Complex microbial agent used for ocean trash fish fermentation, and preparation method for enzymatic fish protein amino acid water-soluble fertilizer

A technology of compound microbial inoculants and compound enzyme preparations, applied in microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve problems such as soil compaction, improve soil ecology, optimize soil structure, and achieve dark green leaf color. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

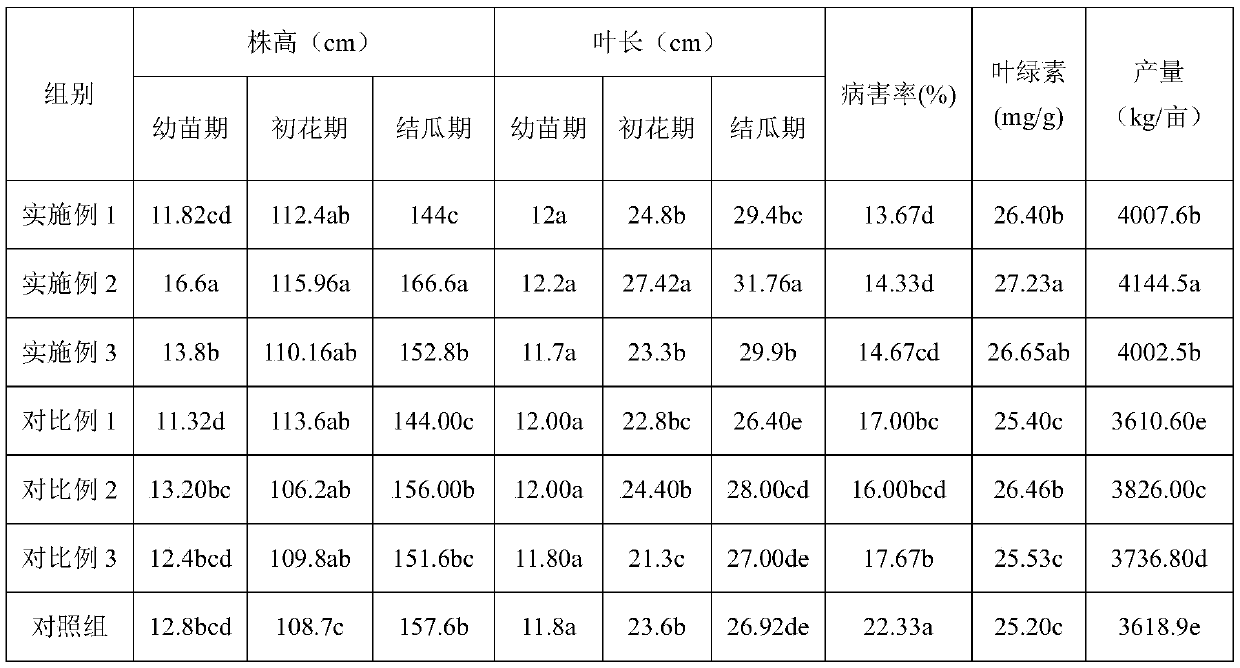

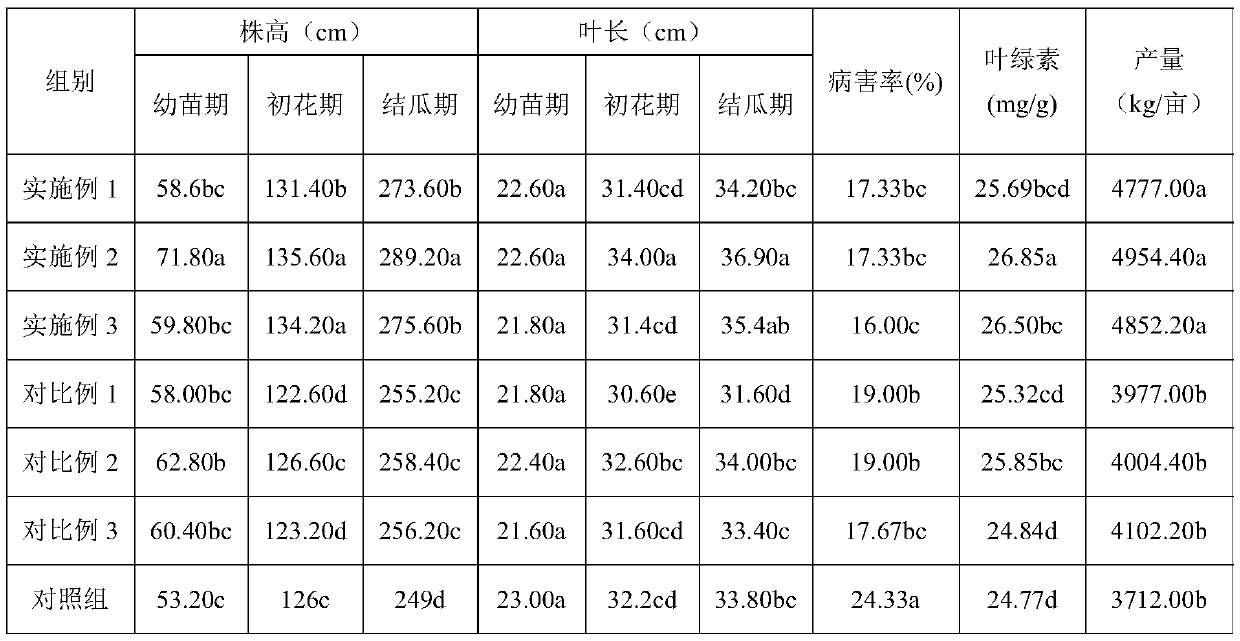

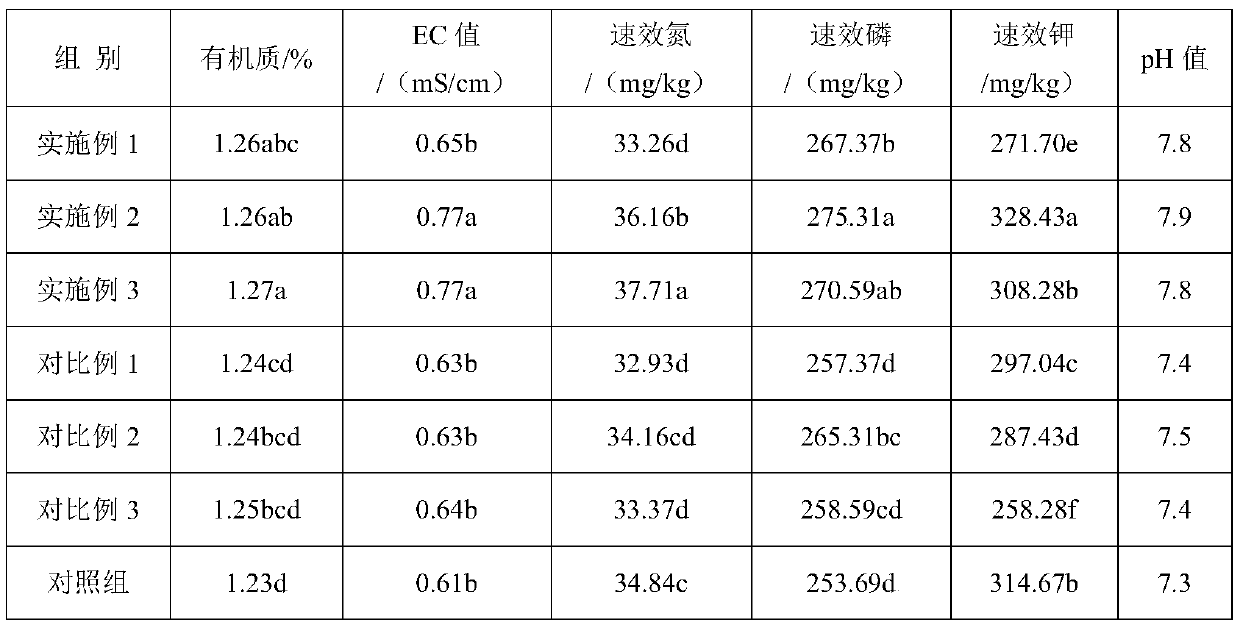

Examples

Embodiment 1

[0034] A method for preparing an enzymatically hydrolyzed fish protein amino acid water-soluble fertilizer, comprising the following steps:

[0035] (1) Stir the trash fish and the compound microbial agent evenly before transportation, perform pretreatment, and then pack them in plastic bags for normal temperature transportation;

[0036] (2) The pretreated marine trash fish is broken into 0.2cm fragments with a bone mud machine;

[0037] (3) Add water to the broken sea fish in a mass ratio of 1:2, and raise the temperature to 60°C, add a compound enzyme preparation for enzymolysis for 12 hours; then repeat this step to the enzyme obtained from the first enzymolysis Add the same amount of compound enzyme preparation to the hydrolyzate again to carry out the second enzymolysis to obtain the enzymolyzate;

[0038] (4) Send the enzymatic hydrolysis solution to the fermentation kettle and add the compound microbial bacterial agent, ferment at 25°C for 24 hours, fully stir during th...

Embodiment 2

[0044] A method for preparing an enzymatically hydrolyzed fish protein amino acid water-soluble fertilizer, comprising the following steps:

