Composition containing LiPF6 crystals and water

A technology of composition and moisture, which is applied in the direction of lithium hexafluorophosphate, lithium compounds, alkali metal compounds, etc., can solve the problems of high cost and the purity of undisclosed lithium hexafluorophosphate products, and achieve the effects of low cost, high product quality stability and sufficient reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

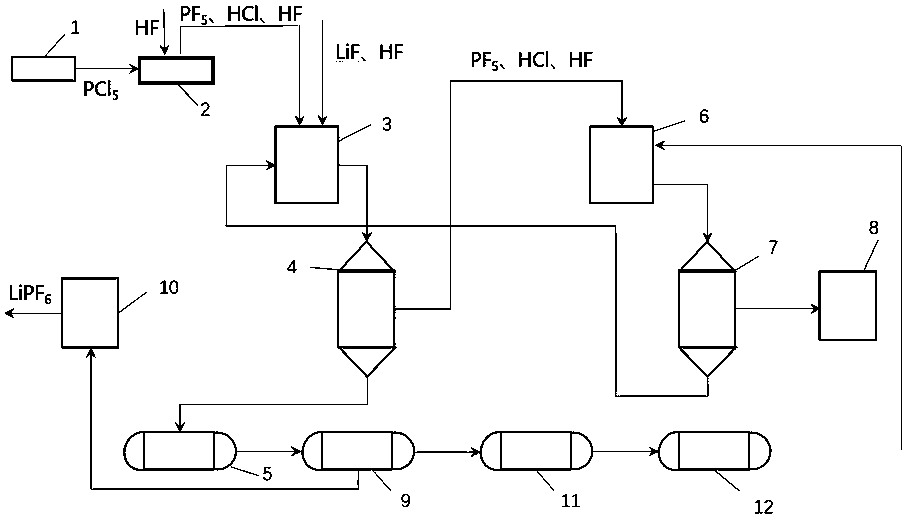

[0058]The water content in the anhydrous hydrogen fluoride was reduced to 8 ppm by the F2 bubbling method. The foaming time is 2 hours, the temperature is -20°C, and the F2 flow rate is 20g / hr. The phosphorus pentachloride is transported to the phosphorus pentafluoride generator 2 with anhydrous hydrogen fluoride with a cooling jacket through the solid conveyor 1 with a metering device, and the temperature is controlled at about 0°C, and the phosphorus pentachloride That is, react with anhydrous hydrogen fluoride to produce phosphorus pentafluoride and hydrogen chloride. The mixed gas of phosphorus pentafluoride, hydrogen chloride and entrained hydrogen fluoride gas is passed into the first microchannel reactor 3 to form the first feed stream. Add anhydrous hydrogen fluoride into the dissolution tank with cooling jacket and agitator, and add lithium fluoride into the dissolution tank with a solid feeding device while cooling, and control the dissolution temperature to about 0...

Embodiment 2

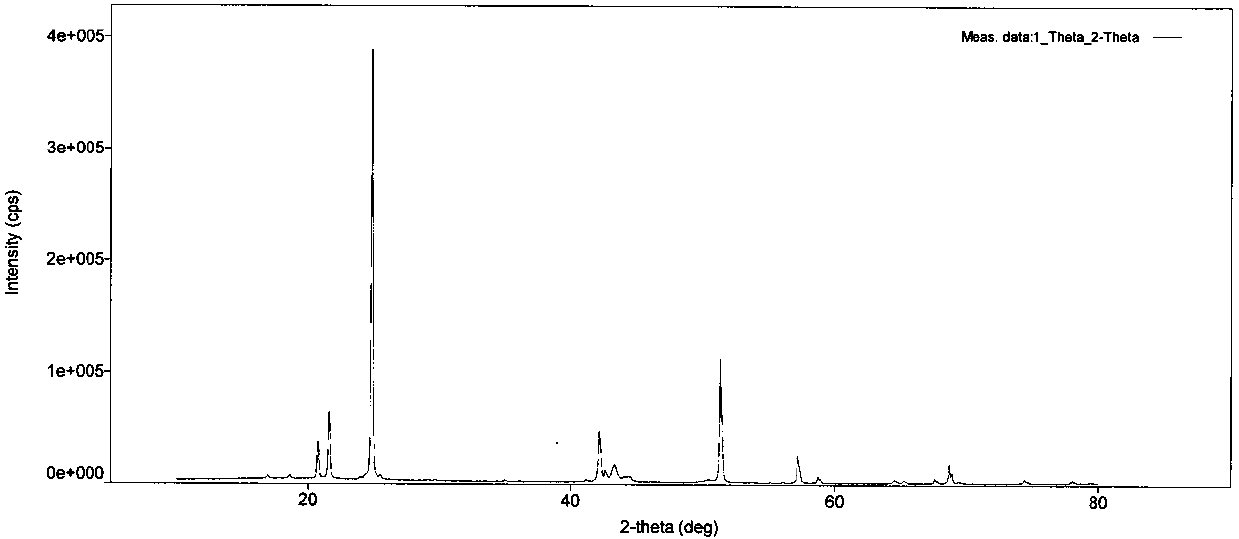

[0061] The difference between the production process of Example 2 and Example 1 is that heat treatment is performed after drying and deacidification in the drying system, and the dried product is supplied to a heating furnace. The inside of the heating furnace was evacuated and filled with phosphorus pentafluoride gas. The heating time was 2 hours, the temperature was 98° C., the pressure was atmospheric pressure, cooled to room temperature, and the inside of the container was evacuated to obtain the composition. After testing, in the generated composition, the lithium hexafluorophosphate crystal content is 99.9952%, the moisture content is 2ppm, 45% of the crystal particle size is greater than or equal to 0.2mm and less than 0.25mm, and 45% of the crystal particle size is greater than or equal to 0.25mm and less than or equal to 0.3 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com