Single-crystal ternary cathode material containing microelements

A positive electrode material and trace element technology, which is applied in the direction of polycrystalline material growth, single crystal growth, single crystal growth, etc., can solve the problems of particle pulverization, less side reactions, and large primary particles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

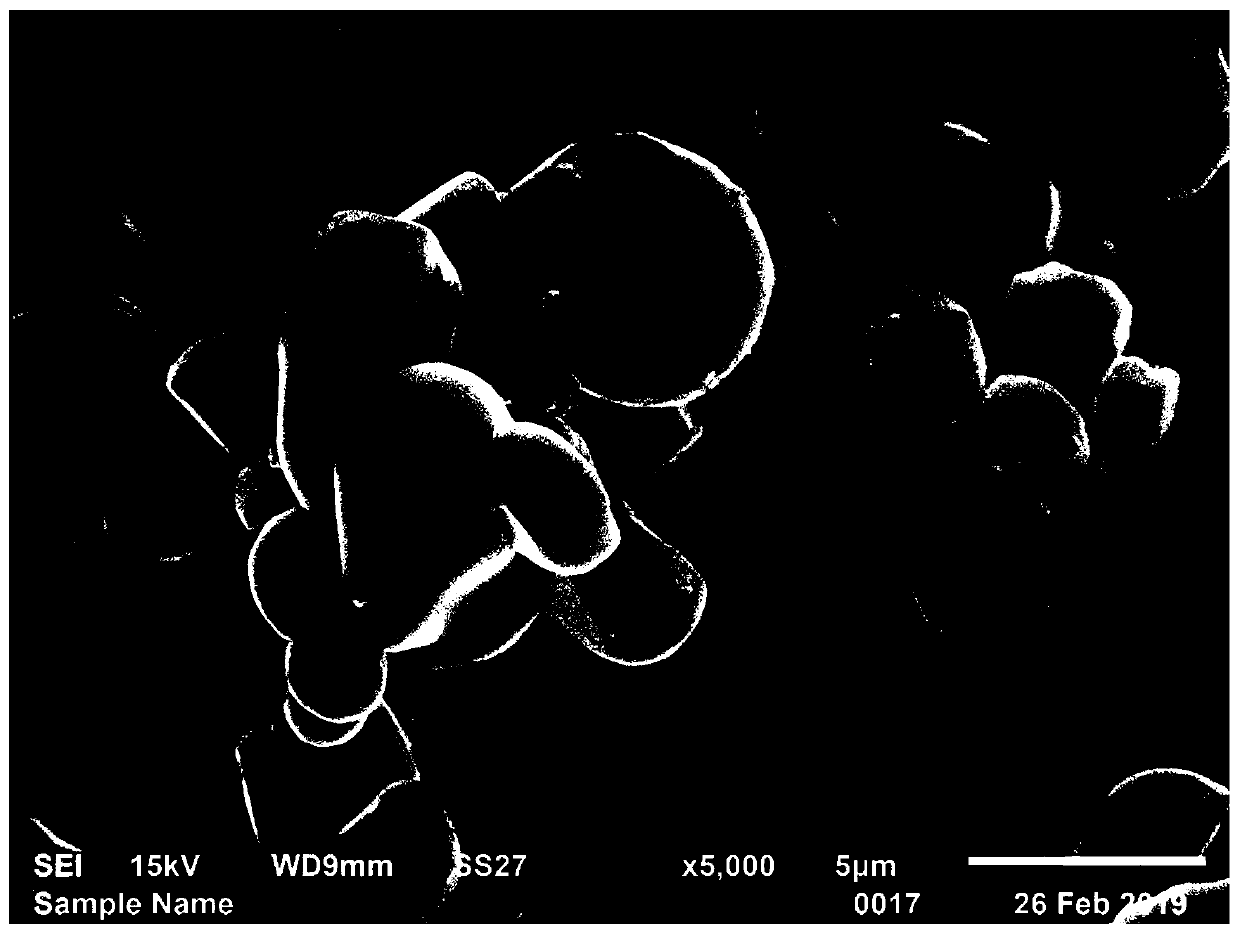

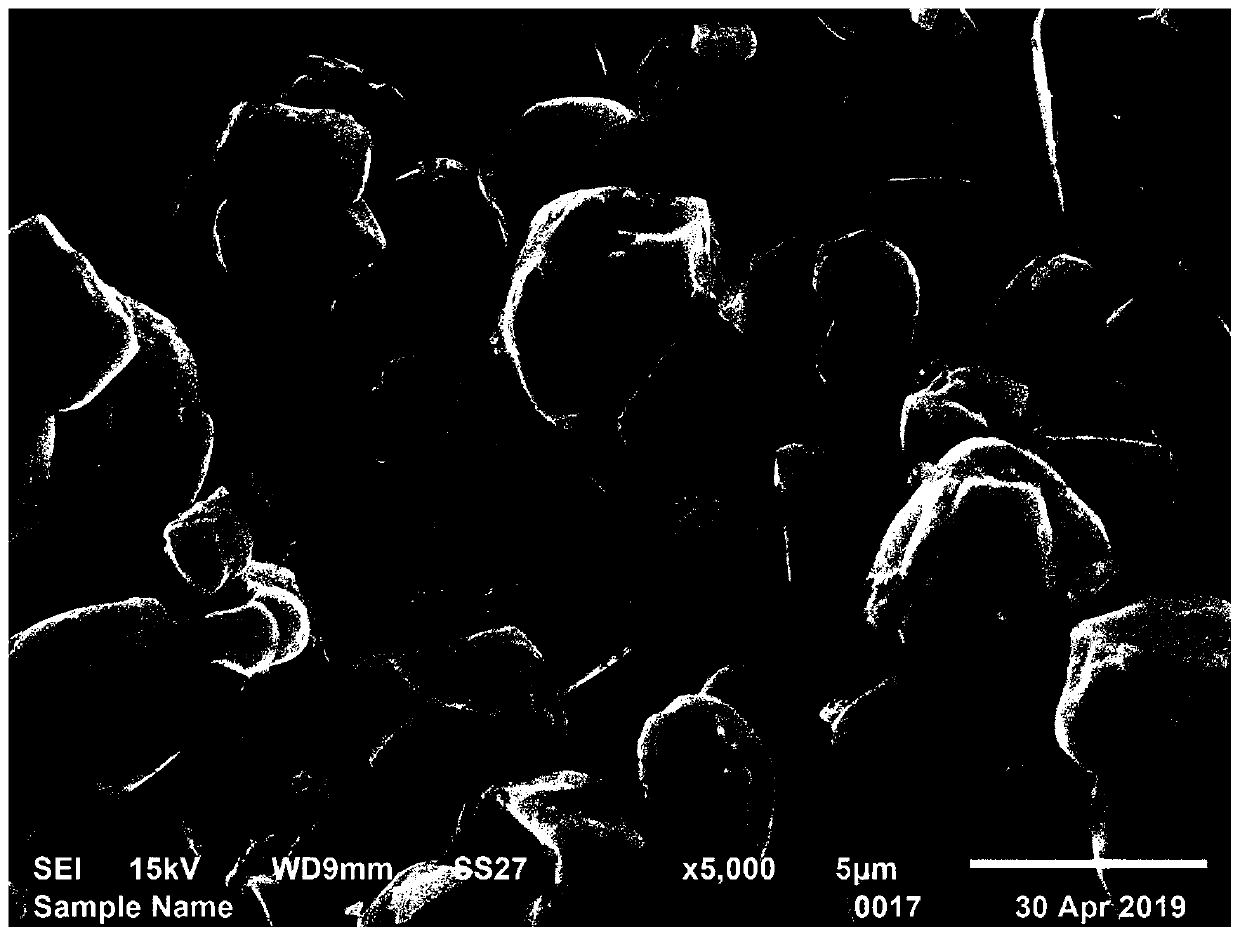

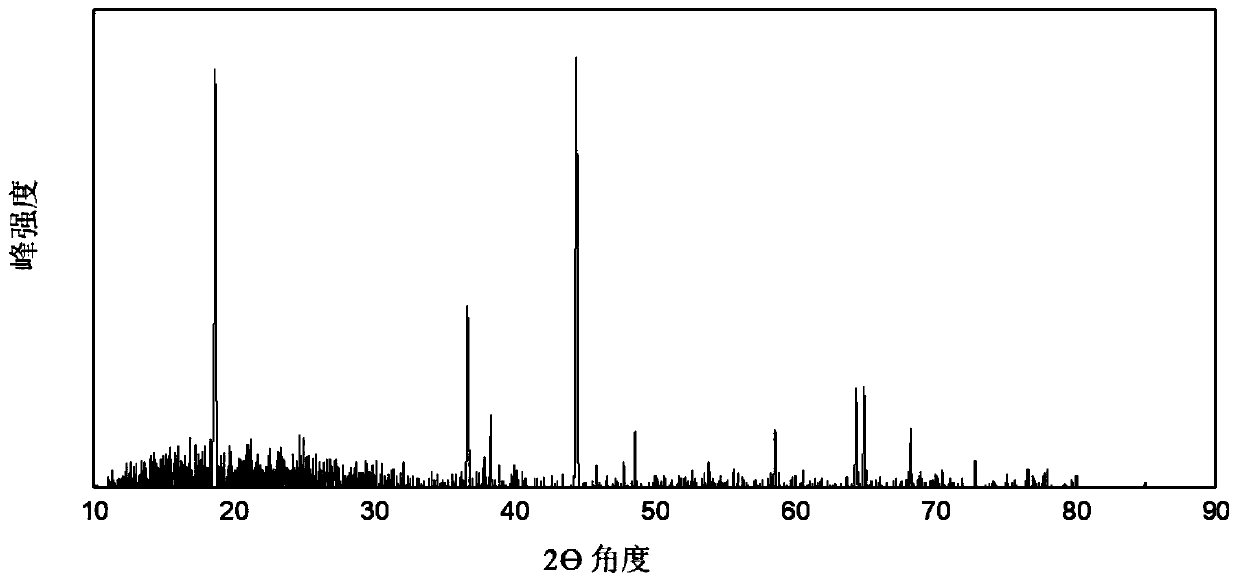

[0032] Single-crystal nickel-cobalt-manganese cathode material LiNi compound doped and coated with trace elements 5 co 2 mn 3 (MgAl) z o 2 The preparation method comprises the following steps:

[0033] 1) Preparation of magnesium-doped single crystal ternary cathode material C: the 5 μm523 ternary precursor Ni 5 co 2 mn 3 (OH) 2 , Lithium carbonate and basic magnesium carbonate are mixed, and the ball mill is used for 8 hours to mix evenly, and sintered to obtain a magnesium-doped single crystal 523 ternary positive electrode material C; wherein lithium carbonate and the ternary precursor Ni 5 co 2 mn 3 (OH) 2 The molar ratio is 1.1, the mass of basic magnesium carbonate is 0.5% of the mass of the precursor, the sintering atmosphere is 40% oxygen, and the sintering temperature is 980°C*17h;

