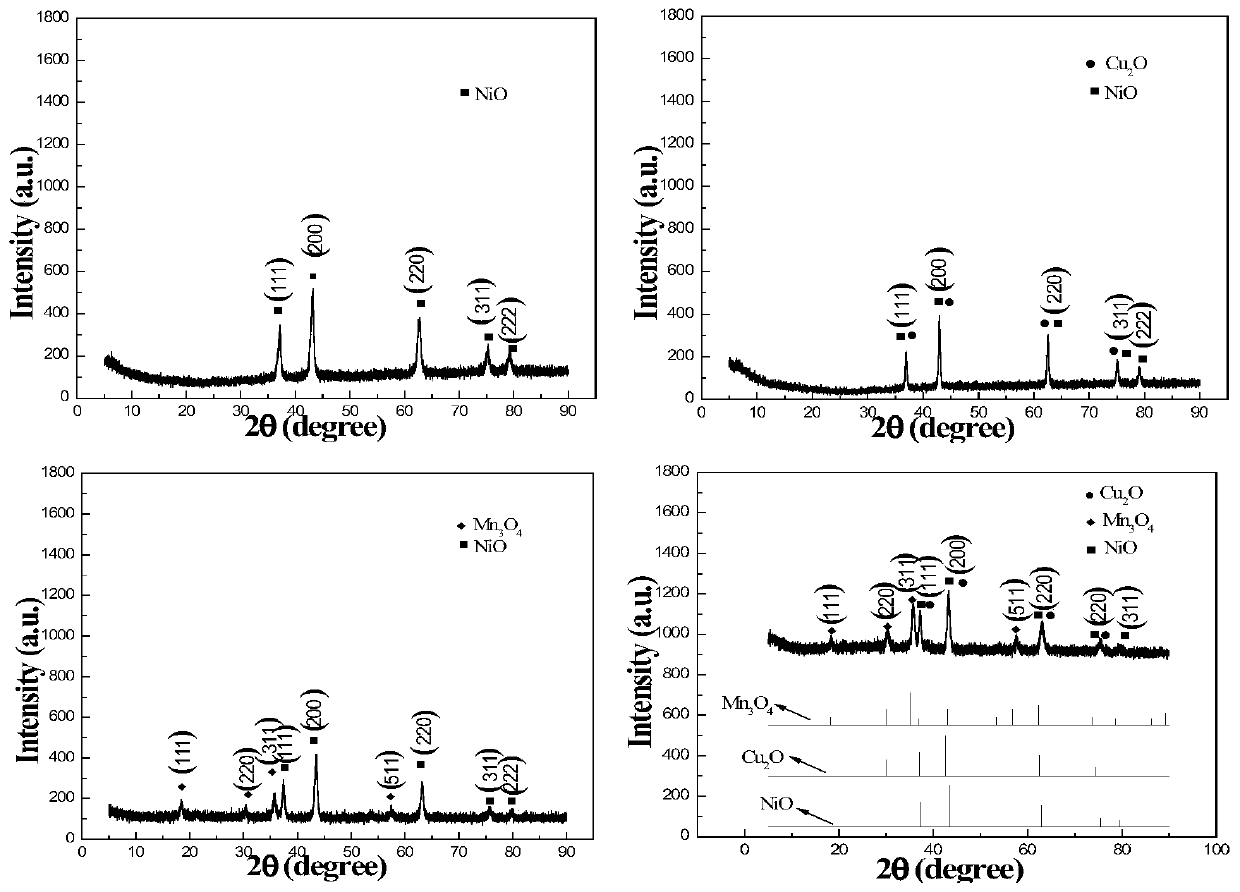

Chain bead-shaped Cu2O-Mn3O4/NiO composite material and preparation method thereof

A cu2o-mn3o4, composite material technology, applied in the manufacture of hybrid/electric double-layer capacitors, hybrid capacitor electrodes, etc., to achieve the effect of improving stability, large capacitance, and simplifying the synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] a Cu 2 O-Mn 3 o 4 The preparation method of / NiO composite material, comprises the following steps:

[0028] (1) Weigh 2.007g of polyvinylpyrrolidone and dissolve it in a solvent of 12.003g of N,N-dimethylformamide, and stir to obtain solution A;

[0029] (2) Weigh 1.013g nickel nitrate hexahydrate and pour it into solution A, stir at room temperature for 1h to obtain mixed solution B;

[0030] (3) Weigh 0.502g manganese acetate and pour it into solution B, and stir at room temperature for 0.5h to obtain mixed solution C;

[0031] (4) Weigh 0.504g of copper acetate and pour it into solution C, and stir at room temperature for 0.5h to obtain mixed solution D;

[0032] (5) Place the mixed solution D in the syringe, and perform electrospinning at a voltage of 17kV, a flow rate of 0.2mL / h and a height of 15cm to prepare Cu-Mn / PVP nanofibers;

[0033] (6) Place the nanofibers obtained in step (5) in a porcelain boat, gradually heat from room temperature to 500°C under ai...

Embodiment 2

[0064] a Cu 2 O-Mn 3 o 4 The preparation method of / NiO composite material, comprises the following steps:

[0065] (1) Weigh 2.002g of polyvinylpyrrolidone and dissolve it in a solvent of 12.003g of N,N-dimethylformamide, and stir to obtain solution A;

[0066] (2) Weigh 2.003g nickel nitrate hexahydrate and pour it into solution A, stir at room temperature for 1h to obtain mixed solution B;

[0067] (3) Weigh 1.002g manganese acetate and pour it into solution B, and stir at room temperature for 0.5h to obtain mixed solution C;

[0068] (4) Weigh 1.005g of copper acetate and pour it into solution C, and stir at room temperature for 0.5h to obtain mixed solution D;

[0069] (5) Place the mixed solution D in the syringe, and perform electrospinning at a voltage of 15kV, a flow rate of 0.3mL / h and a height of 15cm to prepare Cu-Mn / PVP nanofibers;

[0070] (6) Place the nanofibers obtained in step (5) in a porcelain boat, gradually heat from room temperature to 500°C under ai...

Embodiment 3

[0072] a Cu 2 O-Mn 3 o 4 The preparation method of / NiO composite material, comprises the following steps:

[0073] (1) Weigh 2.002g of polyvinylpyrrolidone and dissolve it in a solvent of 12.003g of N,N-dimethylformamide, and stir to obtain solution A;

[0074] (2) Weigh 1.503g of nickel nitrate hexahydrate and pour it into solution A, stir at room temperature for 1h to obtain mixed solution B;

[0075] (3) Weigh 0.752g manganese acetate and pour it into solution B, and stir at room temperature for 0.5h to obtain mixed solution C;

[0076] (4) Weigh 0.751g of copper acetate and pour it into solution C, and stir at room temperature for 0.5h to obtain mixed solution D;

[0077] (5) Place the mixed solution D in the syringe, and perform electrospinning at a voltage of 17kV, a flow rate of 0.2mL / h and a height of 18cm to prepare Cu-Mn / PVP nanofibers;

[0078] (6) Place the nanofibers obtained in step (5) in a porcelain boat, gradually heat from room temperature to 500°C under...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com