Primary layer coating used for investment casting shell

A technology of investment casting and surface coating, which is applied in casting molding equipment, molds, and mold components, etc., can solve problems such as adverse effects on the surface finish of castings, uneven distribution of surface coatings, and general surface shell strength. , to achieve the effect of improving strength and surface quality, high practical value, and improving surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

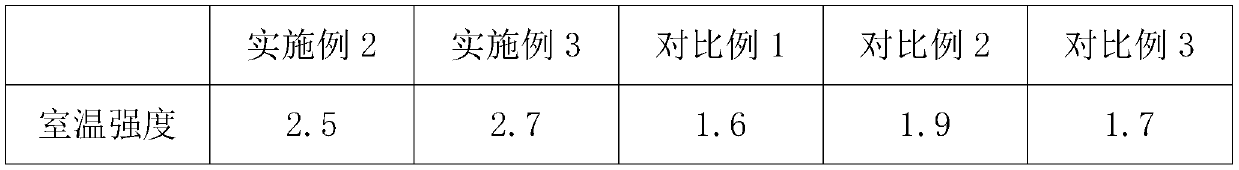

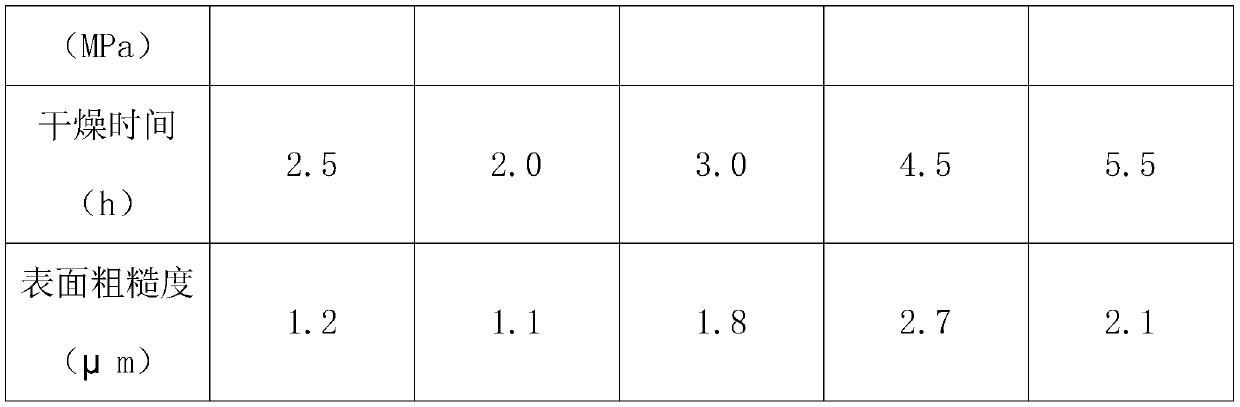

Examples

Embodiment 1

[0022] A kind of surface coating for investment casting mold shell, comprises following raw material:

[0023] Silica Sol, Polyvinyl Acetate-Nano SiO 2 Composite emulsion, quartz powder, polyvinyl alcohol, polyvinylpyrrolidone, sodium polyacrylate, silane coupling agent KH-570, wetting agent, defoamer, water;

[0024] Polyvinyl acetate-nano SiO 2 The weight ratio of composite emulsion to silica sol is 15:100; the weight ratio of quartz powder to silica sol is 350:100; the weight ratio of polyvinyl alcohol, polyvinylpyrrolidone, sodium polyacrylate to silica sol is 0.4:0.2:0.2: 100; the weight ratio of silane coupling agent to silica sol is 0.5:100; the weight ratio of wetting agent to silica sol is 0.3:100; the weight ratio of defoamer to the silica sol is 0.2:100; water to silicon The weight ratio of the sol is 10:100.

Embodiment 2

[0026] A kind of surface coating for investment casting mold shell, comprises following raw material:

[0027] Silica Sol, Polyvinyl Acetate-Nano SiO 2 Composite emulsion, quartz powder, polyvinyl alcohol, polyvinylpyrrolidone, sodium polyacrylate, silane coupling agent KH-570, wetting agent, defoamer, water;

[0028] Polyvinyl acetate-nano SiO 2 The weight ratio of composite emulsion to silica sol is 15:100; the weight ratio of quartz powder to silica sol is 350:100; the weight ratio of polyvinyl alcohol, polyvinylpyrrolidone, sodium polyacrylate to silica sol is 0.4:0.2:0.2: 100; the weight ratio of silane coupling agent to silica sol is 0.5:100; the weight ratio of wetting agent to silica sol is 0.3:100; the weight ratio of defoamer to the silica sol is 0.2:100; water to silicon The weight ratio of the sol is 10:100.

[0029] The solid content of the silica sol is 30%, the pH is 9, and the colloidal particle size is 10nm; the quartz powder is 250 mesh; the polyvinyl alco...

Embodiment 3

[0037] A kind of surface coating for investment casting mold shell, comprises following raw material:

[0038] Silica Sol, Polyvinyl Acetate-Nano SiO 2 Composite emulsion, quartz powder, polyvinyl alcohol, polyvinylpyrrolidone, sodium polyacrylate, silane coupling agent KH-570, wetting agent, defoamer, water;

[0039] Polyvinyl acetate-nano SiO 2 The weight ratio of composite emulsion to silica sol is 20:100; the weight ratio of quartz powder to silica sol is 300:100; the weight ratio of polyvinyl alcohol, polyvinylpyrrolidone, sodium polyacrylate to silica sol is 0.6:0.3:0.3: 100; the weight ratio of silane coupling agent to silica sol is 0.8:100; the weight ratio of wetting agent to silica sol is 0.4:100; the weight ratio of defoamer to silica sol is 0.3:100; the weight ratio of water to silica sol The weight ratio is 12:100.

[0040] The solid content of the silica sol is 35%, the pH is 9.5, and the colloidal particle diameter is 10nm; the quartz powder is 300 mesh; the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com