Industrial production method of vat dark blue BO

A production method, deep blue technology, applied in chemical instruments and methods, organic chemistry, carbon-based compound preparation, etc., can solve the problems of high raw material consumption, high production cost, environmental pollution, etc., and achieve high yield, good product quality, Environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

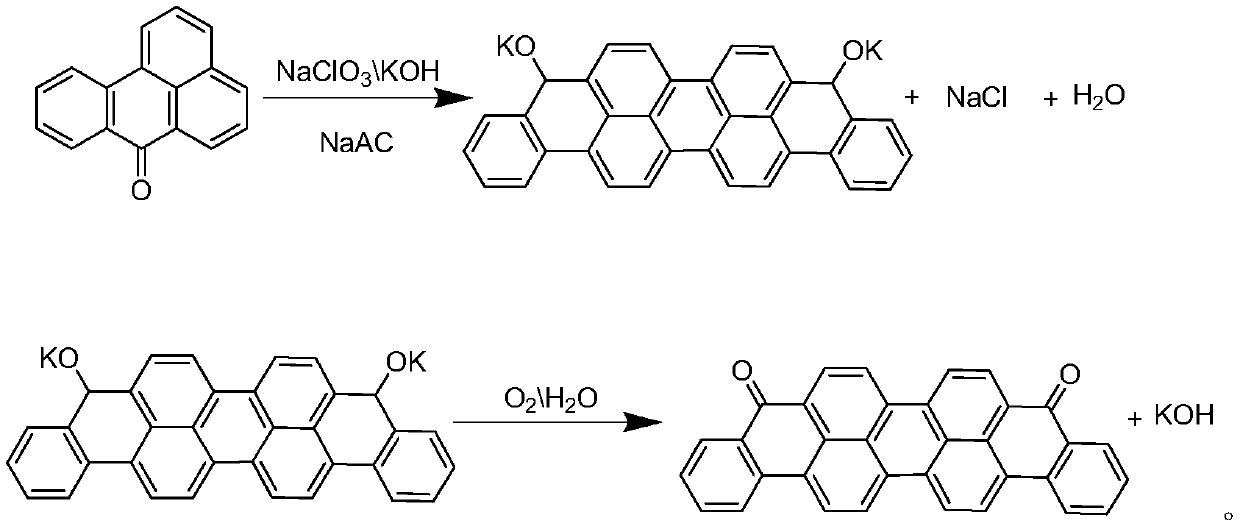

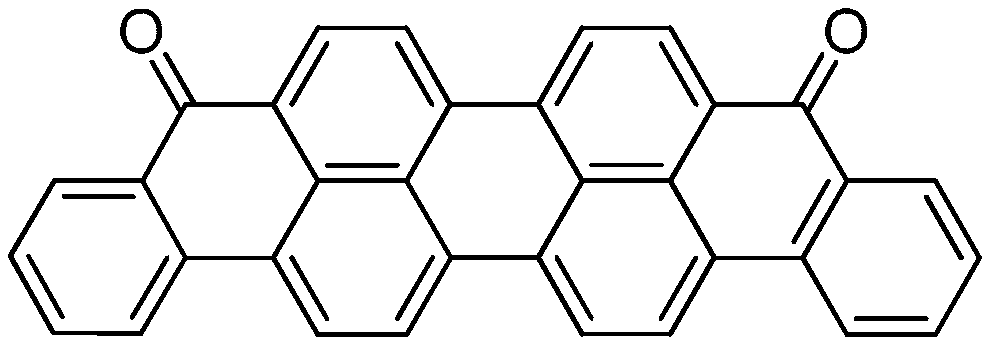

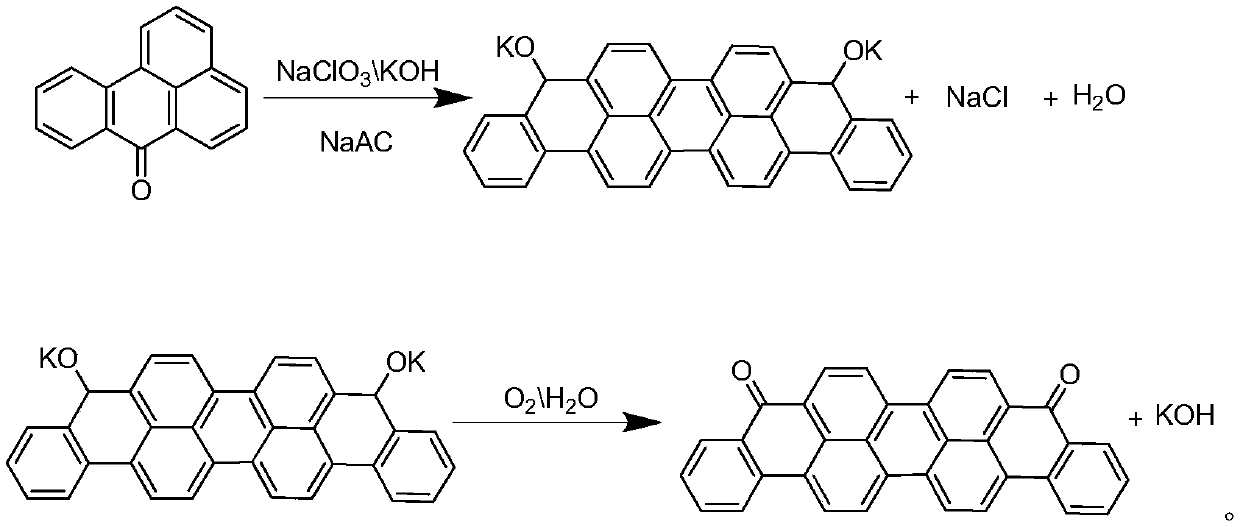

Method used

Image

Examples

Embodiment 1

[0031] Add 400L PEG-400 from the metering tank, start stirring, put 72kg of anhydrous sodium acetate (molecular weight 82, 878mol) and 520kg potassium hydroxide (molecular weight 56, 9.29kmol) into a 2000L condensation pot at a time under stirring conditions, and use less than 0.3Mpa Steam is heated to 130-135°C to fully dissolve the raw materials; under a stable temperature of 120-135°C, use 0.01-0.02Mpa nitrogen for protection; for the first time, add about 0.75 kg (mass. Concentration is 77%), after 5 minutes, add 7.5 kilograms of benzothrone, after the temperature is stable (about 5 minutes), add sodium hypochlorite for the second time, add benzoxantrone for the second time after 5 minutes, add alternately, thereafter every The second feeding must wait for the temperature to fall back to 120-135°C before continuing to add 0.75kg of sodium chlorate each time, and the time interval between two feedings of the same material is more than 10 minutes. The whole batch of materials...

Embodiment 2