[0045] (1) Stir the trash fish and the compound microbial agent evenly before transportation, perform pretreatment, and then pack them in plastic bags for normal temperature transportation;

[0046] (2) The pretreated marine trash fish is broken into 0.2cm fragments with a bone mud machine;

[0047] (3) Add water to the crushed marine trash fish according to the mass ratio of 1:3.3, and raise the temperature to 65°C, add a compound enzyme preparation for enzymolysis for 8 hours; Add the same amount of compound enzyme preparation to the hydrolyzate again to carry out the second enzymolysis to obtain the enzymolyzate;

[0048] (4) Send the enzymolysis liquid to the fermentation tank and add the compound microbial bacterial agent, ferment at 40°C for 20 hours, fully stir during the fermentation process, and obtain fermented fish soluble pu...

Embodiment 3

[0054] A method for preparing an enzymatically hydrolyzed fish protein amino acid water-soluble fertilizer, comprising the following steps:

[0055] (1) Stir the trash fish and the compound microbial agent evenly before transportation, perform pretreatment, and then pack them in plastic bags for normal temperature transportation;

[0056] (2) The pretreated marine trash fish is broken into 0.2cm fragments with a bone mud machine;

[0057] (3) Add water to the broken sea fish in a mass ratio of 1:2.7, and heat up to 63°C, add a compound enzyme preparation for enzymolysis for 10 hours; Add the same amount of compound enzyme preparation to the hydrolyzate again to carry out the second enzymolysis to obtain the enzymolyzate;

[0058] (4) Send the enzymatic hydrolysis solution to the fermentation kettle and add the compound microbial bacterial agent, ferment at 25°C for 24 hours, fully stir during the fermentation process, and obtain fermented fish soluble pulp after the fermentat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com