High-activity silver powder and preparation method and application thereof

A high-activity, silver powder technology, applied in chemical instruments and methods, transportation and packaging, metal processing equipment, etc., can solve the problems of silver powder collapse, difficult precipitation and separation, organic residues, etc., to improve catalytic activity and efficiency, and improve catalytic efficiency , the effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

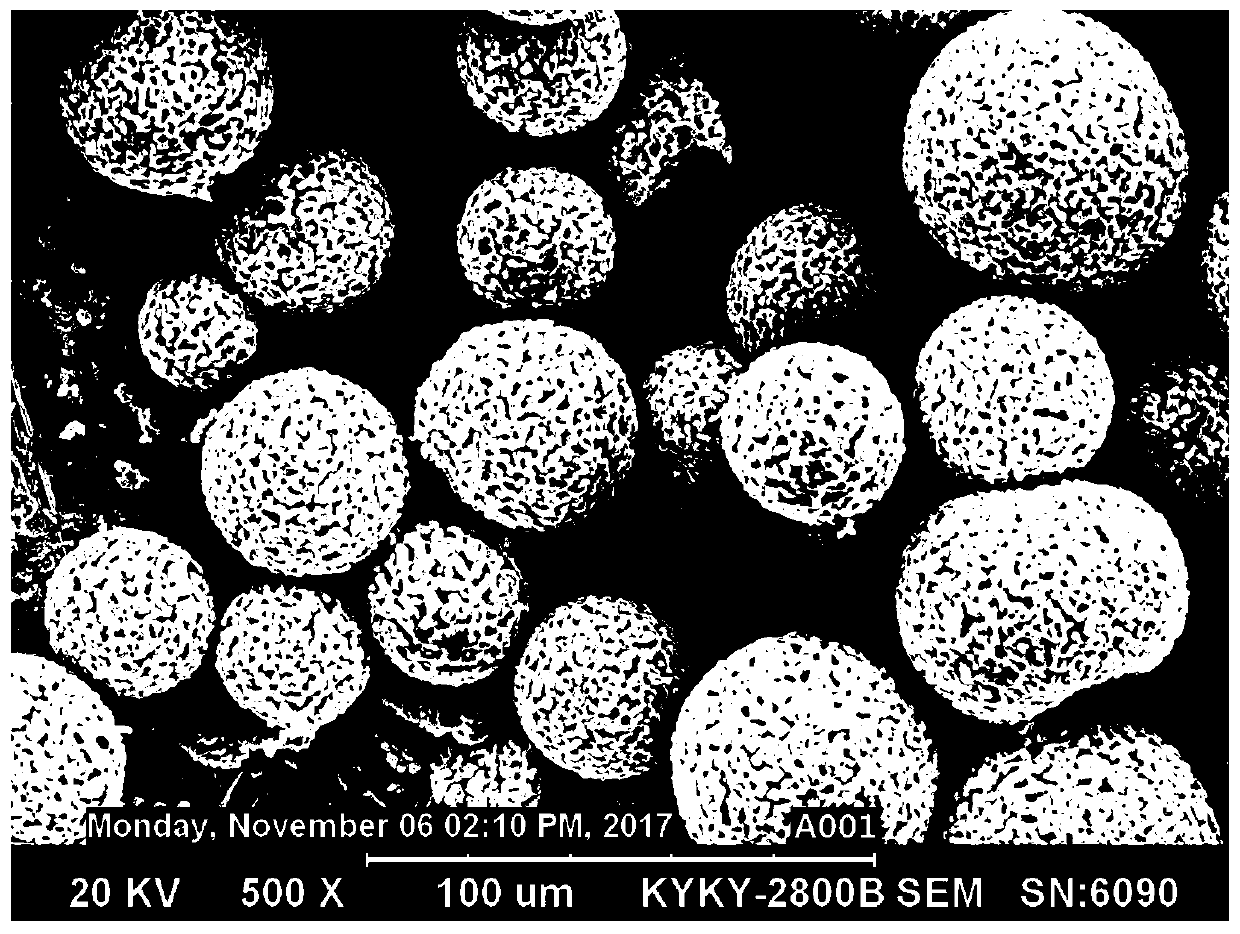

Embodiment 1

[0040] A high activity silver powder, prepared by the following method:

[0041] (1) Weigh 10g of silver nitrate into the reaction kettle and add water to dissolve, add the polyamide-amine polymer solution containing 6.5g dissolved in advance, and then prepare a 50L low-concentration silver nitrate solution system, start stirring to 110r / min Stir evenly at high speed, and maintain the system temperature at 35°C.

[0042](2) Weigh 0.57kg of ascorbic acid into the batching tank and add water to dissolve, add 120g of sodium hydroxide and add water to dissolve to prepare a 2.5L reduction solution system, maintain the system temperature at 45°C, and quickly add the solution to the reaction kettle at one time, The stirring speed was adjusted to 25r / min, and the stirring was maintained at a low speed for 30 minutes, so that the silver grains in the reaction kettle could be attached to the polyamide-amine polymer to form silver grains.

