Plasticized polymer ionic liquid film and method for selective separation of chromium (VI) through same

An ionic liquid and polymer technology, applied in chemical instruments and methods, ion-exchanged water/sewage treatment, water pollutants, etc., can solve problems such as system instability, cumbersome technical operations, environmental hazards, etc. Stability, high mass transfer stability, effect of improving crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

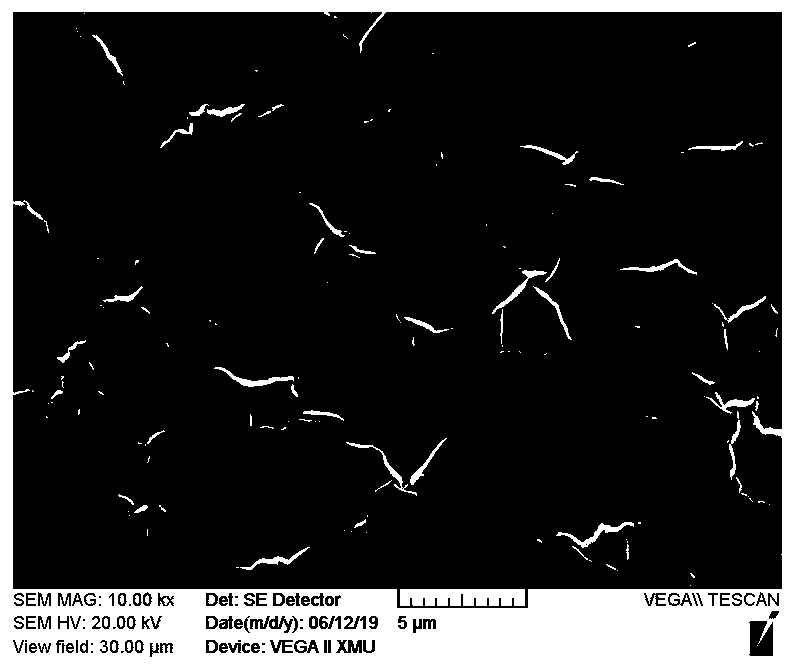

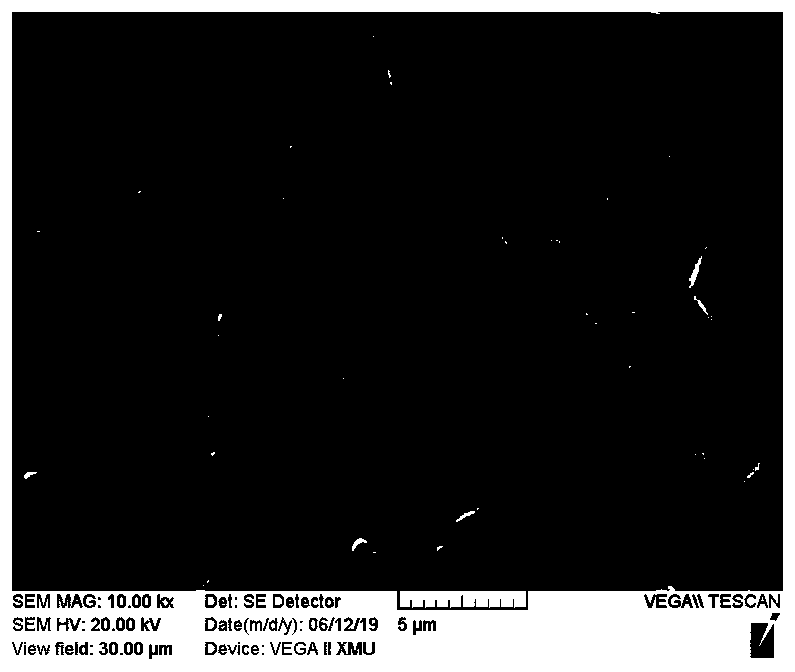

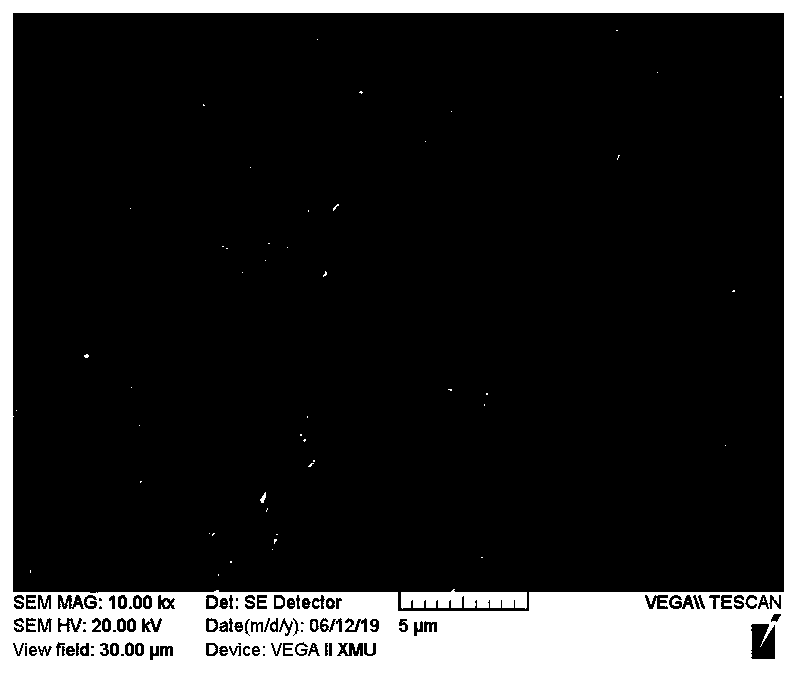

[0035] Embodiment 1: With dioctyl phthalate (DOP) as plasticizer, by mass percentage, with 3.47% polyvinyl chloride, 1.85% aliphatic amine tri-n-octylamine, 92.6% THF are mixed in 25 React at ℃ for 12 hours, add 2.08% dioctyl phthalate, stir magnetically until homogeneous and transparent casting solution, pour the casting solution into a flat-bottomed airtight container with a diameter of 55 mm and place it horizontally, and control the spreading thickness of the solution at 1.0mm, kept open to the atmosphere, volatilized at 35°C for 15h to constant weight to obtain a liquid film. Immerse it in 0.1M hydrochloric acid solution for 12h and take it out. The resulting plasticized plasticized polymer ionic liquid membrane was fixed in the central junction of the osmotic device. The effective membrane area is 3.14cm 2 , with a thickness of 150 μm. A solution containing chromium (VI) and zinc (II) with a volume of 80 mL and a concentration of 12 mg / L was adjusted to pH 1.3 with hy...

Embodiment 2

