Fly ash ceramsite and preparation method thereof

A technology of fly ash ceramsite and cavity, which is applied in the field of solid waste resource utilization, can solve the problems of high bulk density, high water absorption rate, low water absorption rate, etc. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] (1) adding the coal slime containing humic acid into a granulator to granulate, and obtaining a ball with a diameter of 3 mm to form a nucleating agent;

[0046] (2) Mix 75 parts of fly ash, 14.7 parts of albite, 5 parts of clay, and 0.3 parts of silicon carbide, and use the mixture to coat a nucleating agent (7 parts by mass) obtained in step (1) , and then added to a granulator for granulation to obtain pellets with a diameter less than 20mm;

[0047] (3) Dry the pellets obtained in step (2) at 80°C, then place them in a sintering furnace and heat up to 1180°C for 10 minutes. After the sintering is completed, cool down to below 500°C with the furnace, take it out, and cool it down to room temperature naturally. Get fly ash ceramsite.

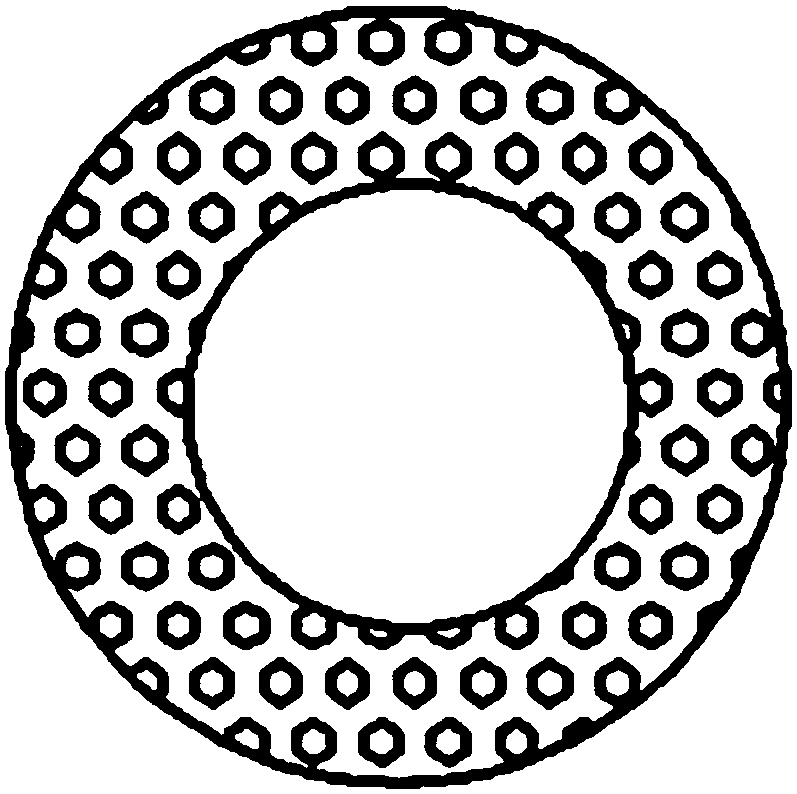

[0048] Such as figure 1 As shown, the fly ash ceramsite prepared in this embodiment has a cavity, and the area outside the cavity is distributed with uniform pores.

Embodiment 2

[0050] (1) The coal slime containing humic acid is added into a granulator and granulated to obtain a ball with a diameter of 4.2mm to form a nucleating agent;

[0051] (2) Mix 82 parts of fly ash, 8 parts of albite, 4.5 parts of clay, and 0.5 parts of silicon carbide, and use the mixture to coat a nucleating agent (9 parts by mass) obtained in step (1) , and then added to a granulator for granulation to obtain pellets with a diameter less than 20mm;

[0052] (3) Dry the pellets obtained in step (2) at 100°C, then place them in a sintering furnace and heat up to 1210°C for 20 minutes. After the calcination is completed, cool down to below 500°C with the furnace, take it out, and cool it down to room temperature naturally. Obtain the fly ash ceramsite.

Embodiment 3

[0054] (1) Sodium silicate slag is added into a granulator and granulated to obtain a ball with a diameter of 1.3 mm to form a nucleating agent;

[0055] (2) Mix 85 parts of fly ash, 9.2 parts of albite, and 0.8 parts of silicon carbide, and use the mixture to coat a nucleating agent (5 parts by mass) obtained in step (1), and then add the Granulate in a granulator to obtain pellets with a diameter less than 20mm;

[0056] (3) Dry the pellets obtained in step (2) at 120°C, then place them in a sintering furnace and heat up to 1230°C for 20 minutes. After the sintering is completed, cool down to below 500°C with the furnace, take it out, and cool it down to room temperature naturally. Obtain the fly ash ceramsite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com