[0043] (3) After the reaction is completed, ad...

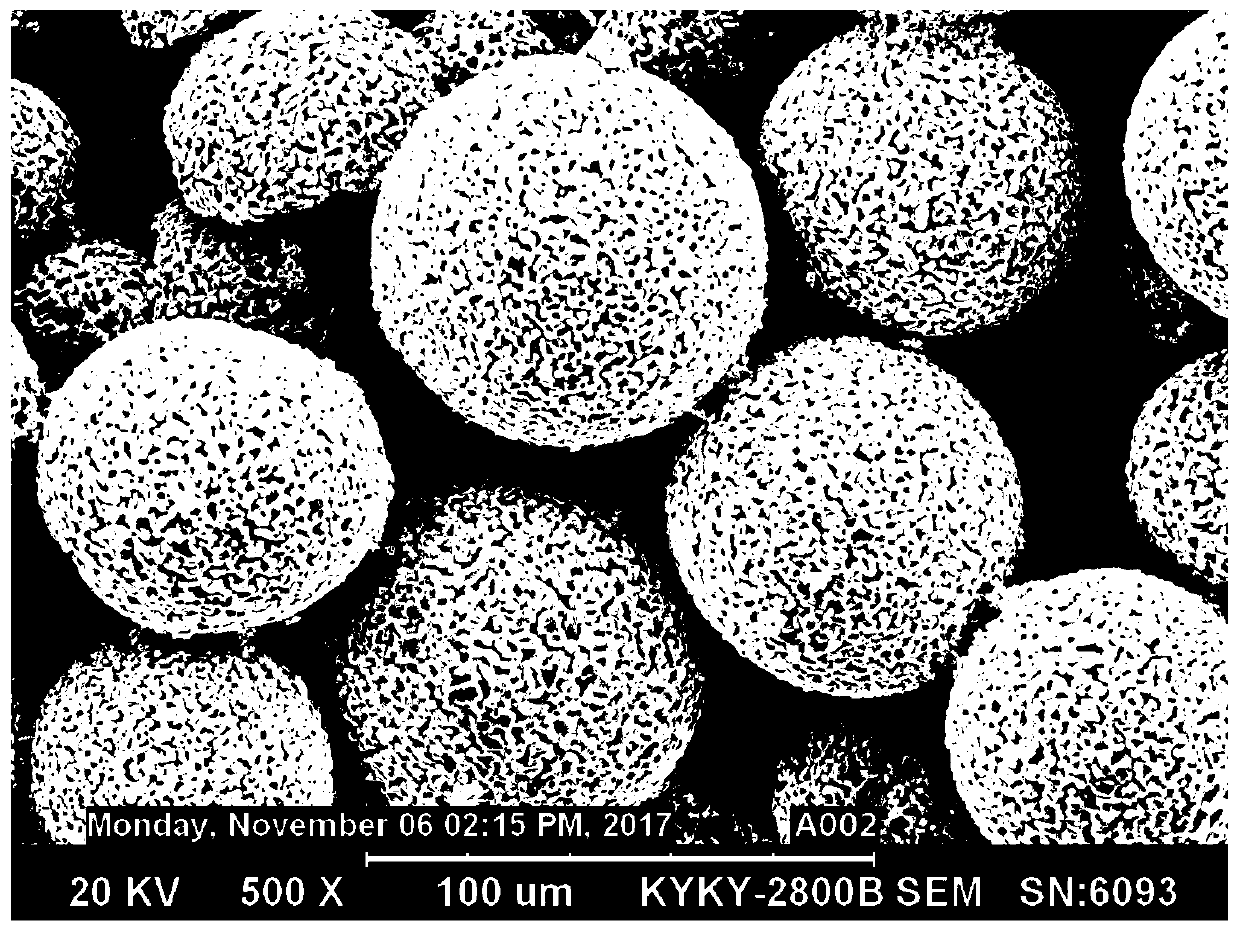

Embodiment 2

[0047] A high activity silver powder, prepared by the following method:

[0048] (1) Weigh 10g of silver nitrate into the reaction kettle and add water to dissolve it, add the polyamide-amine polymer solution containing 2.5g dissolved in advance, then prepare a 70L low-concentration silver nitrate solution system, start stirring to 150r / min Stir evenly at high speed and maintain the system temperature at 45°C.

[0049] (2) Weigh 0.57kg of ascorbic acid to the batching tank and add water to dissolve, add 160g of sodium hydroxide and add water to dissolve to prepare a 2.5L reducing solution system, maintain the system temperature at 45°C, and quickly add the solution to the reaction kettle at one time, The stirring speed was adjusted to 15 r / min, and the stirring was maintained at a low speed for 60 minutes, so that the silver grains in the reaction kettle could be attached to the polyamide-amine polymer to form silver grains.

