Alloy steel and preparation method and application thereof

A technology of alloy steel and purpose, applied in the field of metallurgy, can solve the problems of high price, high production cost, low performance, etc., and achieve the effects of low cost, cost control, and content reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0092] This embodiment provides a kind of alloy steel, described alloy steel is according to component mass fraction:

[0093]Carbon 0.27%, silicon 0.24%, manganese 1.28%, phosphorus 0.005%, sulfur 0.002%, chromium 1.42%, niobium 0.055%, molybdenum 0.14%, the balance is iron and unavoidable impurities.

[0094] Present embodiment also provides a kind of preparation method of this alloy steel, and its specific method is:

[0095] (1) After mixing the raw materials of each element in the formula amount, smelting and casting are carried out to obtain an ingot.

[0096] (2) Forging the ingot described in step (1) at an initial forging temperature of 1250° C. for 120 minutes, and forging at a final forging temperature of 955° C. to obtain a forged piece. The forged ingot has a mass of 50 kg, and its length, width and height are 300mm, 120mm and 120mm. The forging is forged together with the riser, the riser must be completely removed after forging, and there are no cracks, shrink...

Embodiment 2

[0109] The alloy steel provided in this example is the same as that in Example 1 in terms of component types and mass fractions of each component.

[0110] This embodiment also provides a method for preparing the alloy steel, which is the same as the method in embodiment 1 except that the tempering temperature in step (4) is 580°C.

[0111] The test results of the alloy steel provided in this example are shown in Table 1.

