A catalyst preparation method for regulating methane and carbon monoxide selectivity and its application

A technology for catalysts and carbon dioxide catalysis, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of complex synthesis process and achieve simple preparation process and high activity The effect of small attenuation and low nickel content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

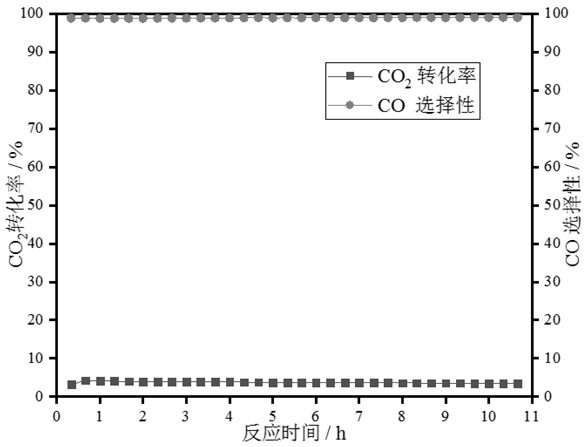

Embodiment 1

[0032] A preparation method of a catalyst, which specifically comprises the steps:

[0033] 1) Prepared by deposition-precipitation method: 0.3287 g of nickel acetate tetrahydrate was added to 70 mL of butanediol, and sonicated for 0.5 h to obtain a homogeneous solution A with a concentration of 0.019 mol / L. Weigh 3 g of anatase, add 26.5 mL of 0.1 mol / L ammonia water to ultrasonic for 0.5 h to promote uniform dispersion to obtain system B (the concentration of anatase in system B is 1.4 mol / L); add solution A dropwise to the solution. In system B (the volume ratio of the two is A; B=2.6), stir for 1 hour after the dropwise addition, and then age at room temperature for 24 hours. After the aging, wash with 25% ethanol solution to neutrality;

[0034] 2) Dry in an oven at 70°C for 24h, then roast in a muffle furnace at 450°C for 3h, and cool down to obtain NiO / TiO 2 ;

[0035] 3) Before the catalyst is used, in a volume ratio of 3:2 Ar and H 2 Reduction was carried out at 45...

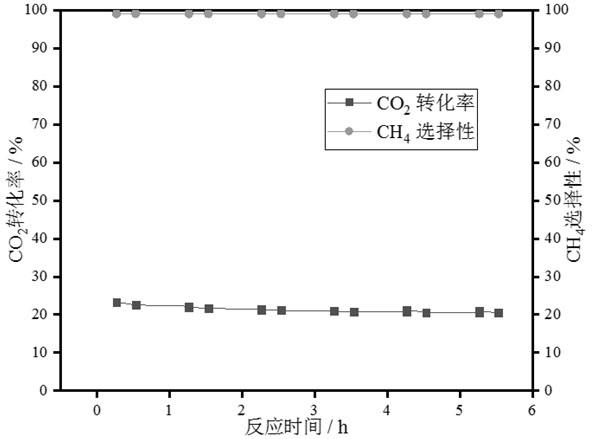

Embodiment 2

[0037] A preparation method of a catalyst, which specifically comprises the steps:

[0038]1) Prepared by deposition-precipitation method: 0.3287 g of nickel acetate tetrahydrate was added to 70 mL of butanediol, and sonicated for 0.5 h to obtain a homogeneous solution A with a concentration of 0.019 mol / L. Weigh 3 g of anatase, add 26.5 mL of 0.1 mol / L sodium carbonate solution, and sonicate for 0.5 h to promote uniform dispersion to obtain system B (the concentration of anatase in system B is 1.4 mol / L); Add dropwise to system B (the volume ratio of the two is A; B=2.6), stir for 1 hour after the dropwise addition, then age at room temperature for 24 hours, and wash with 25% ethanol solution by volume to neutrality after aging;

[0039] 2) Dry in an oven at 70°C for 24h, then roast in a muffle furnace at 450°C for 3h, and cool down to obtain NiO / TiO 2 ;

[0040] 3) Before the catalyst is used, in Ar and H 2 (3:2, v / v) was reduced at 450 °C for 4 h in a mixed atmosphere to...

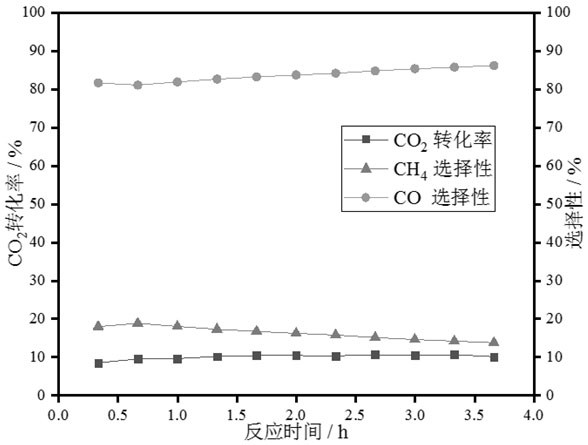

Embodiment 3

[0042] A preparation method of a catalyst, which specifically comprises the steps:

[0043] 1) Prepared by deposition-precipitation method: 0.7824 g of nickel nitrate hexahydrate in 70 mL of ethylene glycol was sonicated for 0.5 h to obtain a homogeneous solution A with a concentration of 0.038 mol / L. Weigh 3 g of titanium dioxide P25, add 53.8 mL of 0.2 mol / L ammonia water, and sonicate for 0.5 h to promote uniform dispersion to obtain system B (the P25 concentration in system B is 0.7 mol / L); solution A is added dropwise to system B Medium (the volume ratio of the two is A; B=1.3); after the dropwise addition, stir for 2 hours, then age at room temperature for 12 hours, and wash with 50% ethanol solution by volume after the aging to neutrality;

[0044] 2) Dry in an oven at 80°C for 12h, then roast in a muffle furnace at 400°C for 3h, and cool down to obtain NiO / TiO 2 ;

[0045] 3) Before the catalyst is used, in Ar and H 2 (3:2, v / v) was reduced at 400 °C for 4 h in a mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com