Gas mask composite material and production technology thereof

A composite material and gas mask technology, which is applied in the field of gas mask mask composite materials and its production technology, can solve the problems of poor weather resistance of materials, affecting air permeability, obvious problems, etc., to achieve perfect air permeability and improve air permeability , Improve the effect of weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

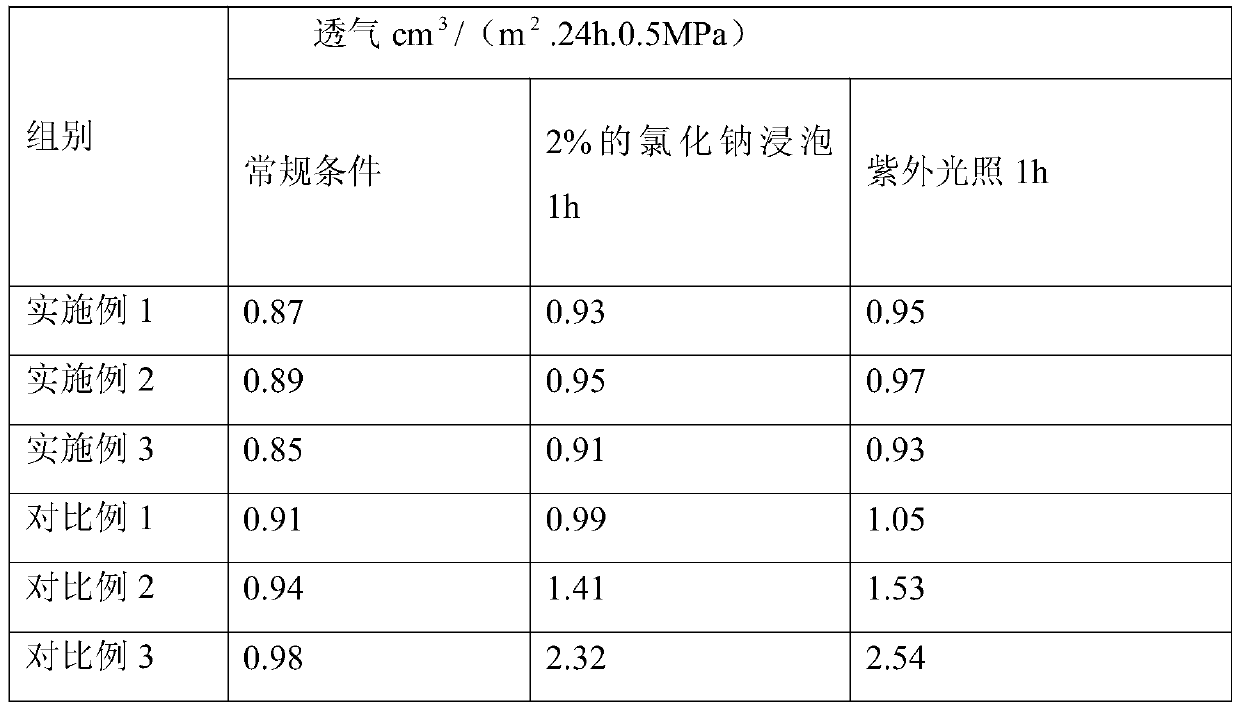

Examples

Embodiment 1

[0029] A kind of gas mask mask composite material of the present embodiment, comprises the raw material of following weight portion:

[0030] 55 parts of modified chlorobutyl rubber, 10 parts of hybrid three-dimensional network graphene, 5 parts of carbon black, 4 parts of dioctyl sebacate, 2 parts of anti-aging agent, 1 part of accelerator EDC, 15 parts of zinc chloride.

[0031] The preparation method of the modified chlorinated butyl rubber of the present embodiment is:

[0032] Step 1: Activation of bentonite: Calcinate bentonite at 600°C for 1 hour, then naturally cool to room temperature, and then send it into a magnetic stirrer with nano-modified liquid at a weight ratio of 1:3, start the magnetic stirrer, and stir the temperature Raise to 75°C, stirring speed is 350r / min, stirring time is 2h, after stirring, centrifuge and dry;

[0033] Step 2, activated bentonite modified chlorinated butyl rubber: the activated bentonite prepared in step 1 was added to the chlorinate...

Embodiment 2

[0046] A kind of gas mask mask composite material of the present embodiment, comprises the raw material of following weight portion:

[0047] 65 parts of modified chlorobutyl rubber, 20 parts of hybrid three-dimensional network graphene, 10 parts of carbon black, 8 parts of dioctyl sebacate, 6 parts of anti-aging agent, 3 parts of accelerator EDC, 25 parts of zinc chloride.

[0048] The preparation method of the modified chlorinated butyl rubber of the present embodiment is:

[0049] Step 1, activate bentonite: first calcinate bentonite at 800°C for 2 hours, then naturally cool to room temperature, and then send it into the magnetic stirrer with the nano-modified liquid at a weight ratio of 1:3, start the magnetic stirrer, and stir the temperature Raise to 85°C, the stirring speed is 450r / min, the stirring time is 5h, after the stirring is completed, centrifuge and dry;

[0050] Step 2, activated bentonite modified chlorinated butyl rubber: the activated bentonite prepared in...

Embodiment 3

[0063] A kind of gas mask mask composite material of the present embodiment, comprises the raw material of following weight portion:

[0064] 60 parts of modified chlorobutyl rubber, 15 parts of hybrid three-dimensional network graphene, 7.5 parts of carbon black, 6 parts of dioctyl sebacate, 4 parts of antioxidant, 2 parts of accelerator EDC, 20 parts of zinc chloride.

[0065] The preparation method of the modified chlorinated butyl rubber of the present embodiment is:

[0066] Step 1, activate bentonite: first calcinate bentonite at 700°C for 1.5h, then naturally cool to room temperature, and then send the bentonite into the magnetic stirrer with the nano-modified liquid at a weight ratio of 1:3, start the magnetic stirrer, and stir The temperature rises to 80°C, the stirring speed is 400r / min, and the stirring time is 3.5h. After the stirring is completed, centrifuge and dry;

[0067] Step 2, activated bentonite modified chlorinated butyl rubber: the activated bentonite p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com