Colorimetric-fluorescent fiber membrane for detecting hypochlorite ions, and preparation method thereof

A fluorescent fiber and hypochlorite technology, applied in fluorescence/phosphorescence, measuring devices, and material analysis through optical means, can solve expensive problems and achieve low detection limit, simple operation, and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

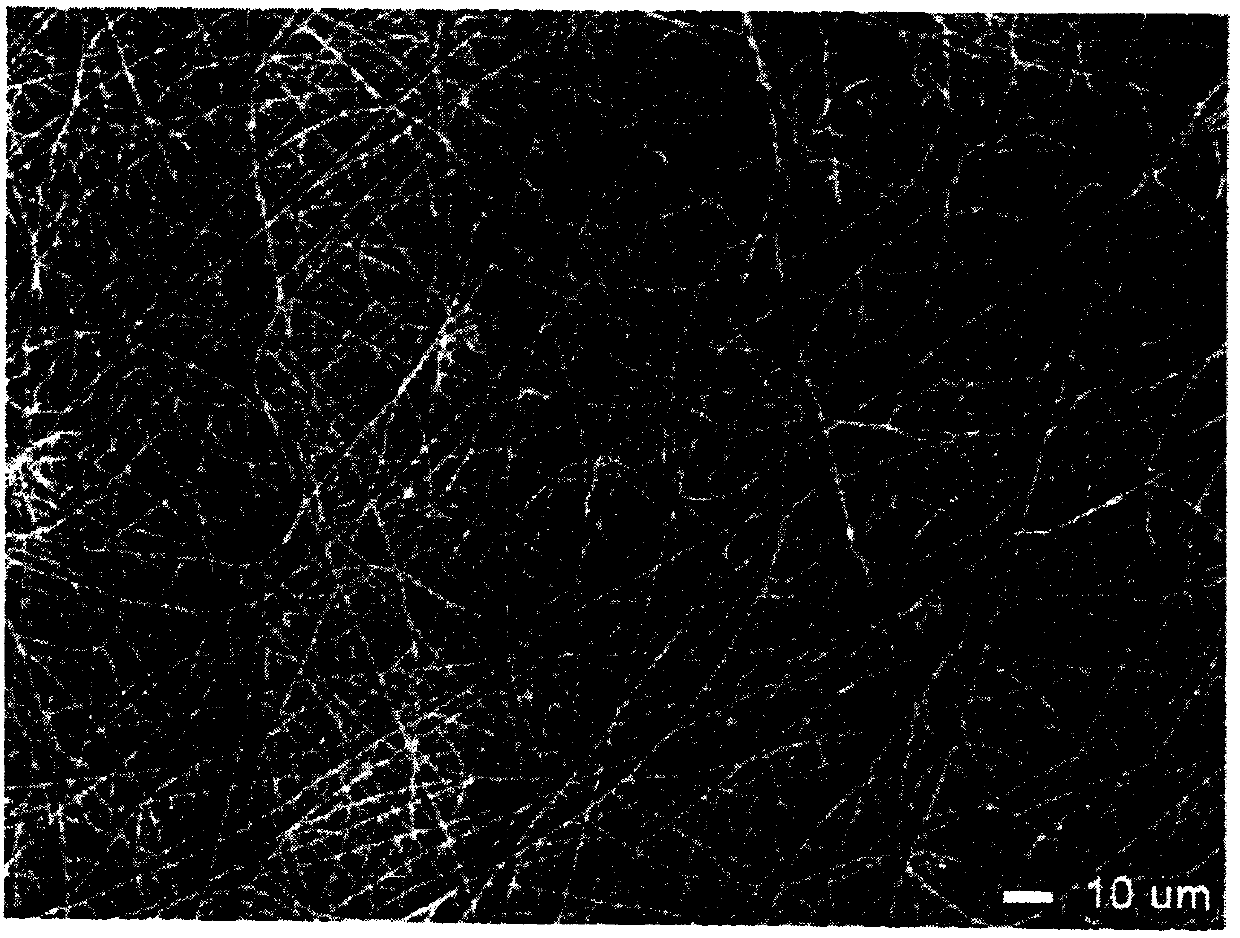

Image

Examples

Embodiment 1

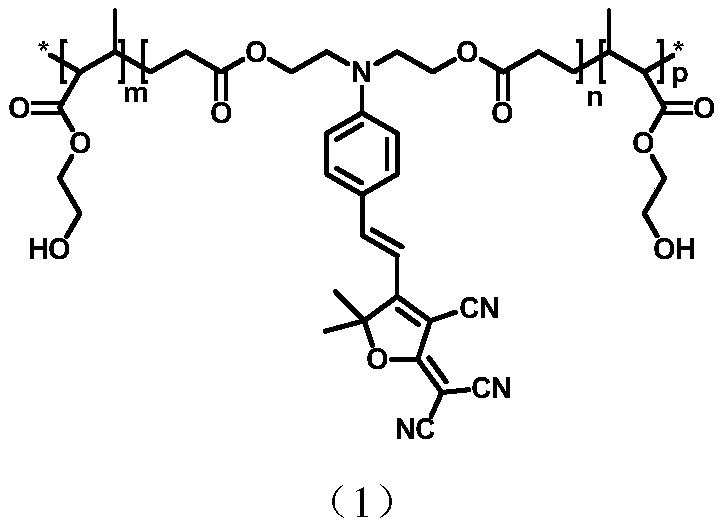

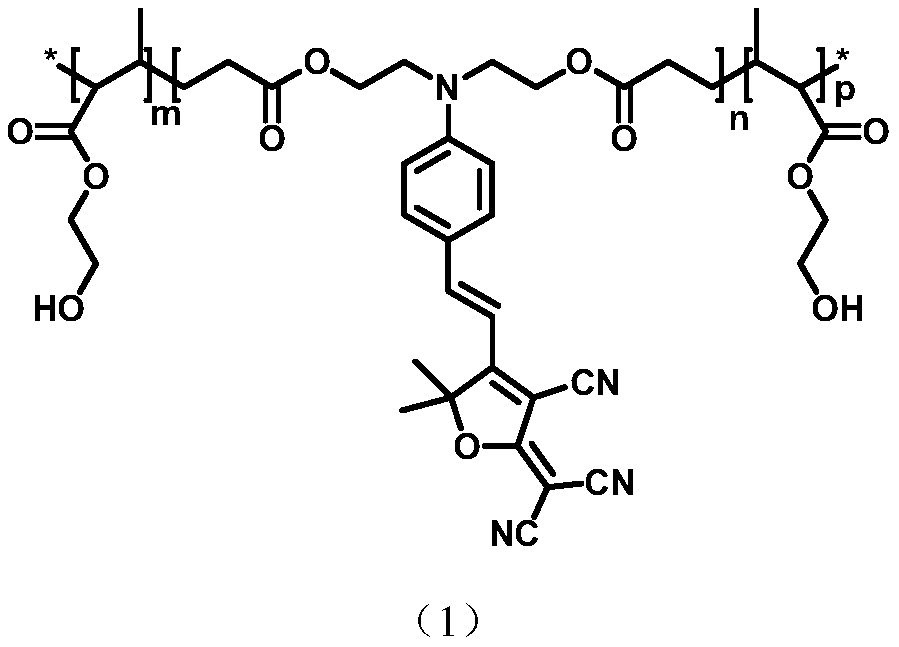

[0024] Preparation of modified poly(hydroxyethyl methacrylate):

[0025] a, 1mmol colorimetric-fluorescent probe molecule containing double bond ((E)-((4-(2-(4-cyano-5-(dicyanomethylene)-2,2-dimethyl -2,5-dihydrofuran-3-yl)vinyl)phenyl)azanediyl)bis(ethane-2,1-diyl)diacrylate) and 100mmol hydroxyethyl methacrylate dissolved in In 1010mmol tetrahydrofuran, after passing nitrogen for 20min, add 2.02mmol initiator azobisisobutyronitrile, heat up to 70°C, reflux for 12h, cool to room temperature, then deposit the reaction solution in 5000mL petroleum ether, suction filter, wash, After drying, 80 mmol of modified polyhydroxyethyl methacrylate was obtained, with a yield of 79.2%;

[0026] Preparation and detection of hypochlorite colorimetric - fluorescent fiber membrane:

[0027] b. Put 0.5 g of the modified polyhydroxyethyl methacrylate obtained in step a and 9.5 g of polystyrene in a mortar and grind them to powder, and mix them uniformly to obtain 10 g of the mixed material; ...

Embodiment 2

[0030] Preparation of modified poly(hydroxyethyl methacrylate):

