Composite material and preparation method thereof, and quantum dot light-emitting diode

A composite material and molar weight technology, applied in the field of nanomaterials, can solve the problems of limited application of p-type ZnO, improve the overall luminous performance and display performance, the preparation method is simple and easy, and the hole carrier concentration is increased. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

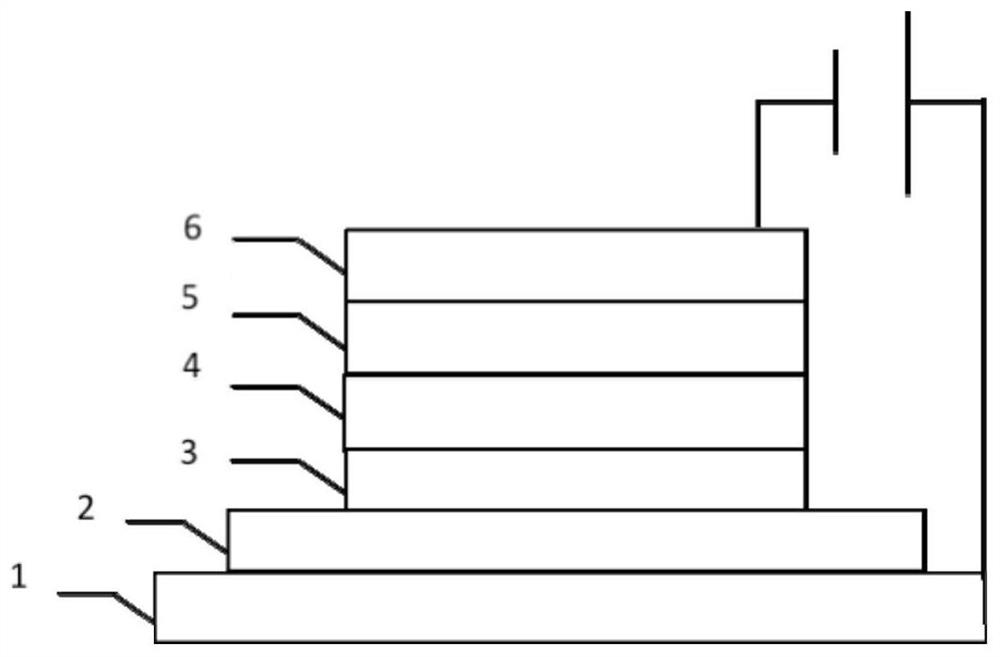

Image

Examples

preparation example Construction

[0021] On the other hand, the embodiment of the present invention also provides a method for preparing a composite material, comprising the following steps:

[0022] S01: Provide zinc salt, lithium salt and nitrogen-containing element precursor salt;

[0023] S02: dissolving the zinc salt, lithium salt and nitrogen-containing element precursor salt in a solvent, and performing heat treatment under alkaline conditions to obtain a precursor solution;

[0024] S03: Annealing the precursor solution to obtain the composite material.

[0025] In the composite preparation method provided in the embodiment of the present invention, the precursor solution is first prepared by using zinc salt, lithium salt and nitrogen-containing element precursor salt, and then the precursor solution is annealed to obtain a Li and N co-doped The composite material of p-type ZnO nanoparticles; the preparation method is a simple sol-gel method, the preparation method is simple and easy, suitable for lar...

Embodiment 1

[0047] Taking zinc chloride, lithium chloride, ammonium chloride, methanol, and sodium hydroxide as examples, the preparation method of Li-N / ZnO composite material will be introduced in detail below.

[0048] First, add appropriate amount of zinc chloride, lithium chloride and ammonium chloride to 50ml of methanol to form a solution with a total concentration of 0.2M-1M, wherein the molar ratio of zinc: lithium + nitrogen is 1:0.1%-10%; lithium : The molar ratio of nitrogen is 1:2-3. Then stir and dissolve at 60°C, add dropwise sodium hydroxide dissolved in 10ml methanol lye (molar ratio OH - :M x+ =1.8:1-2.5:1, M is zinc and lithium). Continue to stir at 60°C for 2h-4h to obtain a homogeneous transparent solution. Subsequently, after the solution is cooled, the treated ITO is spin-coated with a homogenizer and annealed at 300-350°C.

Embodiment 2

[0050] Taking zinc nitrate, lithium nitrate, urea, propanol, and ethanolamine as examples, the preparation method of Li-N / ZnO composite is introduced in detail below.

[0051] First, add appropriate amount of zinc nitrate, lithium nitrate and urea to 50ml of propanol to form a solution with a total concentration of 0.2M-1M, wherein the molar ratio of zinc: lithium + nitrogen is 1:0.1%-10%; lithium: nitrogen The molar ratio is 1:2-3. Then stir and dissolve at 60°C, dropwise add ethanolamine dissolved in 10ml methanol lye (molar ratio, ethanolamine: M x+ =1.8:1-2.5:1, M is zinc and lithium). Continue to stir at 60°C for 2h-4h to obtain a homogeneous transparent solution. Subsequently, after the solution is cooled, the treated ITO is spin-coated with a homogenizer and annealed at 300-350°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com