Preparation method of mineral source nitro fulvic acid

A technology of nitrofulvic acid and minerals, which is applied in fertilizer mixtures, organic fertilizers, nitrogen fertilizers, etc., can solve the problems of low fulvic acid concentration, long process, and high energy consumption, and achieve high fulvic acid content, short process, The effect of less investment in equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

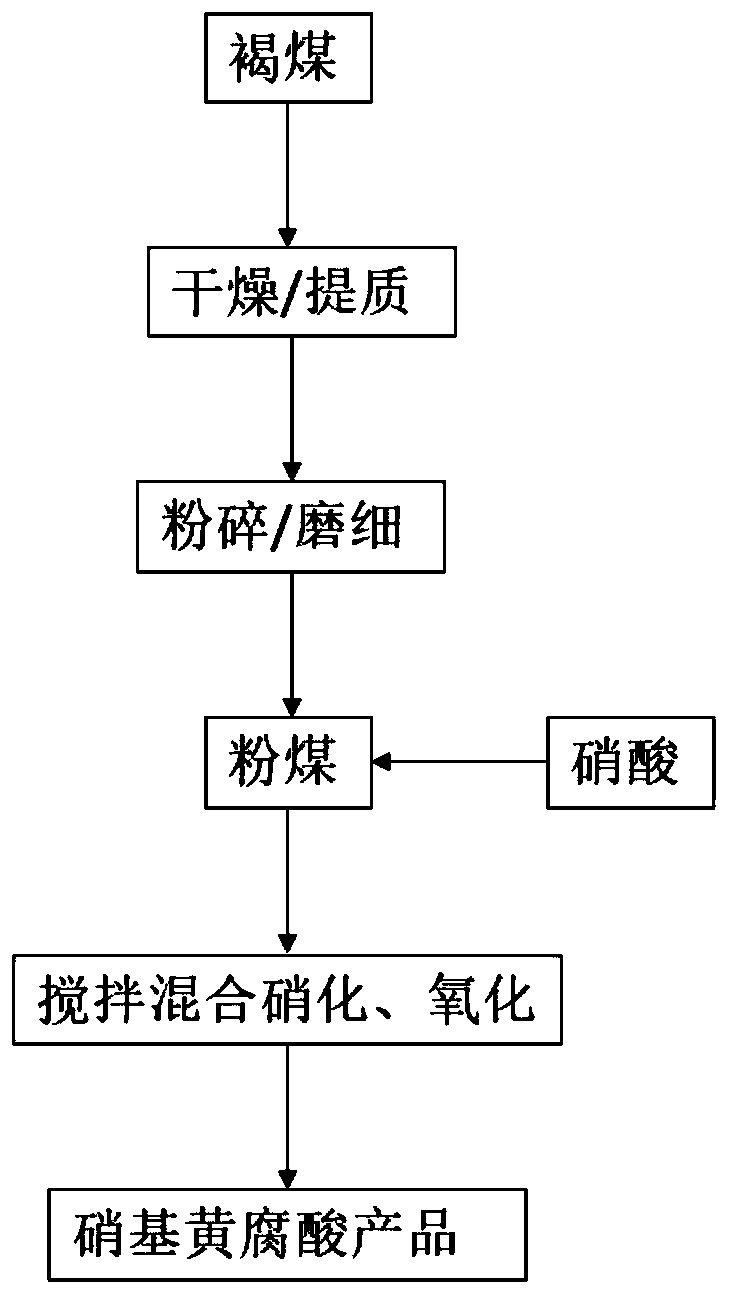

Method used

Image

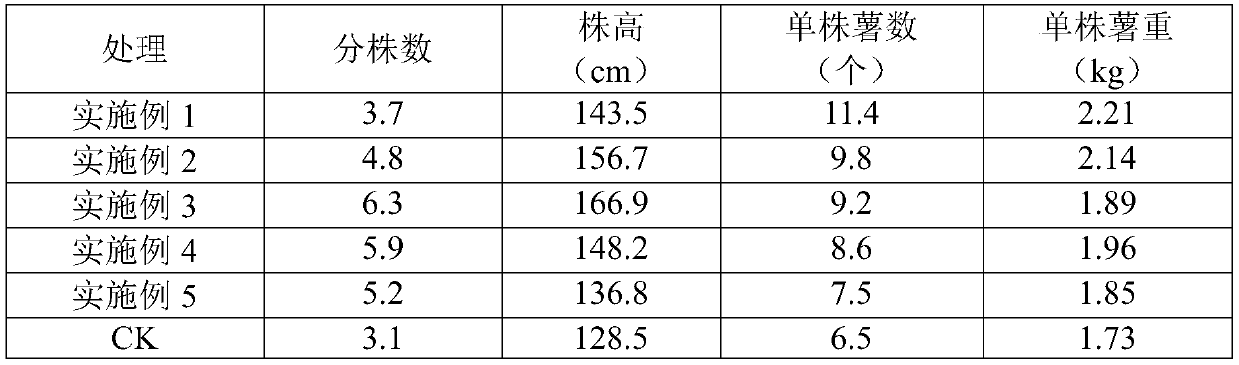

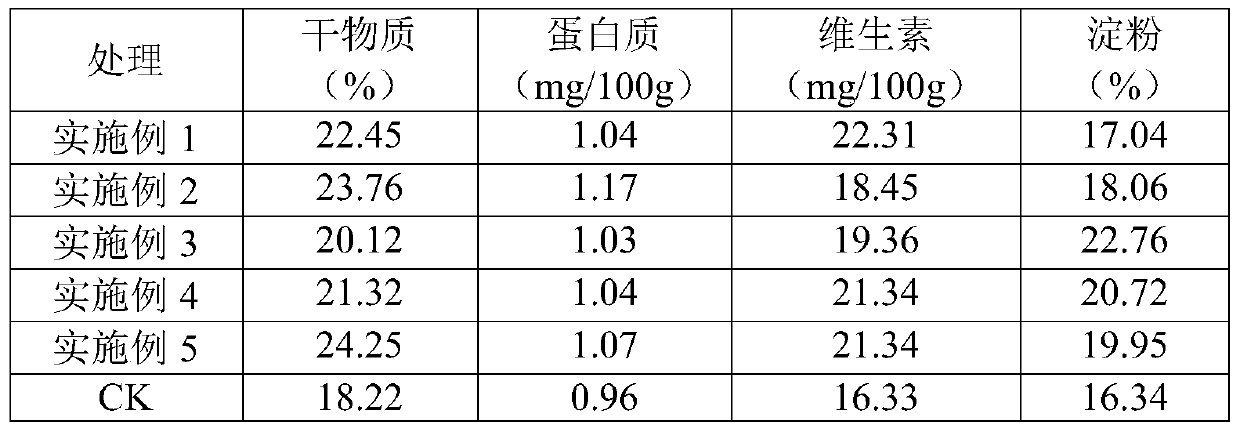

Examples

Embodiment 1

[0020] Raw material: lignite, the carbon content of raw coal is 57.22%, the total humic acid is more than 45%, the moisture is less than 20%, the ash content is 21.94%, and the volatile content is 20%. Industrial nitric acid: concentration 45%. Coal acid mass ratio: 1:0.5.

[0021] Preparation method: Dry the newly mined lignite ore with hot air at 150°C until the water content is 15-25%, crush the dried lignite block through a crusher, and then crush it through a Raymond mill. The particle size of the lignite powder is 60 mesh. The separated lignite powder and nitric acid solution were stirred and mixed for 50 minutes to obtain the product.

[0022] Test results: the content of fulvic acid in the product is 12.6%, and the water content is 14.1%.

Embodiment 2

