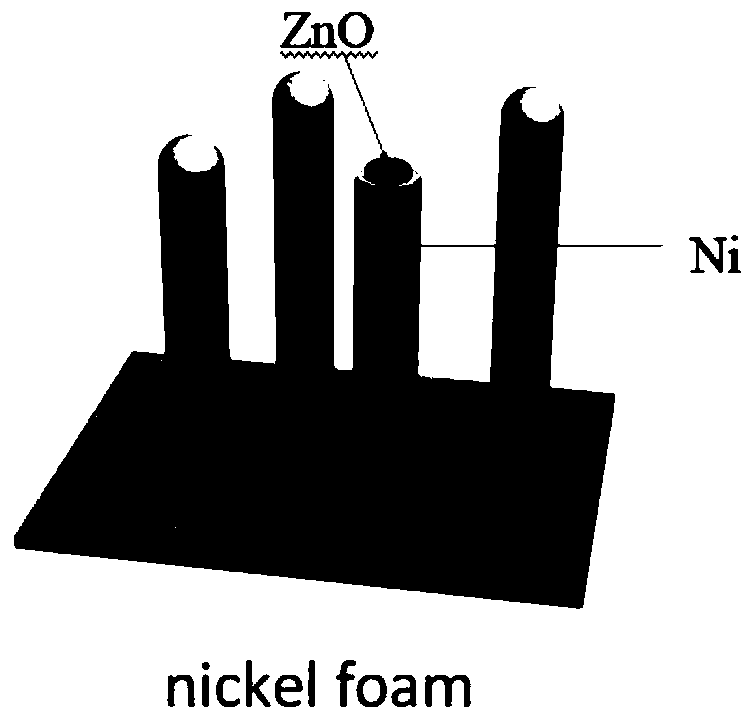

Foamed nickel self-supporting nickel nanotube super capacitor electrode material and preparation method thereof

A technology for supercapacitors and electrode materials, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double-layer capacitors. cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A kind of preparation method of nickel foam self-supporting nickel nanotube supercapacitor electrode material of the present embodiment, the steps are as follows:

[0048] (1) Foam nickel pretreatment

[0049] Prepare 3×4cm 2 The standard nickel foam is firstly soaked in 3mol / L hydrochloric acid and ultrasonically cleaned for 15 minutes, then ultrasonically cleaned in absolute ethanol for at least three times, and finally cleaned in deionized water for 15 minutes, and the nickel foam is taken out and placed in a drying oven for 8 hours at 70°C. spare.

[0050] (2) Preparation of zinc oxide nanorods

[0051] (i) Zinc oxide seed layer: Dissolve 0.01mol of zinc acetate in 100mL of anhydrous methanol, stir for 15min, then immerse the foamed nickel pretreated in step (1), continue ultrasonic stirring for 15min, then take it out and put it in a drying oven at 200 ℃ heating for 1h to obtain a zinc oxide seed layer with a thickness of about 5nm;

[0052] (ii) Zinc oxide gro...

Embodiment 2

[0063] A kind of preparation method of nickel foam self-supporting nickel nanotube supercapacitor electrode material of the present embodiment, the steps are as follows:

[0064] (1) Foam nickel pretreatment: 2.5×2.5cm 2 The standard nickel foam is first soaked in 3mol / L hydrochloric acid and ultrasonically cleaned for 15 minutes, then ultrasonically cleaned in absolute ethanol for at least three times, and finally cleaned in deionized water for 15 minutes, and the nickel foam is taken out and dried at 70°C for 8 hours for later use.

[0065] (2) Preparation of zinc oxide nanorods

[0066] With the mixed aqueous solution containing 0.01mol / L zinc nitrate and 0.05mol / L ammonium nitrate as the electrolyte, a three-electrode system is adopted, the foamed nickel after step (1) pretreatment is used as the working electrode, and the platinum electrode is used as the counter electrode. Mercury electrode to reference electrode, at 70°C, 12.5mA / cm 2 Electrodeposition at a constant te...

Embodiment 3

[0077] A kind of preparation method of nickel foam self-supporting nickel nanotube supercapacitor electrode material of the present embodiment, the steps are as follows:

[0078] (1) Foam nickel pretreatment: make 2×2cm 2 The standard nickel foam is first soaked in 3mol / L hydrochloric acid and ultrasonically cleaned for 15 minutes, then ultrasonically cleaned in absolute ethanol solution for at least three times, and finally cleaned in deionized water for 15 minutes, and finally the foam nickel is taken out and dried at 70°C for 8 hours. spare.

[0079] (2) Preparation of zinc oxide nanorods

[0080] (i) ZnO seed layer

[0081] Prepare 0.005mol / L zinc acetate absolute ethanol solution, stir until uniform, soak the nickel foam treated in step (1) for 30 minutes, and then anneal at 350°C in air for 20 minutes to obtain zinc oxide with a thickness of about 5nm seed layer.

[0082] (ii) step (i) is vertically placed in 0.025mol / L zinc nitrate, 0.025mol / L hexamethylenetetramine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com