Heparinoid substance sulfonated citric acid modified chitosan and preparation method thereof

A technology of sulfonated citric acid and alkalized chitosan, which is applied in the field of biomedical materials, can solve the problems of harsh reaction conditions, long reaction time, and insignificant improvement of anticoagulation, and achieves simple preparation process, mild and acceptable reaction conditions. control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

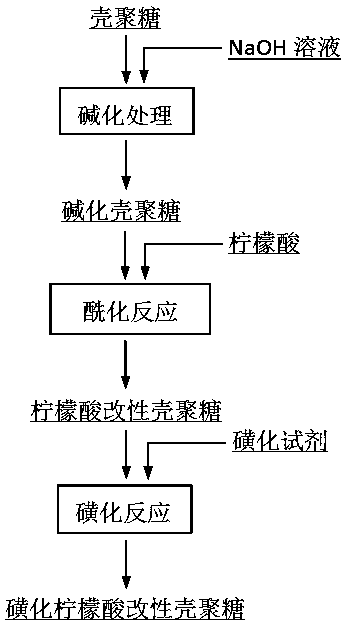

[0031] The preparation process of the present invention is as figure 1 shown. At room temperature, add chitosan (CS) and NaOH solution with a mass fraction of 30% into the container respectively, stir evenly, and freeze in the refrigerator for 10 days. After thawing, remove the lye by filtration to obtain alkalized chitosan sugar; wherein the mass ratio of chitosan to NaOH solution is 1: 5.

[0032] At room temperature, dissolve citric acid (CA) in absolute ethanol, then add alkalized chitosan, stir evenly, and then react at 55°C for 3 hours, wherein the alkalized chitosan, citric acid and absolute ethanol The mass ratio is 1:2:12; after the reaction, add deionized water and stir evenly, wherein the mass ratio of deionized water to absolute ethanol is 2:1; after standing for stratification, take the supernatant at 50 Vacuum evaporation at ℃ to remove ethanol, and then adjust the pH to neutral with dilute hydrochloric acid after cooling; then add acetone to the neutral soluti...

Embodiment 2

[0035]At room temperature, add chitosan (CS) and NaOH solution with a mass fraction of 30% into the container respectively, stir evenly, place in the refrigerator to freeze for 6 days, and after thawing, remove the lye by filtration to obtain alkalized chitosan Sugar; the mass ratio of chitosan to NaOH solution is 1:6.

[0036] At room temperature, dissolve citric acid (CA) in absolute ethanol, then add alkalized chitosan, stir evenly, and then react at 55°C for 3 hours, wherein the alkalized chitosan, citric acid and absolute ethanol The mass ratio is 1:2:15; after the reaction, add deionized water and stir evenly, wherein the mass ratio of deionized water to absolute ethanol is 2:1; after standing for stratification, take the supernatant at 40 Evaporate under vacuum at ℃ to remove ethanol, then adjust the pH to neutral with dilute hydrochloric acid after cooling; then add acetone to the neutral solution, wherein the mass ratio of acetone to deionized water is 0.5:1, resultin...

Embodiment 3

[0039] At room temperature, add chitosan (CS) and NaOH solution with a mass fraction of 35% into the container respectively, stir evenly, place in the refrigerator to freeze for 5 days, and after thawing, remove the lye by filtration to obtain alkalized chitosan Sugar; the mass ratio of chitosan to NaOH solution is 1:3.

[0040] At room temperature, dissolve citric acid (CA) in absolute ethanol, then add alkalized chitosan, stir evenly, and then react at 60°C for 3 hours, wherein the alkalized chitosan, citric acid and absolute ethanol The mass ratio is 1:2:16; after the reaction, add deionized water and stir evenly, wherein the mass ratio of deionized water to absolute ethanol is 3:1; after standing for stratification, take the supernatant at 45 Evaporate under vacuum at ℃ to remove ethanol, then adjust the pH to neutral with dilute hydrochloric acid after cooling; then add acetone to the neutral solution, wherein the mass ratio of acetone to deionized water is 1.5:1, resulti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com