[0024] Raw material: lignite, the carbon content of raw coal is 55.34%, the total humic acid is more than 45%, the moisture is less than 20%, the ash content is 21.94%, and the volatile content is 20%. Industrial nitric acid: concentration 50%. Coal acid mass ratio: 1:0.7.

[0025] Preparation method: Dry the newly mined lignite ore with hot air at 120°C until the water content is 15-25%, crush the dried lignite block through a crusher, and then crush it through a Raymond mill. The particle size of the lignite powder is 70 mesh. The sieved lignite powder and nitric acid solution were stirred and mixed for 60 minutes to obtain the product.

[0026] Test results: the content of fulvic acid in the product is 14.2%, and the water content is 11.5%.

Embodiment 3

[0028] Raw material: lignite, the carbon content of raw coal is 60.80%, the total humic acid is more than 45%, the moisture is less than 20%, the ash content is 21.94%, and the volatile content is 20%. Industrial nitric acid: concentration 53%. Coal acid mass ratio: 1:0.65.

[0029] Preparation method: Dry the newly mined lignite ore with hot air at 130°C until the moisture content is 15-25%, crush the dried lignite block through a crusher, and then crush it through a Raymond mill. The particle size of the lignite powder is 60 mesh. The sieved lignite powder and nitric acid solution were stirred and mixed for 70 minutes to obtain the product.

[0030] Test results: the content of fulvic acid in the product is 13.5%, and the water content is 9.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com