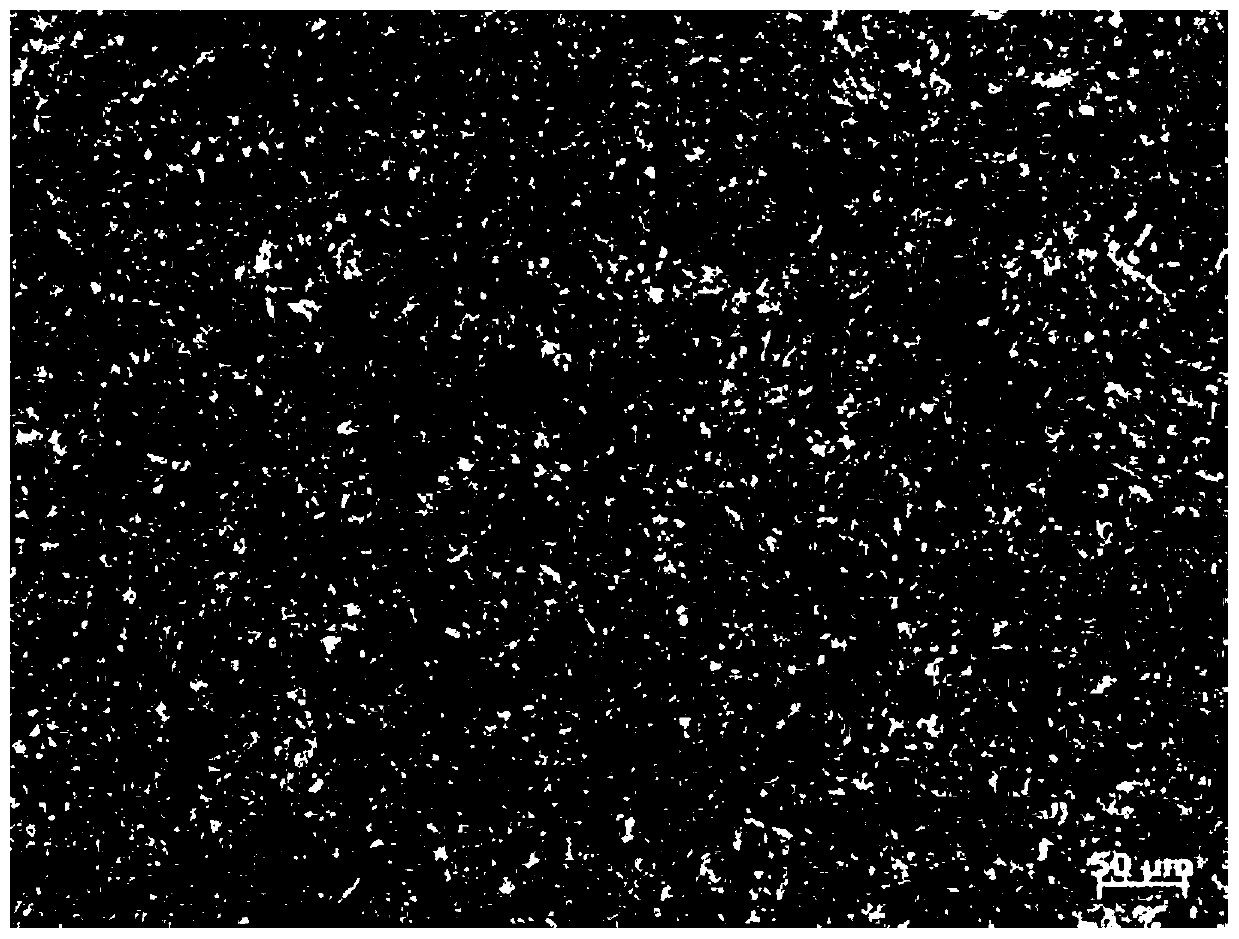

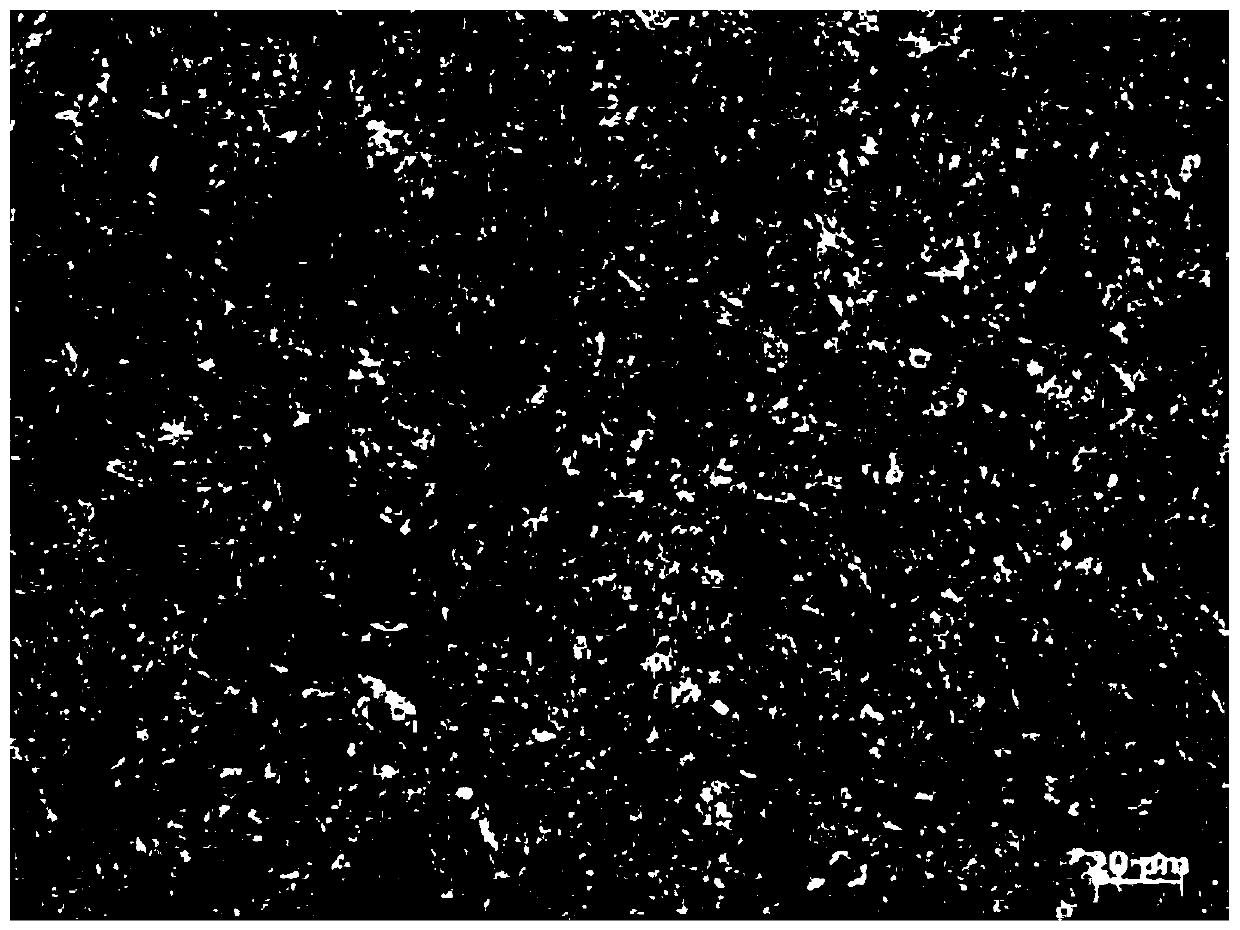

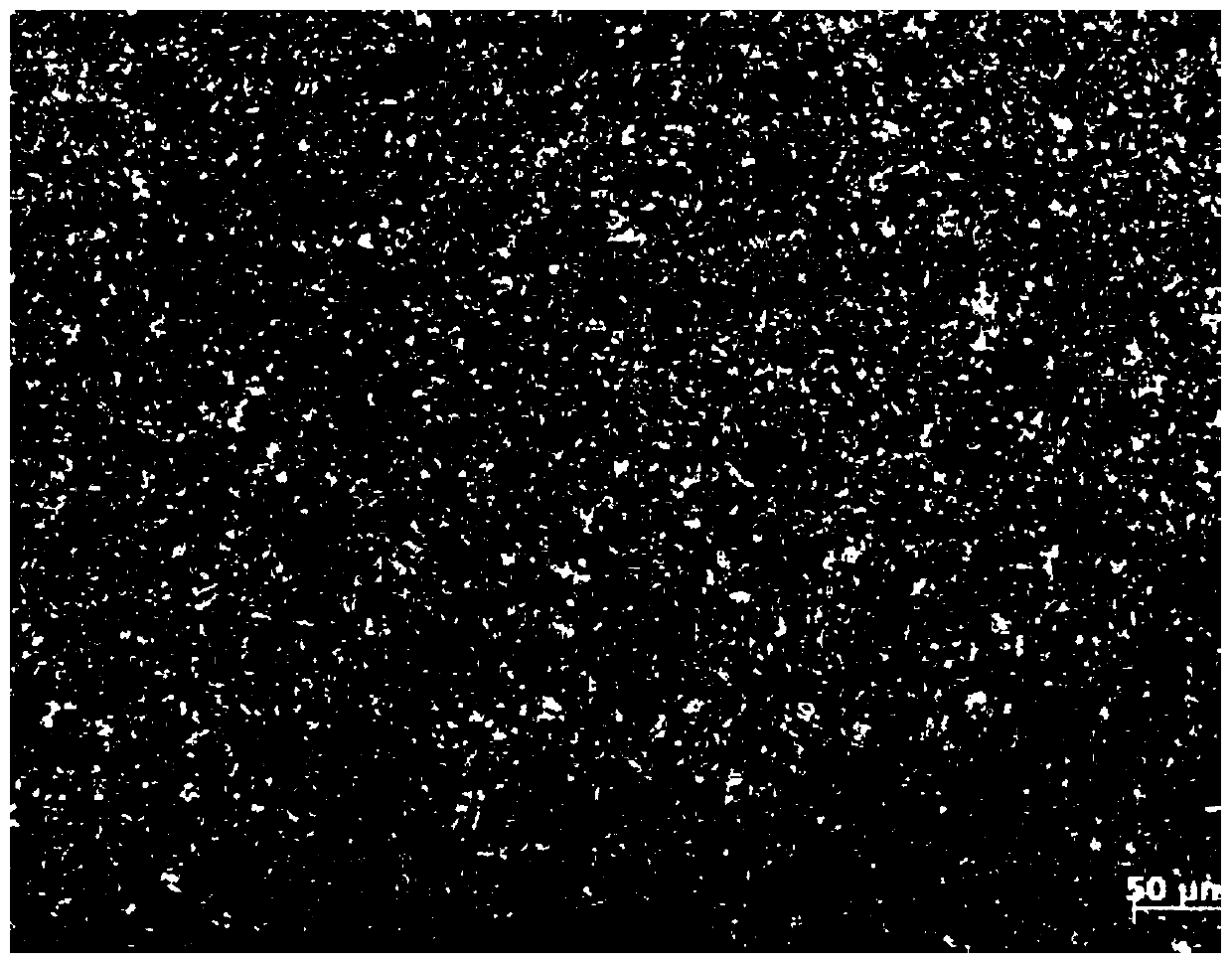

[0112] Figure 2a The 200x magnified scanning metallographic image of the center of the alloy steel prepared for this example shows that the matrix structure is: tempered sorbite with uniform distribution.

[0113] Figure 2b The 500x magnified scanning metallographic image of the center of the alloy steel prepared for the embodiment shows that the matrix structure is: tempered sorbite and the structure is evenly distributed.

[0114] Figure 2c The 200x enlarged scanning metallographic image of the outer wall of the alloy steel prepared for this exampl...

Embodiment 3

[0117] The alloy steel provided in this example is the same as that in Example 1 in terms of component types and mass fractions of each component.

[0118] This embodiment also provides a method for preparing the alloy steel, which is the same as the method in embodiment 1 except that the tempering temperature in step (4) is 600°C.

[0119] The test results of the alloy steel provided in this example are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com