Liquid milk product for meal replacement as well as preparation method thereof

A technology for dairy products and liquid milk, which is applied in the direction of milk preparations, dairy products, applications, etc., and can solve the problem of inability to esterify conjugated linoleic acid glycerides, poor product taste, and long heating time of conjugated linoleic acid glycerides To achieve the effect of ensuring stability and reducing body fat rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

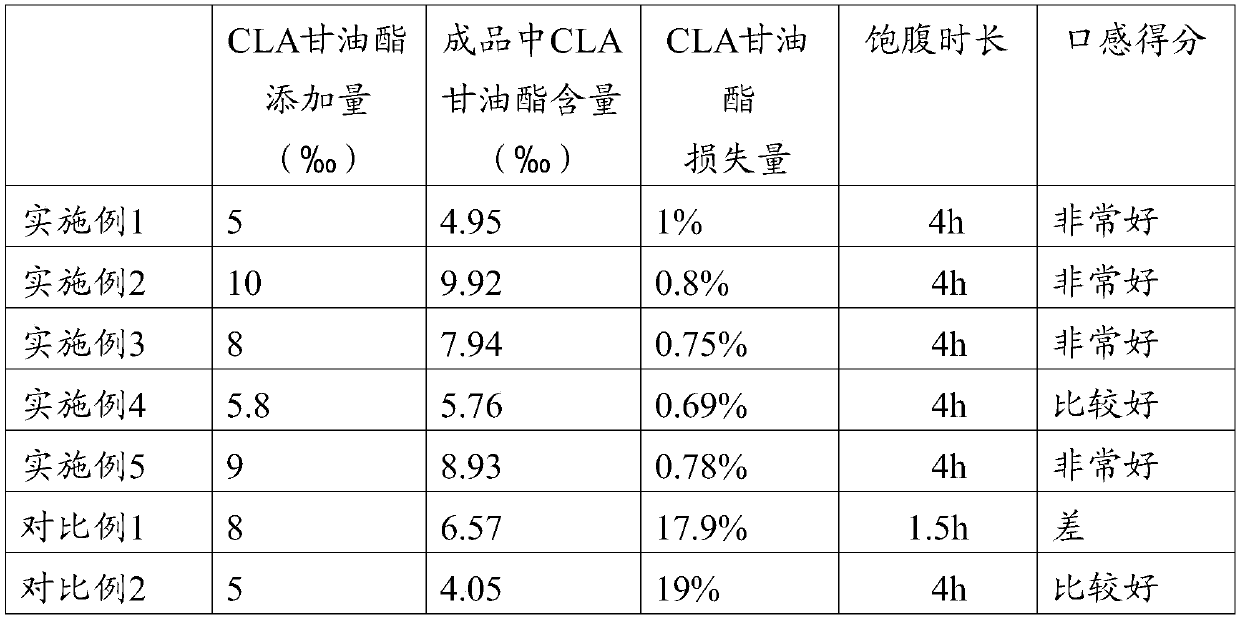

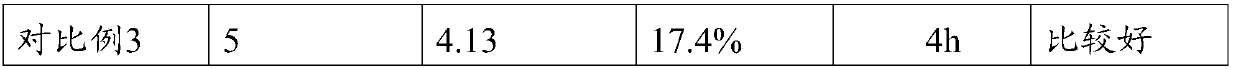

Examples

Embodiment 1

[0071] 1. Raw materials

[0072] Milk: 800 parts

[0073] Conjugated linoleic acid glycerides: 5 parts

[0074] Maltitol: 40 parts

[0075] Resistant dextrin: 15 parts

[0076] Purple potato flour: 2 parts

[0077] Blueberry Juice Concentrate: 2 servings

[0078] Disodium hydrogen phosphate: 0.3 parts

[0079] Vitamin E: 0.016 parts

[0080] Sodium ascorbate: 0.2 parts

[0081] Gellan gum: 0.3 parts

[0082] Hydroxypropyl distarch phosphate: 8 parts

[0083] Compound nutrition fortifier: 0.3 parts

[0084] Oat groats: 15 servings

[0085] Wheat Grains: 15 servings

[0086] Balance: drinking water

[0087] Preparation

[0088] Heat the milk to 40°C-50°C, pre-mix maltitol, stabilizer, emulsifier, resistant dextrin, purple sweet potato powder, and compound nutritional enhancer, then feed and stir for 10-15min

[0089] Heat the product to 75-80°C, stir the vitamin E and sodium ascorbate with 30-50 times the hot milk, then add the feed liquid, stir for 5min-10min, the...

Embodiment 2

[0096] raw material

[0097] Milk: 850 parts

[0098] Conjugated linoleic acid glycerides: 10 parts

[0099] Maltitol: 40 parts

[0100] Resistant dextrin: 10 parts

[0101] Apple fiber: 2 servings

[0102] Jujube Juice Concentrate: 2 parts

[0103] Sodium tripolyphosphate: 0.3 parts

[0104] Vitamin E: 0.02 parts

[0105] Sodium erythorbate: 0.15 parts

[0106] Carrageenan: 0.3 parts

[0107] Hydroxypropyl distarch phosphate: 8 parts

[0108] Compound nutrition enhancer: 0.3 parts

[0109] Blood glutinous rice grains: 15 servings

[0110] Black wolfberry grains: 15 servings

[0111] Balance: drinking water

[0112] Preparation

[0113] a. Heat the milk to 40°C-50°C, pre-mix maltitol, stabilizer, emulsifier, resistant dextrin, apple fiber, and compound nutrition enhancer, then feed and stir for 10-15min

[0114] b. Heat the product to 75-80°C, stir vitamin E and sodium erythorbate with 30-50 times the hot milk, then add the feed liquid, stir for 5min-10min, then ...

Embodiment 3

[0121] raw material

[0122] Milk: 500 parts

[0123] Maltitol: 70 parts

[0124] Resistant dextrin: 20 parts

[0125] Glycerides of Conjugated Linoleate: 8 parts

[0126] Vitamin E: 0.02 parts

[0127] Sodium erythorbate: 0.3 parts

[0128] Locust bean gum: 0.3 parts

[0129] Xanthan gum: 0.02 parts

[0130] Microcrystalline cellulose: 2 parts

[0131] Oxidized hydroxypropyl starch: 10 parts

[0132] Sucrose fatty acid ester: 0.9 parts

[0133] Coix seed granules: 5 servings

[0134] Red bean powder: 2 parts

[0135] Fragrant pear juice: 2 parts

[0136] Compound nutritional fortifier: 0.2 parts

[0137] Disodium hydrogen phosphate: 0.3 parts

[0138] Preparation

[0139] Heat the milk to 40°C-50°C, add maltitol, resistant dextrin, xanthan gum, microcrystalline cellulose, oxidized hydroxypropyl starch, locust bean gum, red bean powder, sucrose fatty acid ester, compound nutrition fortification After the agent is premixed, feed and stir for 10-15min

[0140] He...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com