Supergravity rotational flow micro-bubble ozone oxidation advanced treatment system for wastewater

A technology of ozone oxidation and advanced treatment, applied in the direction of oxidation water/sewage treatment, water/sewage treatment, water/sewage treatment equipment, etc., can solve the problems of low reaction efficiency, low mineralization degree of organic pollutants, high energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

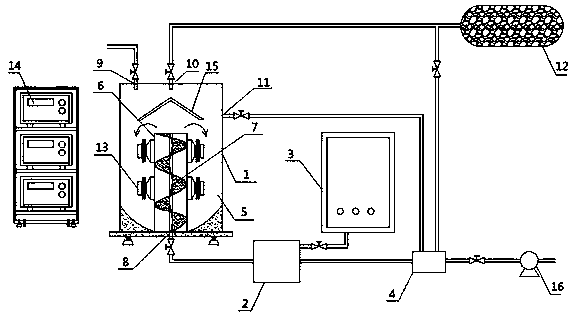

[0024] During specific implementation: if figure 1As shown, a high-gravity cyclone micro-bubble ozonation wastewater advanced treatment system includes a pre-mixing system and a high-gravity oxidation system 1, and the pre-mixing system includes gas for fully mixing wastewater and ozone and forming micro-bubbles The ozone bubble nanometerization device 2 of the liquid mixture, the ozone bubble nanometerization device 2 is respectively connected to the ozone generator 3 and the exhaust gas utilization device 4 through pipelines; the high gravity oxidation system 1 includes a coaxial outer cylinder reaction tank 5 and an inner cylinder reaction tank 6, and the inner cylinder reaction tank 6 is located at the bottom of the outer cylinder reaction tank 5, and a hydrocyclone 7 and an ultrasonic generating device are also arranged in the inner cylinder reaction tank 6, and the ozone bubbles are nanometerized The water outlet of the device 2 is connected to the liquid inlet 8 provide...

Embodiment 2

[0032] With embodiment 1, only the following parameters are different: the ozone generator is an oxygen source ozone generator, the ozone concentration is 4mg / L, the ozone air intake is 80mL / min, the ozone output is 5g / h, the inclination angle of the hydrocyclone 45°, the rotation speed is 10m / s, the ultrasonic frequency is 1000kHz, the ultrasonic power is 0.8KW, the ultrasonic treatment time is 1h, and the gas-liquid mixed liquid inlet flow rate is 1m / s.

Embodiment 3

[0034] With embodiment 1, only the following parameters are different: the ozone generator is an oxygen source ozone generator, the ozone concentration is 2mg / L, the ozone air intake is 20mL / min, the ozone output is 3g / h, the inclination angle of the hydrocyclone The rotation speed is 60°, the rotation speed is 7m / s, the ultrasonic frequency is 8000kHz, the ultrasonic power is 0.5KW, the ultrasonic processing time is 0.5h, and the gas-liquid mixed liquid inlet flow rate is 8m / s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com