[0034] 2) Take 200g of single crystal C, add the corresponding aluminum phosphate to the single crystal C according to 2 / 1000, 5 / 1000, and 10 / 1000 of the mass of the single cry...

Embodiment 2

[0036] Single-crystal nickel-cobalt-manganese cathode material LiNi compound doped and coated with trace elements 6 co 2 mn 2 (AlMn) z o 2 The preparation method comprises the following steps:

[0037] 1) Preparation of aluminum-doped single crystal ternary cathode material E: the 4 μm622 ternary precursor Ni 6 co 2 mn 2 (OH) 2 , Lithium Hydroxide and Aluminum Oxide, mixed with ball mill for 8 hours, and then sintered to obtain aluminum-doped single crystal 622 ternary positive electrode material E; Lithium Hydroxide and ternary precursor Ni 6 co 2 mn 2 (OH) 2 The molar ratio is 1.08, the mass of alumina is 0.3% of the mass of the precursor, the sintering atmosphere is 60% oxygen, and the sintering temperature is 940°C*10h;

[0038]2) Take 200g single crystal E, add the corresponding manganese phosphate to single crystal E according to one thousandth, three thousandths, and five thousandths of the mass of single crystal E, mix them with single crystal E, use a ball ...

Embodiment 3

[0040] Single-crystal nickel-cobalt-manganese cathode material LiNi compound doped and coated with trace elements 7 co 1.5 mn 1.5 (YZr) z o 2 The preparation method comprises the following steps:

[0041] 1) Preparation of aluminum-doped single crystal ternary cathode material G: the 5 μm 71515 ternary precursor Ni 7 co 1.5 mn 1.5 (OH) 2 , lithium hydroxide and yttrium oxide were mixed, and mixed evenly by ball milling for 8 hours, and sintered to obtain yttrium-doped single crystal 71515 ternary positive electrode material G; wherein lithium hydroxide and ternary precursor Ni 7 co 1.5 mn 1.5 (OH) 2 The molar ratio is 1.09, the mass of yttrium oxide is 0.1% of the mass of the precursor, the sintering atmosphere is 80% oxygen, and the sintering temperature is 870°C*15h;

[0042] 2) Take 200g of single crystal G, take 2 / 1000, 5 / 1000, and 8 / 1000 of the mass of single crystal G, respectively take the corresponding zirconium phosphate and add it to single crystal E to mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com