[0036] Embodiment 2: With o-nitrophenyl octyl ether (NPOE) as the plasticizer, by mass percent, 3.5% polyvinyl chloride, 2.5% aliphatic amine tri-n-octylamine and 40.5% tetrahydrofuran and 51% N,N-dimethylformamide mixed, reacted at 25°C for 24 hours, added 2.5% o-nitrophenyl octyl ether, and magnetically stirred until a homogeneous transparent casting solution. Pour the casting solution into a flat-bottomed airtight container with a diameter of 55mm and place it horizontally, control the thickness of the solution to spread at 2.0mm, keep it open to the atmosphere, volatilize at 35°C for 4 hours, and then volatilize at 105°C under normal pressure to constant weight A liquid film is then obtained. Immerse it in 0.5M hydrochloric acid solution for 24 hours, then take it out and keep it sealed. The resulting plasticized polymeric ionic liquid membrane was immobilized in the central junction of the osmotic device. The effective membrane area is 3.14cm 2 , with a thickness of 25...

Embodiment 3

[0037] Embodiment 3: with tributyl phosphate (TBP) as plasticizer, by mass percent, the 1,4-dioxane of 3.5% polyvinyl chloride 2.5% aliphatic amine tri-n-octylamine and 93% Mix together, react at 50°C for 18 hours, stir magnetically to a homogeneous and transparent casting solution, add 1.0% tributyl phosphate and stir evenly, control the spreading thickness of the solution at 1.8mm, pour the casting solution into a level with a diameter of 55mm Put it in a flat-bottomed airtight container, keep it open to the atmosphere, volatilize at 70°C for 12 hours to a constant weight to obtain a liquid film. Immerse it in 0.1M hydrochloric acid solution for 18 hours, then take it out and keep it sealed. The resulting plasticized polymeric ionic liquid membrane was immobilized in the central junction of the osmotic device. The effective membrane area is 3.14cm 2 , with a thickness of 250 μm. A solution containing chromium (VI) and zinc (II) with a volume of 80 mL and a concentration o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com