Method for preparing layered beta-nickel hydroxide/graphene material by utilizing induction effect of surface charges

A nickel hydroxide and surface charge technology, applied in the direction of hybrid capacitor electrodes, etc., can solve the problems of difficult control of the reaction process, uneven material composition, etc., to achieve uniform and stable crystal phase composition, accelerated aggregation and growth, excellent dispersion and penetration performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1 prepares nickel hydroxide precursor

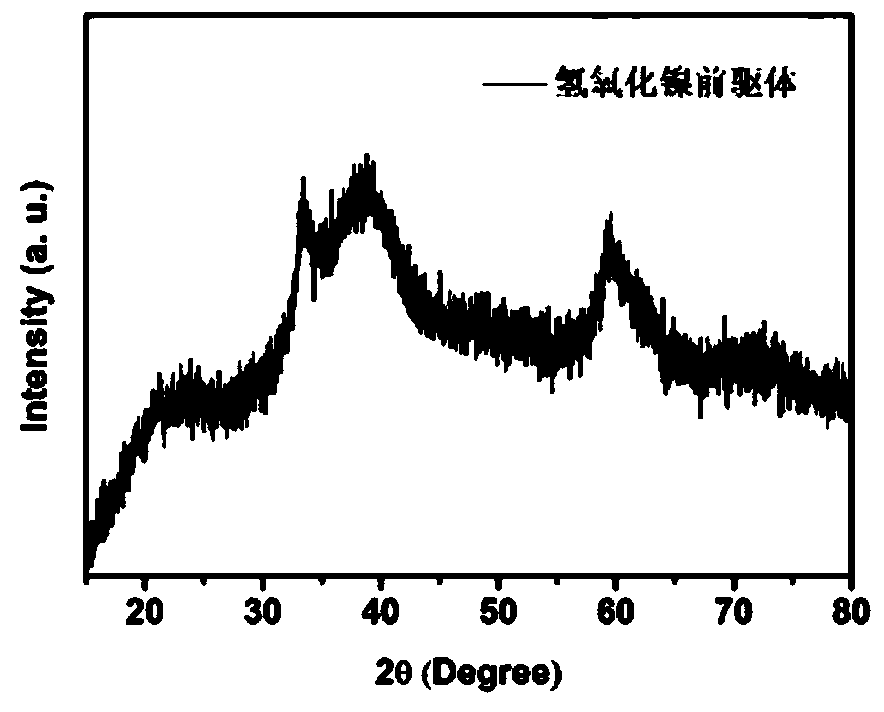

[0034] 2.5759g NiSO 4 ·7H 2 O and 0.132g NaOH were added to 100mL double-distilled water respectively, stirred for 0.5h to mix evenly, and a green precipitate was obtained after standing, after centrifugation and repeated washing, the precursor Ni(OH) 2 0.75H 2 O, its X-ray diffraction pattern is as follows figure 1 Shown; After the zeta potential test, the prepared precursor Ni(OH) 2 0.75H 2 The O potential is +12mV.

Embodiment 2

[0035] The improved Hummers method of embodiment 2 prepares graphene oxide

[0036] Add 3g flake graphite into 400mL mixed acid and stir evenly, this mixed acid is made of 85% concentrated H 2 SO 4 and 75%H 3 PO 4 According to the composition of 9:1 volume ratio, slowly add 18g KMnO under ice bath condition 4 Finally, stir for 0.5h to mix evenly. When the solution is dark green, react in a water bath at 50°C for 24h until the solution turns dark brown. Add 400mL of deionized water and raise the temperature to 98°C for pyrolysis, then add 3mL of H 2 o 2 Make the solution change from dark brown to bright yellow, after standing to remove the supernatant, add 200mL 5% HCl solution to wash, after repeated centrifugation, water washing, and vacuum drying, graphene oxide is obtained; after the zeta potential test, the prepared graphite oxide The ene potential is -43mV.