[0031] a, 0.1mmol colorimetric-fluorescent probe molecule containing double bond ((E)-((4-(2-(4-cyano-5-(dicyanomethylene)-2,2-dimethyl Base-2,5-dihydrofuran-3-yl)vinyl)phenyl)azanediyl)bis(ethane-2,1-diyl)diacrylate) dissolved in 100mmol hydroxyethyl methacrylate In 1001mmol tetrahydrofuran, after passing nitrogen for 20min, add 2.002mmol initiator azobisisobutyronitrile, raise the temperature to 70°C, reflux for 12h, cool to room temperature, and deposit the reaction solution in 5000mL petroleum ether, suction filter, wash and dry , to obtain 76 mmol of modified polyhydroxyethyl methacrylate, with a yield of 75.9%;

[0032] Preparation and detection of hypochlorite colorimetric - fluorescent fiber membrane:

[0033] b. Put 2.0 g of the modified polyhydroxyethyl methacrylate obtained in step a and 8.0 g of polystyrene in a mortar and grind them to powder, and mix them uniformly to obtain 10 g of the mixed mat...

Embodiment 3

[0036] Preparation of modified poly(hydroxyethyl methacrylate):

[0037]a. Mix 0.2mmol colorimetric-fluorescent probe molecule with double bond ((E)-((4-(2-(4-cyano-5-(dicyanomethylene)-2,2-dimethyl Base-2,5-dihydrofuran-3-yl)vinyl)phenyl)azanediyl)bis(ethane-2,1-diyl)diacrylate) dissolved in 100mmol hydroxyethyl methacrylate In 1002mmol tetrahydrofuran, after passing nitrogen for 20min, add 2.004mmol initiator azobisisobutyronitrile, heat up to 70°C, reflux for 12h, cool to room temperature, the reaction solution is deposited in 5000mL petroleum ether, suction filtered, washed and dried , to obtain 77 mmol of modified polyhydroxyethyl methacrylate, with a yield of 77.2%;

[0038] Preparation and detection of hypochlorite colorimetric - fluorescent fiber membrane:

[0039] b. Put 1.25 g of the modified polyhydroxyethyl methacrylate obtained in step a and 8.75 g of polystyrene into a mortar and grind them to powder, and mix them uniformly to obtain 10 g of the mixed material;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com