvent and fed from the middle of the extraction tower at a temperature of 150°C, the mass ratio of solvent to oil is 3:1, and n-pentane Carry out supercritical extraction and separation with coal tar in the extraction tower, the formed extracted oil phase is sent from the top of the extraction tower and enters the separation tower, and the raffinate phase is discharged from the bottom of the extraction tower for recovery;

[0107] 2) The first separation temperature of the separation tower (the first separation tower) is 150°C, the temperature of the second separation stage (the second separation tower) is 170°C, and the separation pressure is 5MPa to obtain the extracted light oil phase and the extracted heavy oil phase respectively;

[0108] ...

Embodiment 3

[0121] The preparation method of the hollow carbon microspheres of the present embodiment is as follows:

[0122] 1) Using n-pentane as the extraction solvent, its critical temperature is 196.6°C, coal tar is mixed with the extraction solvent and fed from the middle of the extraction tower at a temperature of 150°C, the mass ratio of solvent to oil is 4:1, and n-pentane Carry out supercritical extraction with coal tar in the extraction tower, the formed extracted oil phase is sent from the top of the extraction tower and enters the separation tower, and the raffinate phase is discharged from the bottom of the extraction tower for recovery;

[0123] 2) The first separation temperature of the separation tower (the first separation tower) is 150°C, the temperature of the second separation stage (the second separation tower) is 170°C, and the separation pressure is 5MPa to obtain the extracted light oil phase and the extracted heavy oil phase respectively;

[0124] After performin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com