Embodiment 3

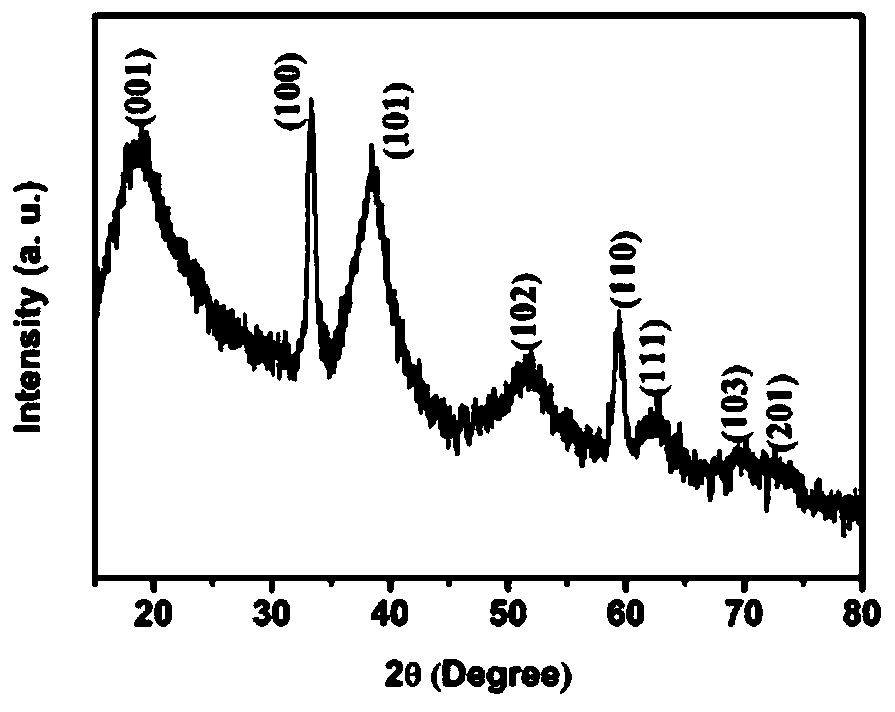

[0037] Embodiment 3 prepares layered β-nickel hydroxide (nickelite type nickel hydroxide) / graphene material

[0038] (1) Surface-modified nickel hydroxide precursor: Dissolve 1.0g of N,N,N-trimethyl-1-tetradecylammonium bromide in 100mL of distilled water, add 0.75g of Example 1 to prepare Ni(OH ) 2 0.75H 2 O, ultrasonically dispersed for 1h to obtain modified Ni(OH) 2 0.75H 2 O dispersion;

[0039] (2) Electrostatic composite: to modified Ni(OH) 2 0.75H 2 Add 1.0 g graphene oxide to the O dispersion, stir thoroughly at 25°C and disperse ultrasonically for 1 h, so that the precursor nanoparticles are uniformly adsorbed and dispersed on the surface of graphene oxide, and after centrifugation, the intermediate product Ni(OH) 2 0.75H 2 O / graphene oxide composites;

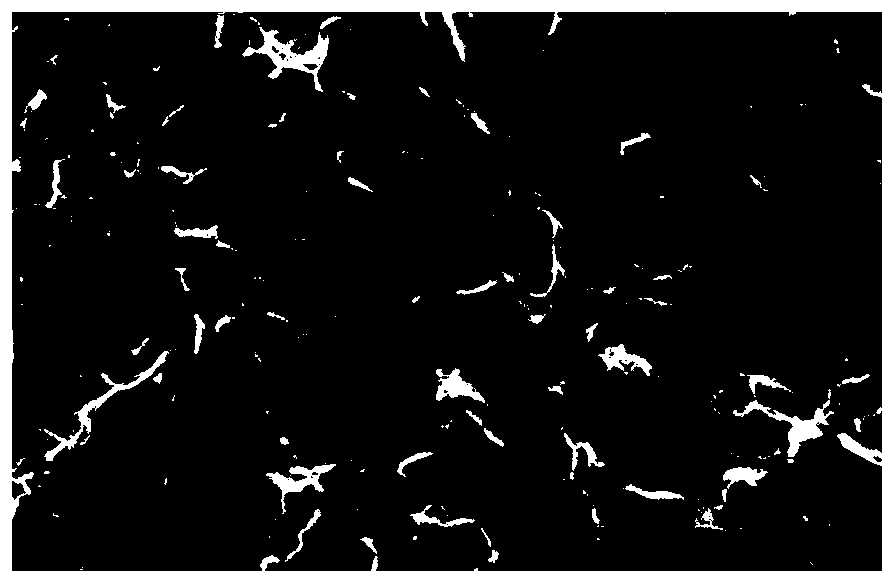

[0040] (3) Reduction: Disperse the obtained intermediate product in 150 mL of DMF, and reflux in an oil bath at 95°C for 16 hours. During the reflux process, add 200 μL of hydrazine hydrate to reduce graphite ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com