[0050] (3) After the reaction is completed, add 2...

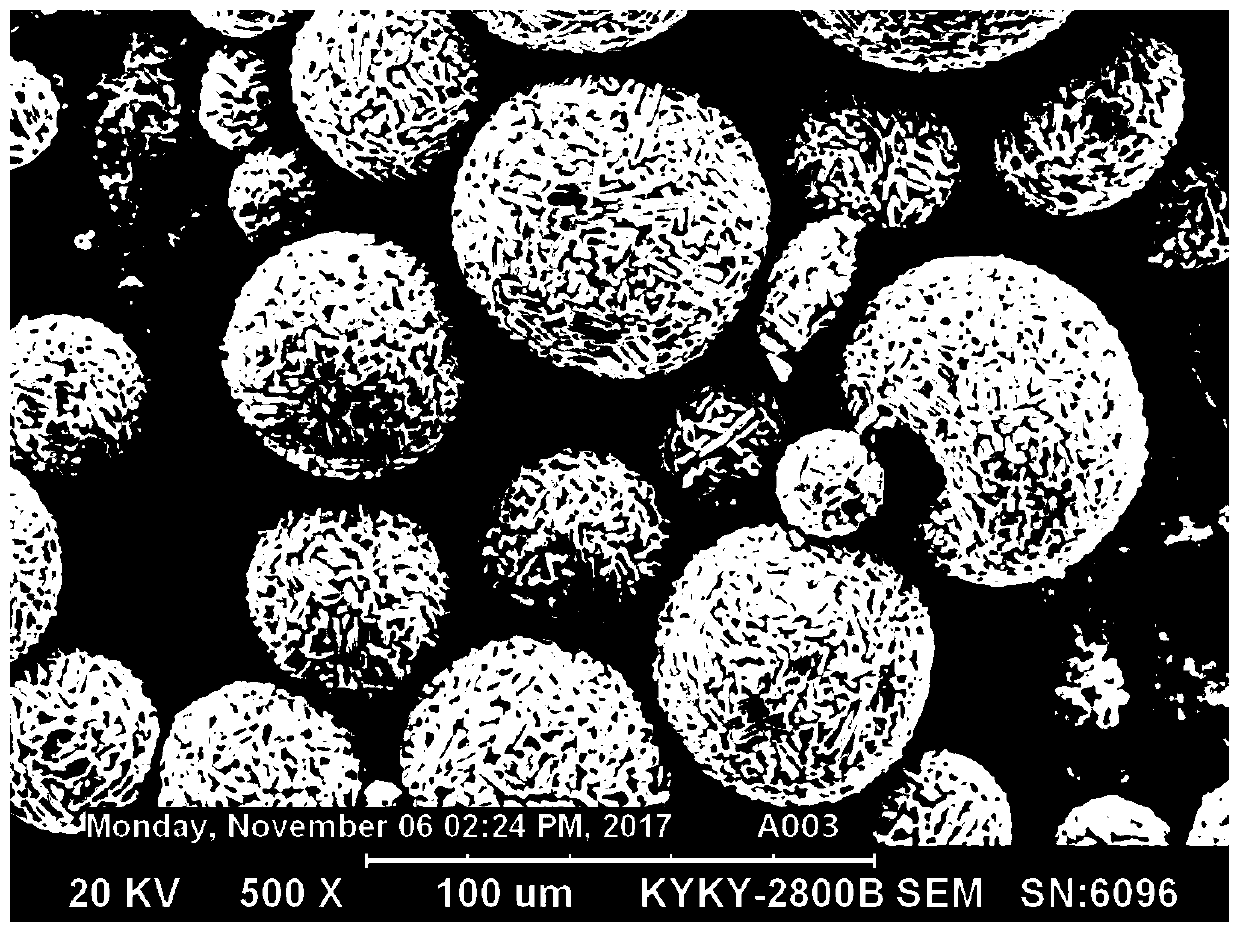

Embodiment 3

[0054] A high activity silver powder, prepared by the following method:

[0055] (1) Weigh 20g of silver nitrate into the reaction kettle and add water to dissolve, add the polyamide-amine polymer solution containing 2.5g dissolved in advance, and then prepare a 70L low-concentration silver nitrate solution system, start stirring to 180r / min Stir evenly at high speed and maintain the system temperature at 55°C.

[0056] (2) Weigh 0.57kg of ascorbic acid to the batching tank and add water to dissolve, add 60g of sodium carbonate and add water to dissolve to prepare a 2.5L reduction solution system, maintain the system temperature at 45°C, and quickly add the solution to the reaction kettle at one time, and stir Adjust the speed to 40r / min, and keep stirring at a low speed for 60 minutes, so that the silver grains in the reaction kettle can be attached to the organic polymer to form silver grains.

[0057] (3) After the reaction is completed, add 25 g of sodium alkylbenzene sul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com