[0035] Add 700L of the concentrated mother liquor obtained in Example 1 from the metering tank, add 80L PEG-400 in addition, start stirring, and mix 14.4kg anhydrous sodium acetate (molecular weight 82, 176mol), 104kg potassium hydroxide (molecular weight 56, 1.86mol) under stirring condition kmol) into a 2000L condensation pot at a time, heat up to 130-135°C with less than 0.3Mpa steam to fully dissolve the raw materials; under a stable temperature of 120-135°C, use 0.01-0.02Mpa nitrogen for protection; the first time to add About 0.75 kilograms of sodium chlorate aqueous solution configured (mass concentration is 77%), after 5 minutes, add 7.5 kilograms of benzoantrone, after the temperature is stable (about 5 minutes), add the second sodium hypochlorite, and then add the second sodium hypochlorite after 5 minutes Secondary benzoanthrone, add alternately, and after that, the temperature must drop to 120-135°C before continuing to add 0.75kg of sodium chlorate each time, and t...

Embodiment 3

[0040] Add 670L tetraethylene glycol from the metering tank, start stirring, and put 144kg anhydrous sodium acetate (molecular weight 82, 1.76kmol) and 183kg potassium hydroxide (molecular weight 56, 3.26kmol) into a 2000L condensation pot once under stirring conditions, and use less than 0.3 Mpa steam is heated to 130-135°C to fully dissolve the raw materials; under the stable condition of 120-135°C, protect with 0.01-0.02Mpa nitrogen; add about 1.16 kg of sodium chlorate aqueous solution for the first time ( Mass concentration is 60%), add 7.5 kilograms of benzothrone after 5 minutes, add the second sodium hypochlorite again after the temperature is stable (about 5 minutes), add the second benzoxantrone after 5 minutes, add alternately, thereafter Add 0.75kg of sodium chlorate each time, and the time interval between two feedings of the same material is more than 10 minutes. The whole batch of materials is added in about 50 times. The whole feeding process takes about For 7....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com